Dead-point-free oscillating hydrofoil type tidal current energy power generation structural body

A technology with no dead point and tidal energy, applied in the directions of hydropower generation, ocean energy power generation, engine components, etc., it can solve the problems of increasing design difficulty, high starting flow rate, poor replaceability, etc., achieving easy modular assembly and reducing manufacturing costs. , The effect of convenient overall disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

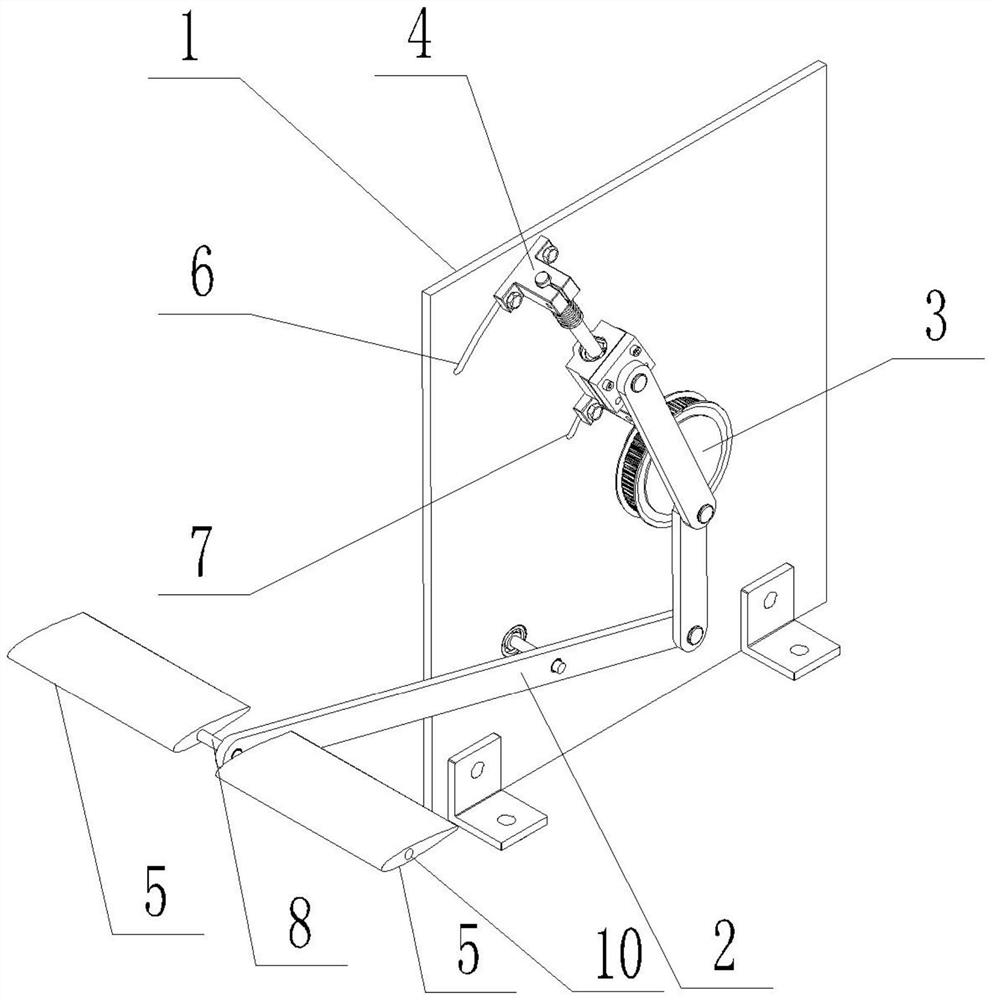

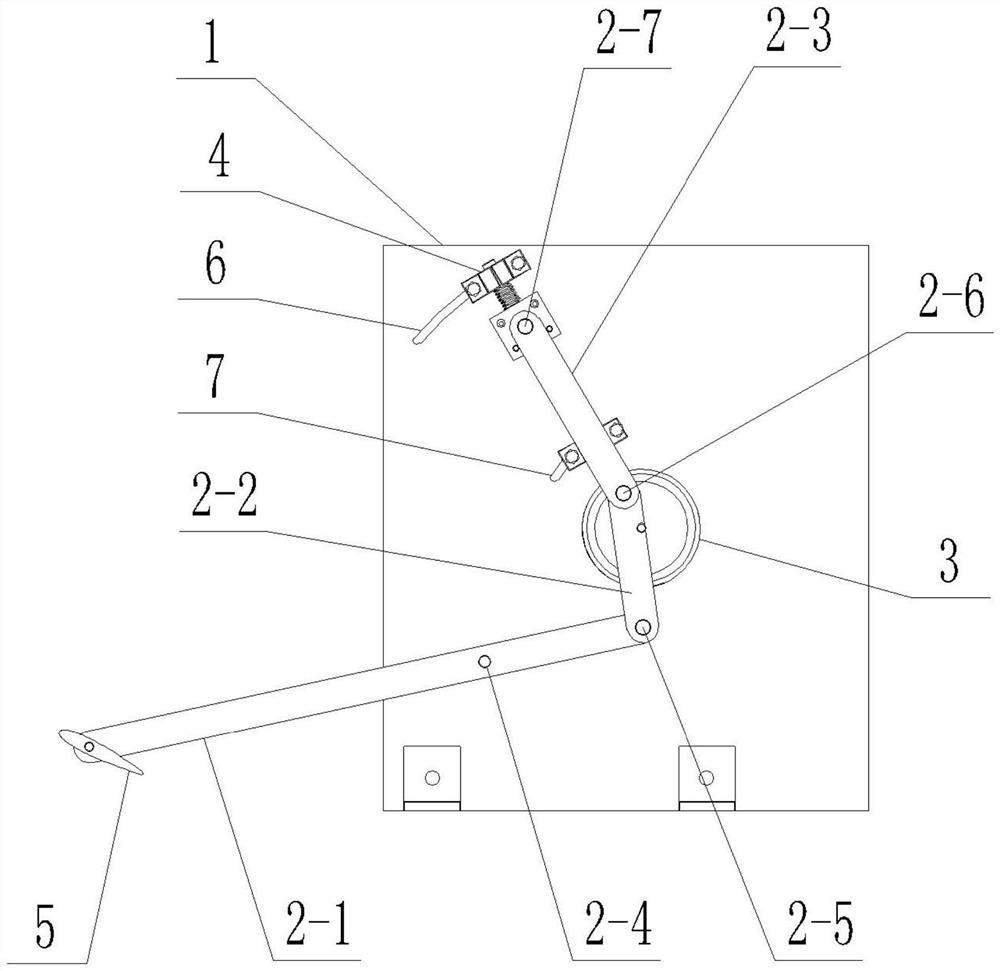

[0032] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, this specific embodiment adopts the following technical solutions. This embodiment includes a vertical plate 1, a transmission rod 2, a runner 3, an elastic slider body 4 and two hydrofoils 5, and the vertical plate 1 is vertically arranged. The transmission rod 2, the runner 3 and the elastic slider body 4 are all arranged on the same side of the vertical plate 1, the elastic slider body 4 is slidingly matched with the vertical plate 1, and the runner 3 is arranged under the elastic slider body 4;

[0033] The transmission rod 2 includes a long rod body 2-1, a middle rod body 2-2, a short rod body 2-3, a first shaft body 2-4, a second shaft body 2-5, a third shaft body 2-6 and a fourth shaft body The shaft body 2-7, one end of the long rod body 2-1 is hinged with two hydrofoils 5, the long rod bod...

specific Embodiment approach 2

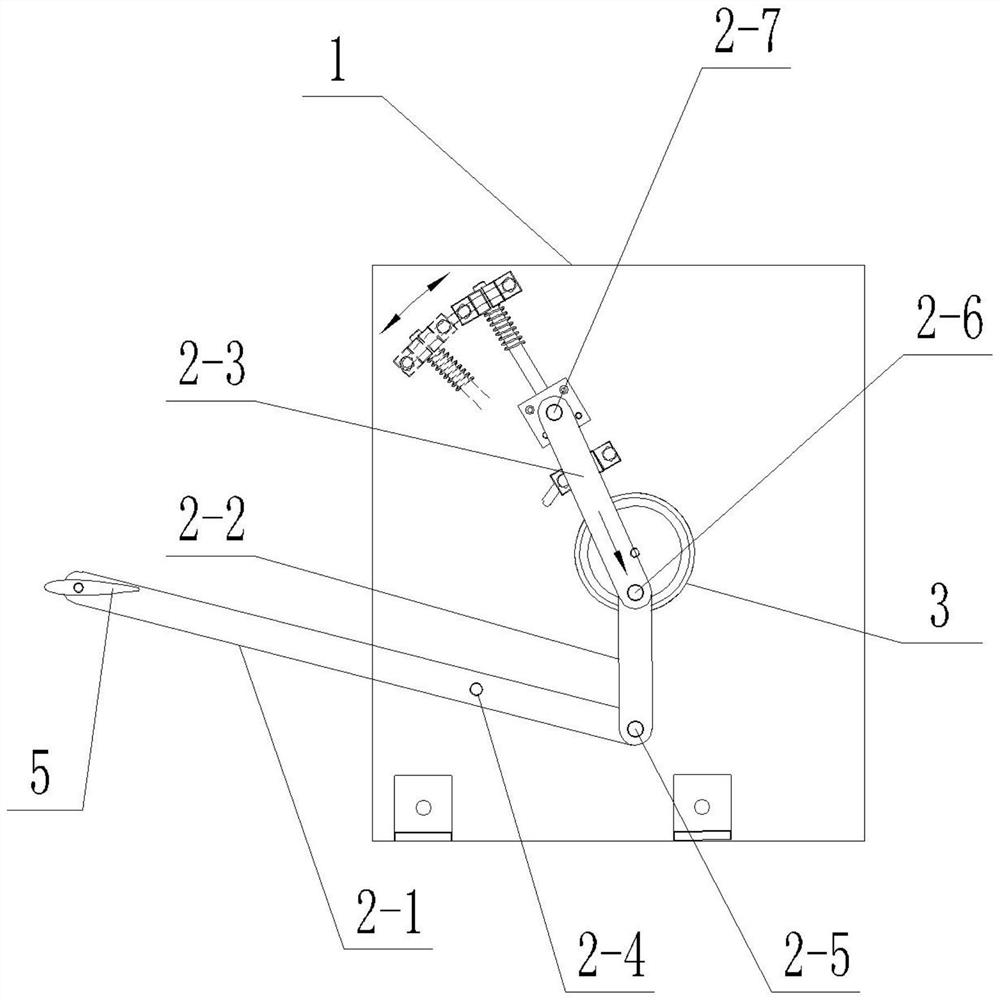

[0039] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The elastic slider body 4 includes an upper slide seat 4-1, a linear optical axis 4-2, a slide block 4-3, and a lower seat 4-4. , upper spring 4-5 and lower spring 4-6, described upper sliding seat 4-1 and lower sliding seat 4-4 are arranged on the side of vertical plate 1 successively from top to bottom, upper sliding seat 4-1 and lower sliding seat A linear optical axis 4-2 is arranged between 4-4, the slider 4-3 is set on the linear optical axis 4-2 and it reciprocates along the length direction of the linear optical axis 4-2, and the upper spring 4-5 is set on the On the linear optical axis 4-2 and it is between the upper slide seat 4-1 and the slider 4-3, the lower spring 4-6 is set on the linear optical axis 4-2 and it is located between the lower seat 4-4 and the slide block Between 4-3.

specific Embodiment approach 3

[0040] Specific embodiment three: this embodiment further defines the first arc-shaped slideway 6 matching the upper slide 4-1 on the side of the vertical plate 1 of the specific embodiment one or two, and the side surface of the vertical plate 1 is processed with Cooperate with the second curved slideway 7 of the sliding seat 4-4.

[0041] In this embodiment, the torque to overcome the dead point can be adjusted. The sliding fit relationship between the elastic slider body 4 and the vertical plate 1 is specifically that the upper sliding seat 4-1 is installed on the first arc of the vertical plate 1 through a plurality of first bolts. In the slideway 6, the sliding seat 4-4 is installed in the second arc-shaped slideway 7 of the vertical plate 1 through a plurality of second bolts.

[0042] In this embodiment, the position of the upper sliding seat 4-1 is changed by adjusting the fastening position of a plurality of first bolts in the first arc-shaped slideway 6, thereby real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com