Steady state detecting method for use in tobacco processing course

A technology of processing process and detection method, applied in the directions of tobacco, tobacco preparation, and comprehensive factory control, etc., can solve the problems of inability to effectively identify factors of tobacco quality, inability to quantitatively and qualitatively analyze tobacco processing, and achieve high accuracy and simple method. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

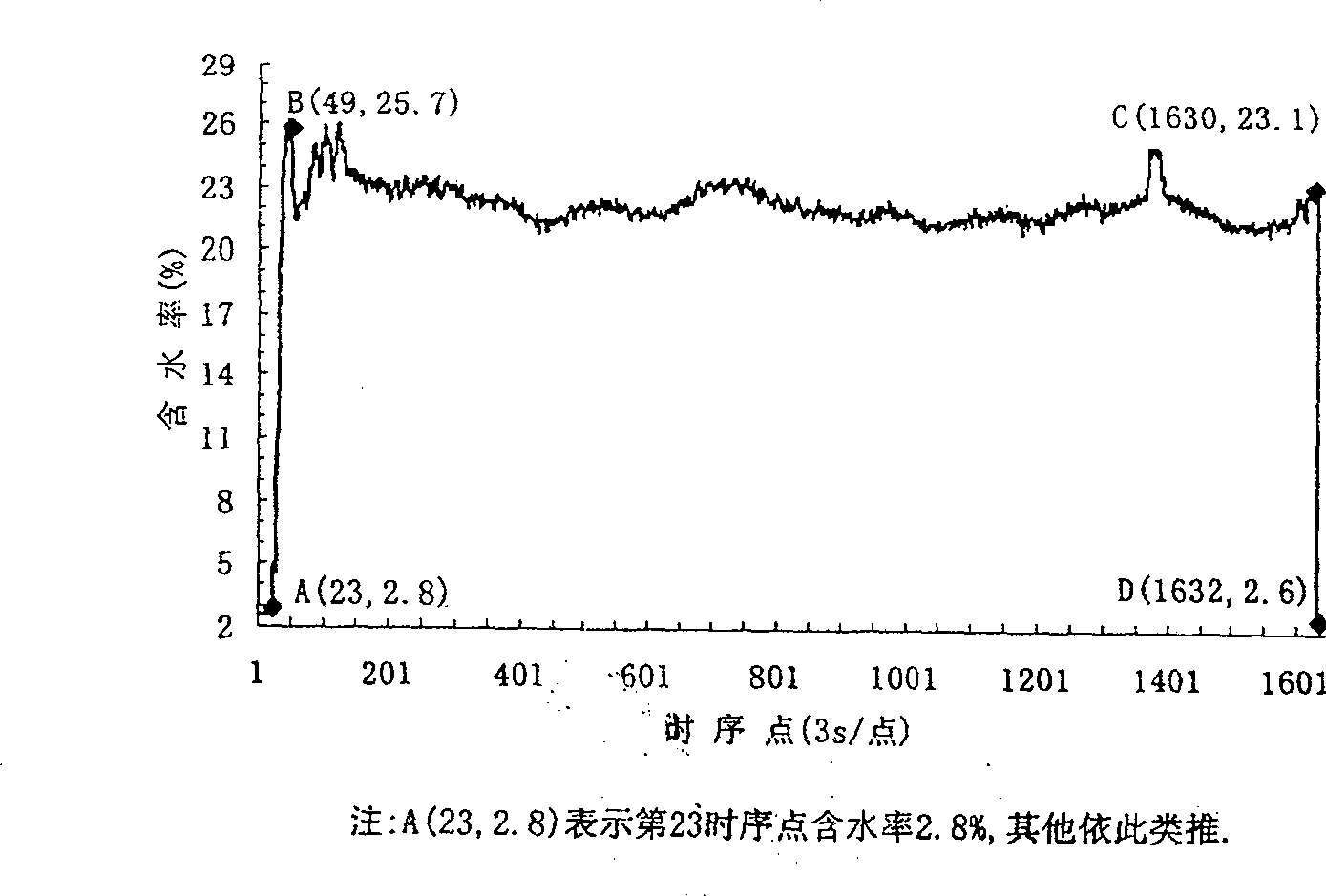

[0032] For example, the design value of the outlet moisture content index in the feeding process of brand A tobacco leaves is (22.0±1.0)%. The outlet moisture content of a certain test batch of this brand is collected, and the collection frequency is 20 times / min, and the centralized sampling (50kg) from the feeder inlet is once during the processing. The time-series broken line of the outlet moisture content is shown in figure 1 .

[0033] figure 1 It shows that ① points A and D and their corresponding timing points 23 and 1632 are the start and end time points of the processing process, and the moisture content data in the processing process: 1632-23 = 1609 pieces, and the total time is 80.45 minutes; ② The moisture content between points A and B The curve is the initial stage of the process, and the moisture content curve between points C and D is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com