Method for direct joint of ethylen-propylene rubber and cast iron

A technology of ethylene-propylene rubber and cast iron, which is applied in the direction of cells, electrolysis, organic chemistry, etc., can solve the problems of changing physical-mechanical properties, and achieve the effects of easy popularization and application, simple process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The substrate metal used for organic coating is thin-wall tough ductile iron, and the size of the substrate metal in this embodiment is 30×50×4.5 (mm). The chemical composition (wt%) is 3.71C, 2.35Si, 0.19Mn, 0.044Mg, 0.035 Cu, 0.025P and 0.006S.

[0034] Step 1: Organic Coating

[0035] Firstly, the cast iron samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30 °C, and then carried out organic coating treatment. The specific process conditions and steps are as follows:

[0036] 1. The organic coating adopts a three-electrode working method, the working electrode is a cast iron sheet, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0037] 2. The electrolyte solution used in organic coating is composed of the following substances:

[0038]

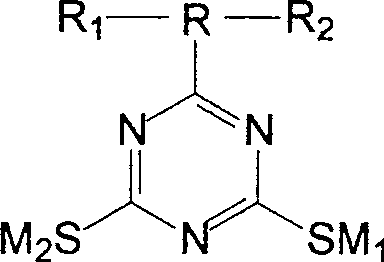

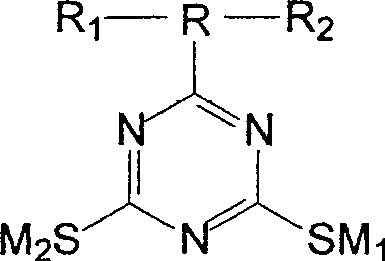

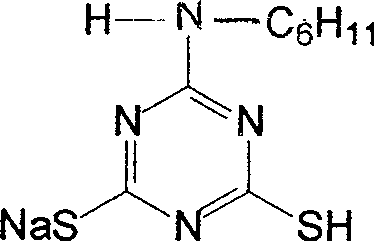

[0039] 0.5mmol / l triazine organic compound salt containing the above functional groups, 1mol / ...

Embodiment 2

[0047] The substrate metal used for organic coating is thin-wall tough ductile iron, and the size of the substrate metal in this embodiment is 30×50×4.5 (mm). The chemical composition (wt%) is 3.71C, 2.35Si, 0.19Mn, 0.044Mg, 0.035 Cu, 0.025P and 0.006S.

[0048] Step 1: Organic Coating

[0049] Firstly, the cast iron samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30 °C, and then carried out organic coating treatment. The specific process conditions and steps are as follows:

[0050] 1. The organic coating adopts a three-electrode working method, the working electrode is a cast iron sheet, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0051] 2. The electrolyte solution used in organic coating is composed of the following substances:

[0052]

[0053] 1mmol / l triazine organic compound salt containing the functional groups shown in the ...

Embodiment 3

[0061] The substrate metal used for organic coating is thin-wall tough ductile iron, and the size of the substrate metal in this embodiment is 30×50×4.5 (mm). The chemical composition (wt%) is 3.71C, 2.35Si, 0.19Mn, 0.044Mg, 0.035 Cu, 0.025P and 0.006S.

[0062] Step 1: Organic Coating

[0063] Firstly, the cast iron samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30 °C, and then carried out organic coating treatment. The specific process conditions and steps are as follows:

[0064] 1. The organic coating adopts a three-electrode working method, the working electrode is a cast iron sheet, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0065] 2. The plating solution used in organic coating is composed of the following substances:

[0066]

[0067] 2.5mmol / l triazine organic compound salt containing the above functional groups, 5mol / l s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com