Back flow prevention valve

A technology of check valves and check valves, which is applied to control valves, valve devices, valve details, etc., can solve problems such as damage to cleaning devices, and achieve the effect of small structural volume and simplified spare parts storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

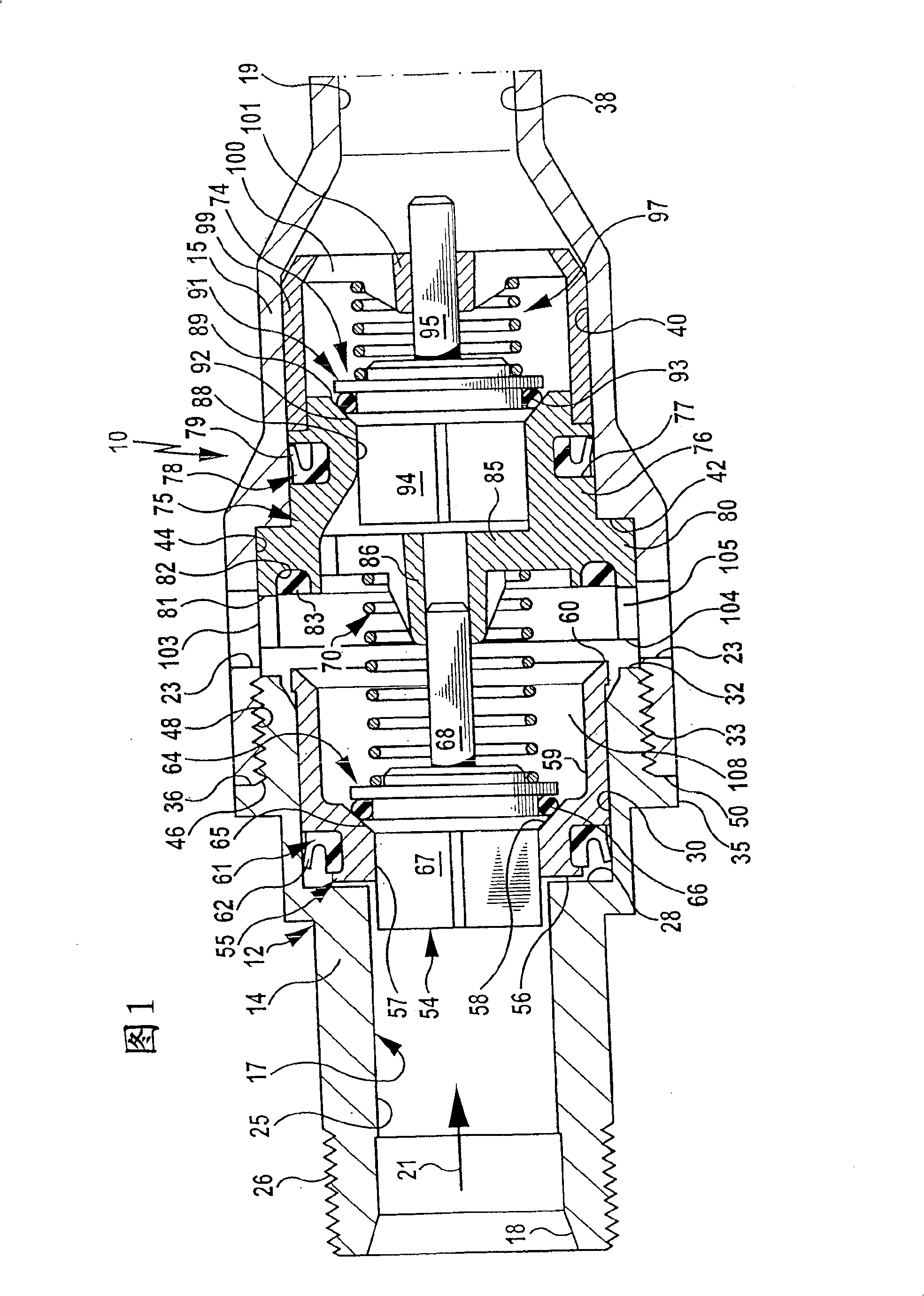

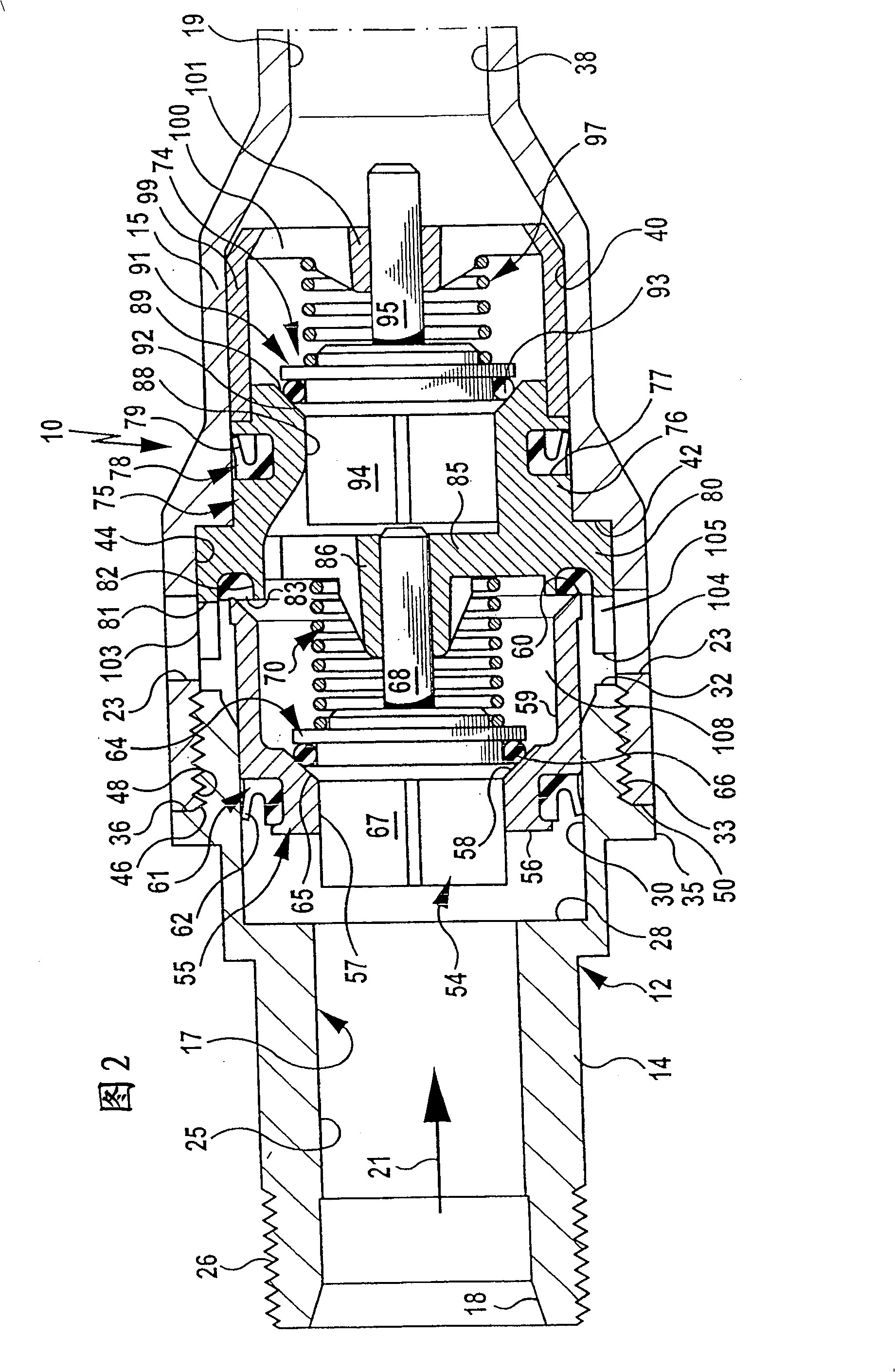

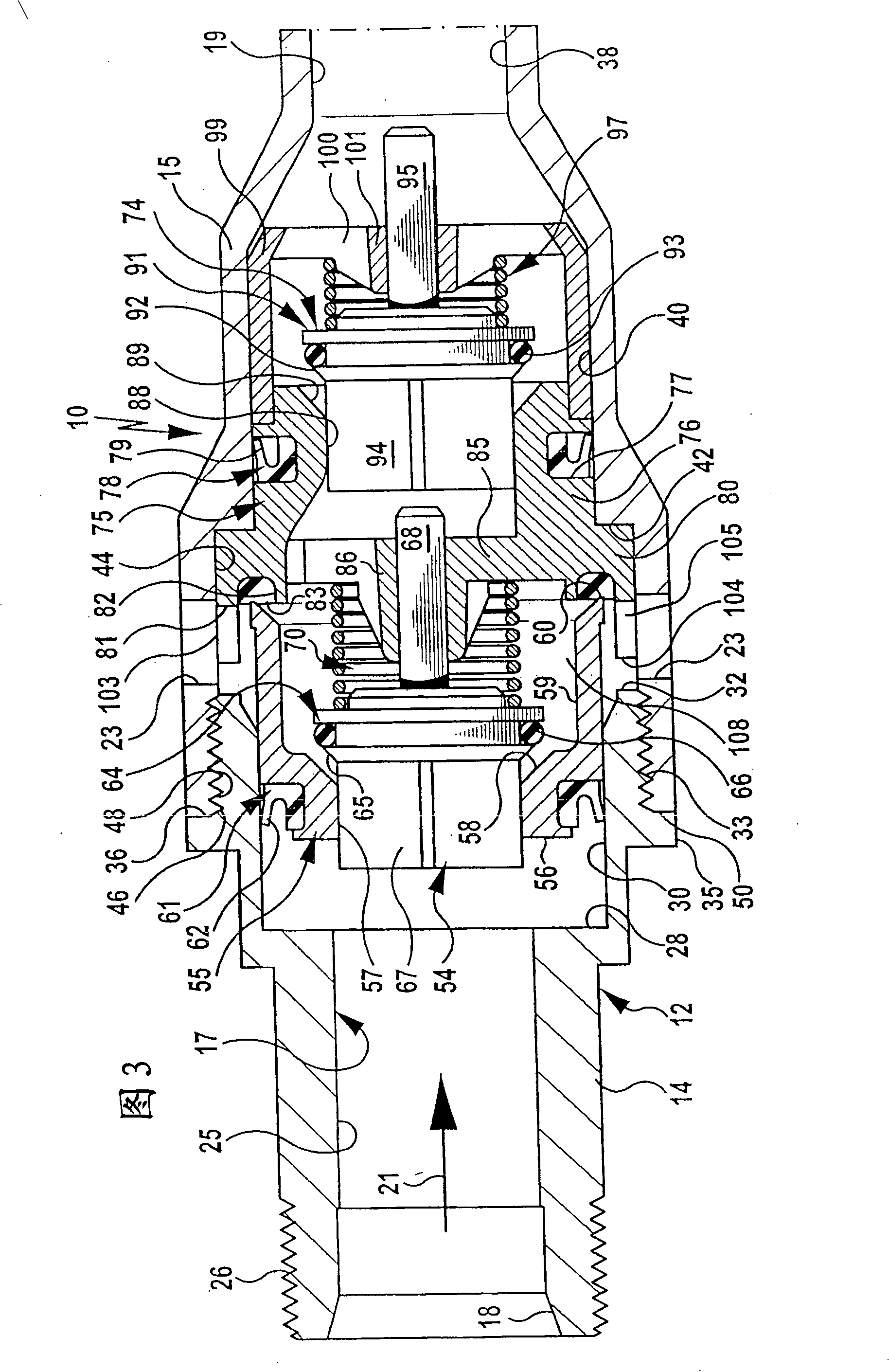

[0025] There is shown a check valve, generally indicated at 10, comprising a two-part housing 12 having a first housing part 14 and a second housing part 15 and enclosing a flow passage 17 communicating with An inlet 18 and an outlet 19 , wherein at least one, preferably a plurality of leakage openings distributed along the circumference of the housing 12 are formed in the housing 12 approximately centrally in the flow direction 21 between the inlet 18 and the outlet 19 twenty three.

[0026] The first housing part 14 constitutes the form of a pipe part and includes an inlet passage 25 connected on the inlet 18, which has an external thread 26 on the outside for connecting the non-return valve 10 on a drinking water supply pipe and via A step 28 merges into a connecting portion 30 whose inner diameter is greater than that of the inlet channel 25 and which terminates with an end face 32 whose plane normal is situated parallel to the flow direction 21 . The part of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com