Electrode for use in a battery and method of making the same

A manufacturing method and electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as difficulty in manufacturing ultra-thin batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

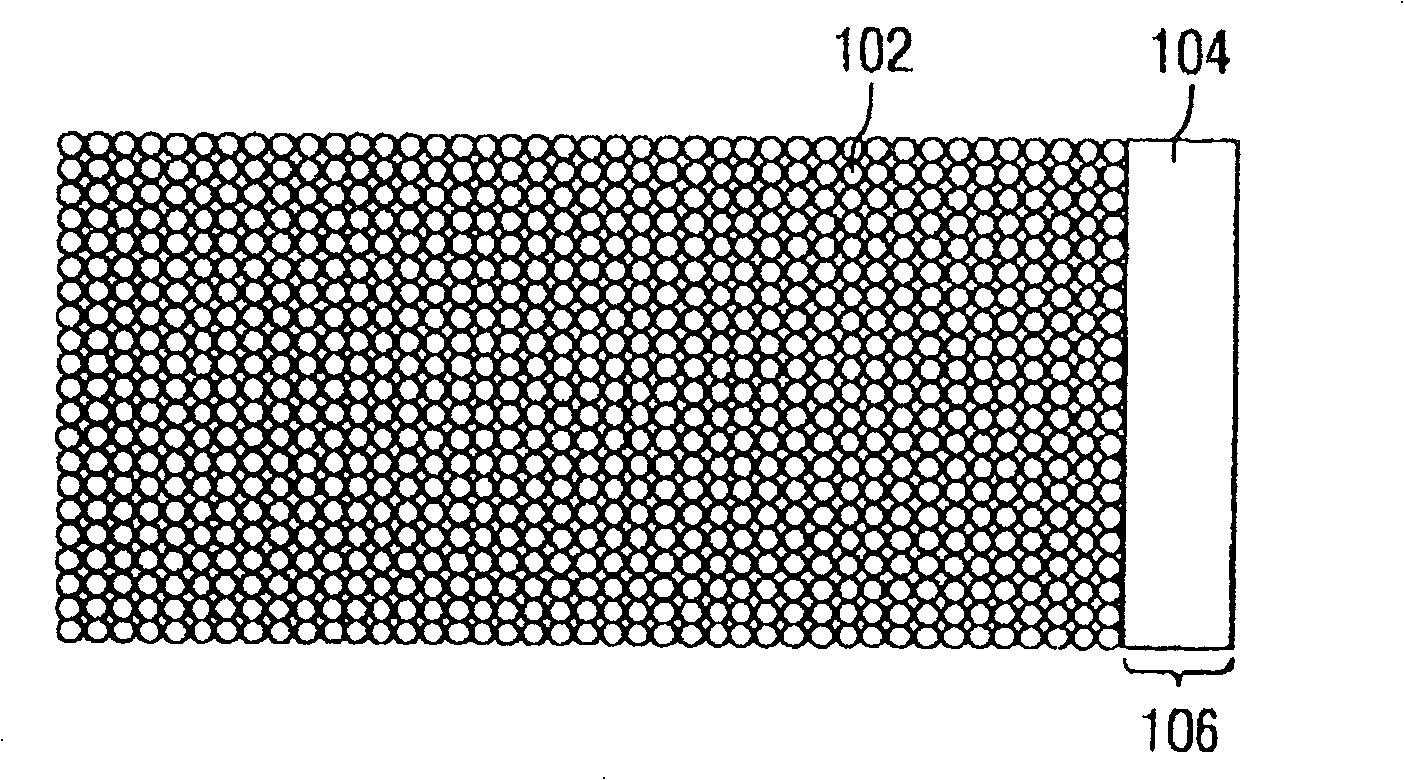

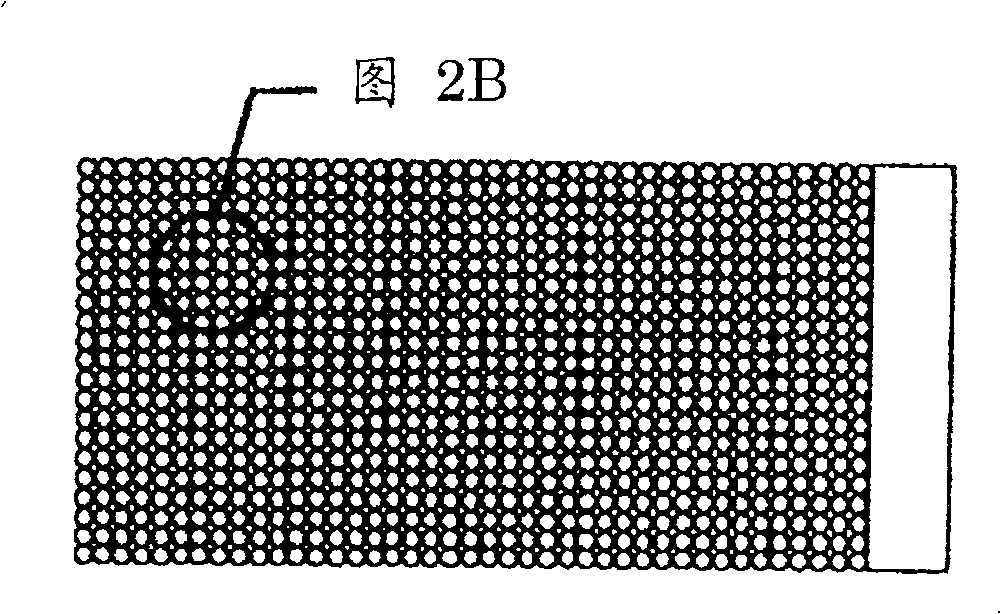

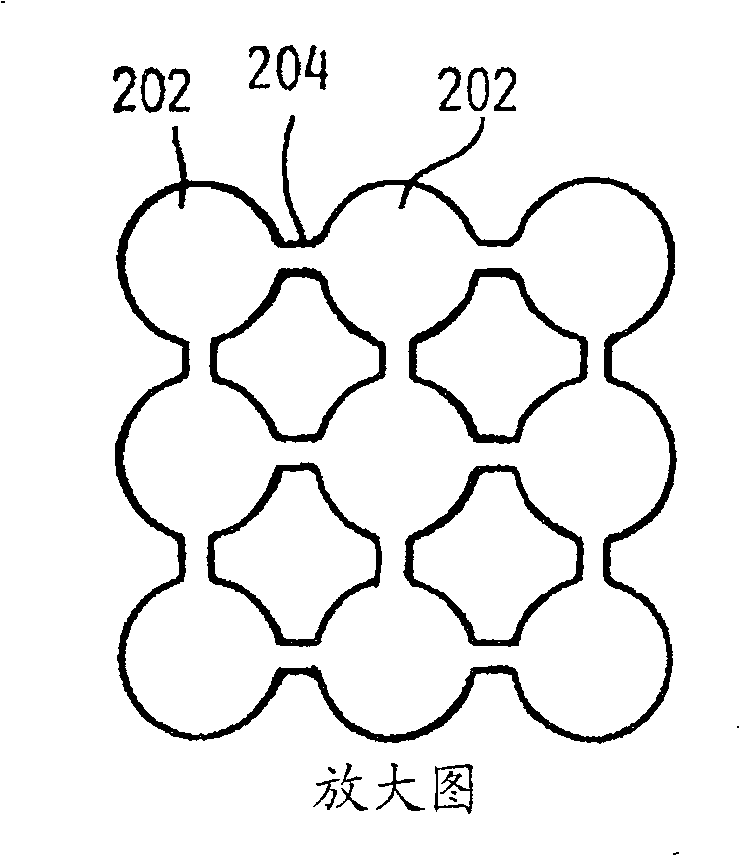

[0020] The invention also discloses a method for preparing an electrode, the method comprising the steps of: manufacturing at least one electrode ink composition containing electrode active material particles; on an electric appliance to form a film; and dry the deposited film. The first electrode ink comprises an electrode active material alone or in combination with a conductive material. The method also includes depositing a second electrode ink composition comprising a binder material onto the substrate from an inkjet device.

[0021] A method of forming an electrode having a highly uniform film thickness of a catalyst film layer using an inkjet system is also considered. Disclosed in the present invention is a method in which an electrode ink is ejected from an inkjet system to form a catalyst layer, the electrode ink comprising an electrode active material constituting an electrode catalyst layer (hereinafter referred to simply as a "catalyst layer"), a conductive agen...

Embodiment 1

[0064] A first electrode ink composition was prepared according to the method outlined in the present invention.

[0065] 85 grams of spinel manganese with a particle size of 1 μm was weighed as a positive electrode material, 10 grams of carbon black with a particle size of 50 nm was used as a conductive agent, and 5 grams of polyoxystearylamine was used as a dispersant, and mixed. 140 grams of NMP was added and dispersed as a solvent to obtain a composition viscosity of 100 cP.

[0066] Prepare the second electrode ink composition according to the method described in the present invention.

[0067] Weigh 5 grams of PVdF as binder and add 10 grams of NMP to obtain a viscosity of 100 cP.

[0068] To form the catalyst layer, the first electrode ink composition containing the positive electrode material and the second electrode ink composition containing the binder material were sprayed onto the aluminum foil by an inkjet device to form the catalyst layer. 51 sprays are require...

Embodiment 2

[0133] The battery according to the alternative embodiment disclosed in the present invention will be further described in detail using examples. In the following application examples, unless otherwise specified, the following materials were used as lithium salt, positive electrode active material, and negative electrode active material.

[0134] Lithium salt: LiN(SO 2 C 2 f 5 ) 2 (The following will be abbreviated as "BETI")

[0135] Positive electrode active material: spinel LiMn 2 o 4

[0136] Negative electrode active material: crushed graphite (average particle size: 0.2 μm)

[0137] In addition, the preparation of the positive electrode ink composition and the negative electrode ink composition, printing using an inkjet system, and battery assembly were performed in dry air with a dew point of -30°C or lower.

[0138] Preparation of positive electrode ink

[0139] In order to prepare the positive electrode ink composition, the positive electrode active materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com