Protecting sleeve for thread in petroleum steel pipe and making process thereof

A technology for thread protection and petroleum steel pipes, which is applied in the direction of sustainable manufacturing/processing, packaging recycling, closing, etc., can solve the problems of weakening the impact resistance of the protective sleeve, disengagement of the two sets, and failure to achieve the protection effect, so as to strengthen the impact resistance Capability, easy installation and disassembly, avoiding the effect of mutual rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

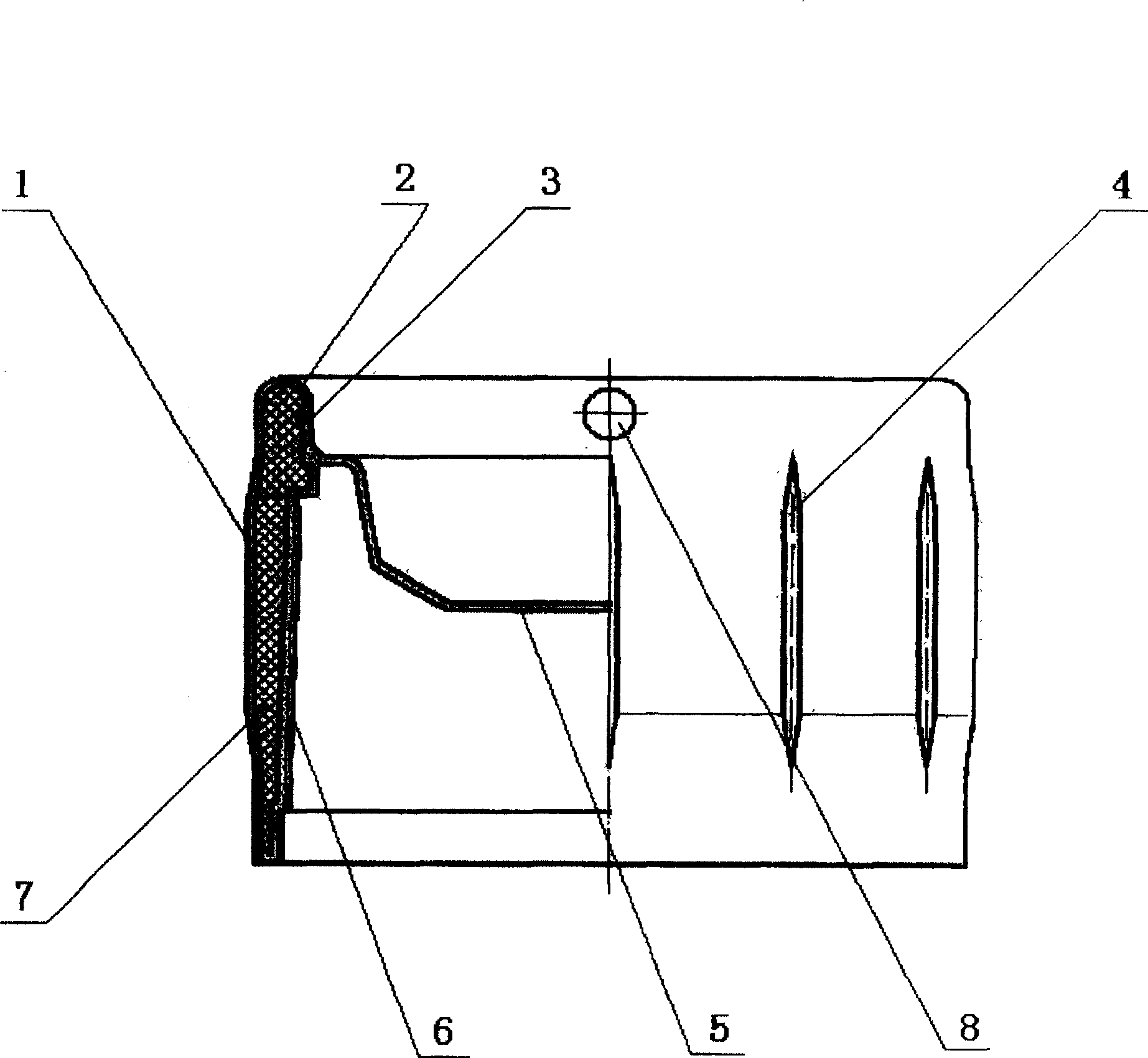

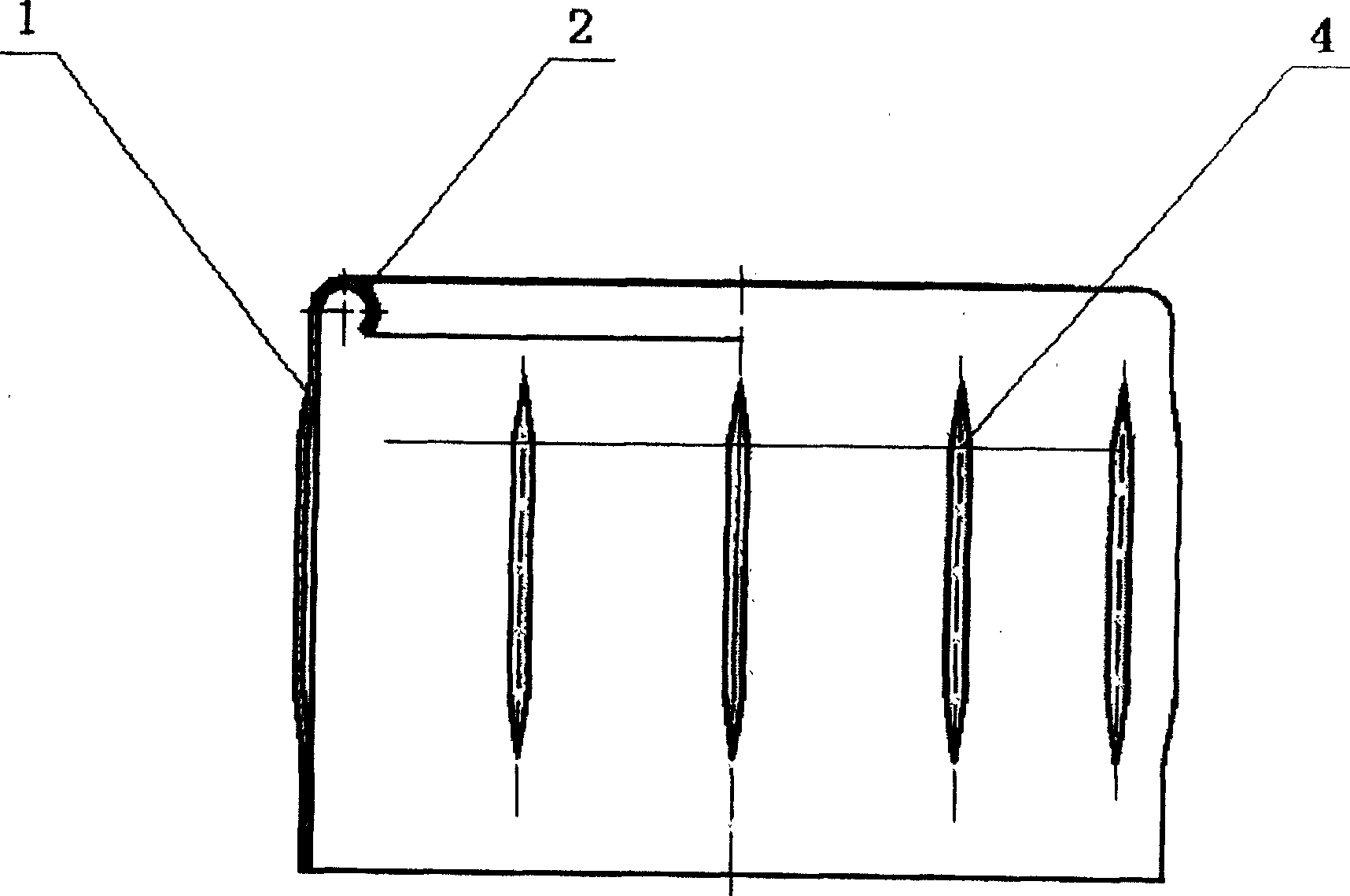

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

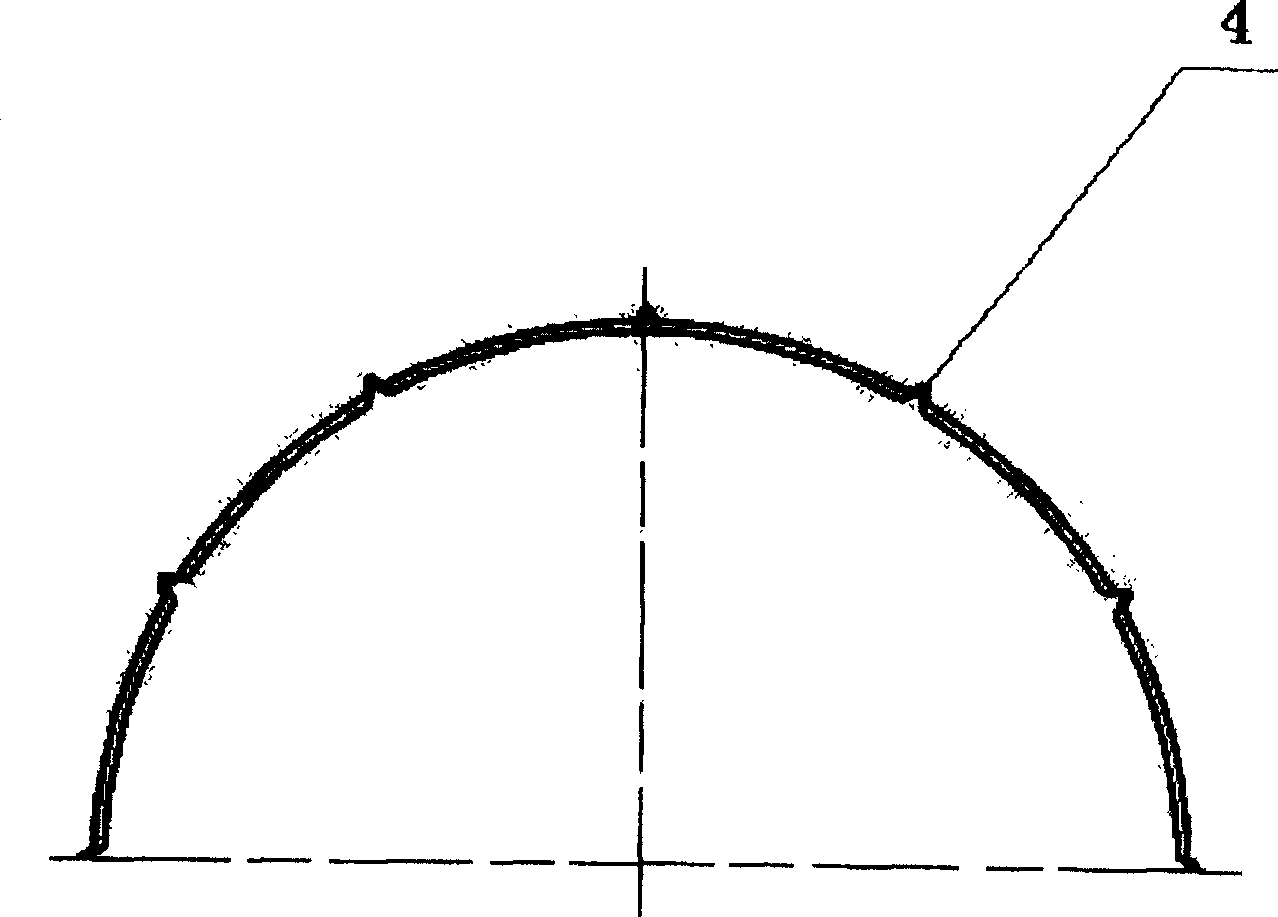

[0034] figure 1 , figure 2 , image 3 The structure of the present invention and the structure of the metal sleeve in the present invention are shown respectively. It can be seen from the figure that the oil steel pipe thread protection sleeve of the present invention includes a metal sleeve 1 made of steel plate or iron plate and a plastic sleeve 6 arranged in the metal sleeve 1 . The metal sleeve 1 is hollow and has a flange 2 on the top; the plastic sleeve 6 is barrel-shaped, and the top 5 is integrally molded with the wall; the flange 2 of the metal sleeve 1 is connected to the The setback 3 at the edge of the top 5 of the plastic sleeve 6 is handed over, and the inner wall of the plastic sleeve 6 is provided with an internal thread, and the internal thread is adapted to the external thread at the end of the steel pipe to be protected. In order to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com