Inner pin jointing tape coiling and tape coiling support packaging structure using the same

A technology of inner pins and pins, which is applied in the field of flexible wafer carriers to achieve the effects of improving fracture resistance, enhancing resistance to twisting, and being easy to manufacture and form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the inner lead bonding reel according to the present invention and the reel carrying tape using the reel are described below. The specific implementation, structure, features and functions of the packaging structure are described in detail below.

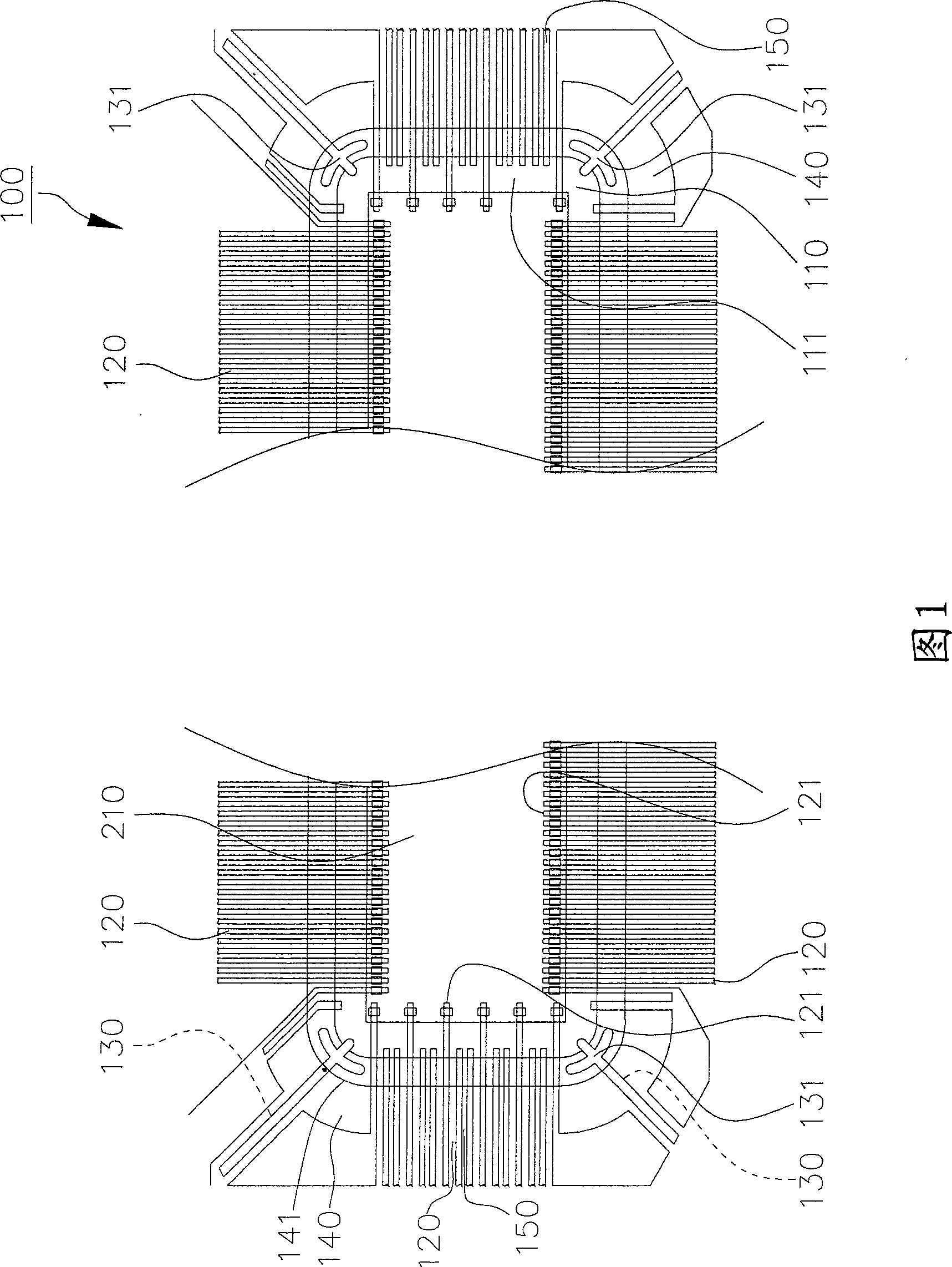

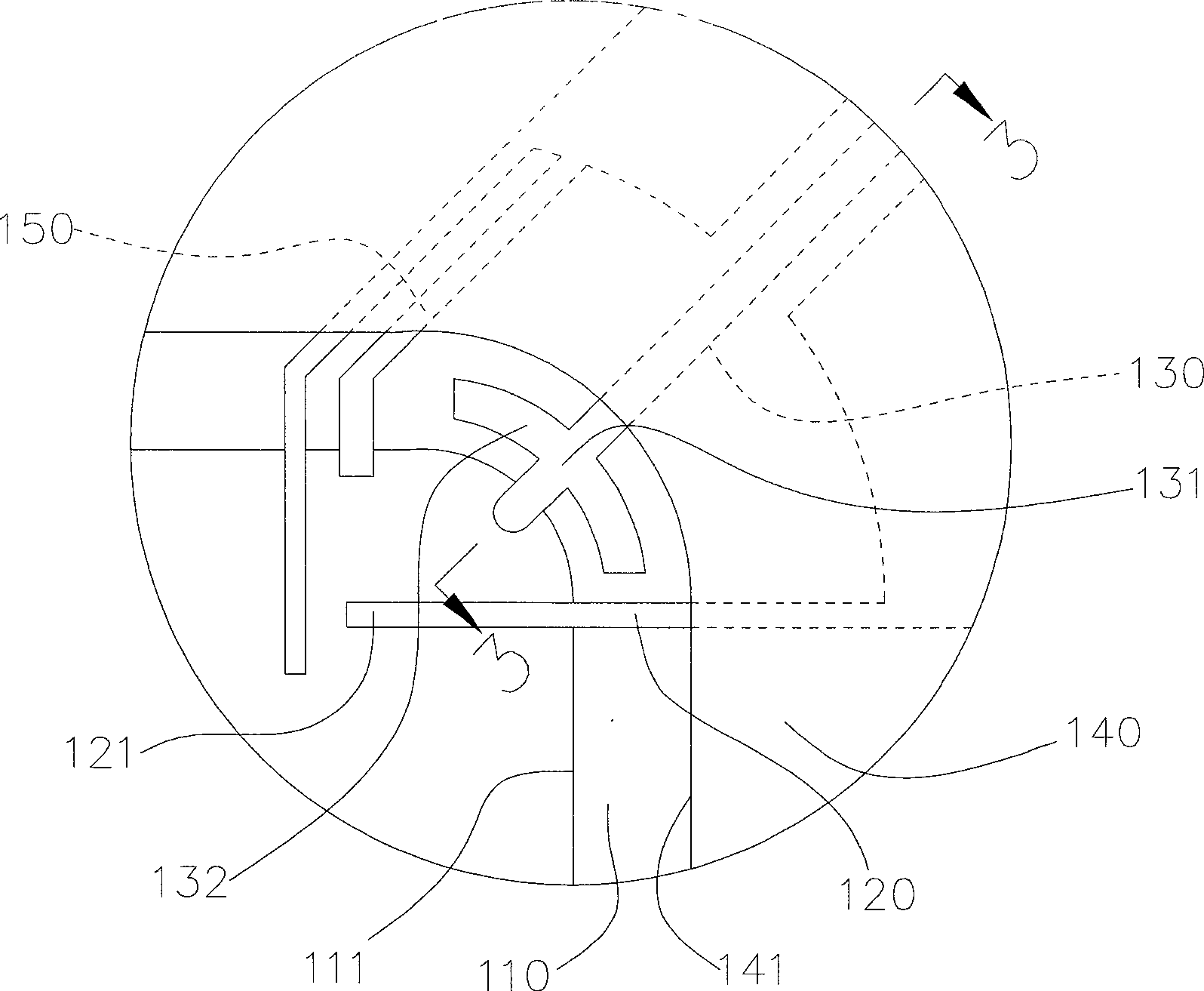

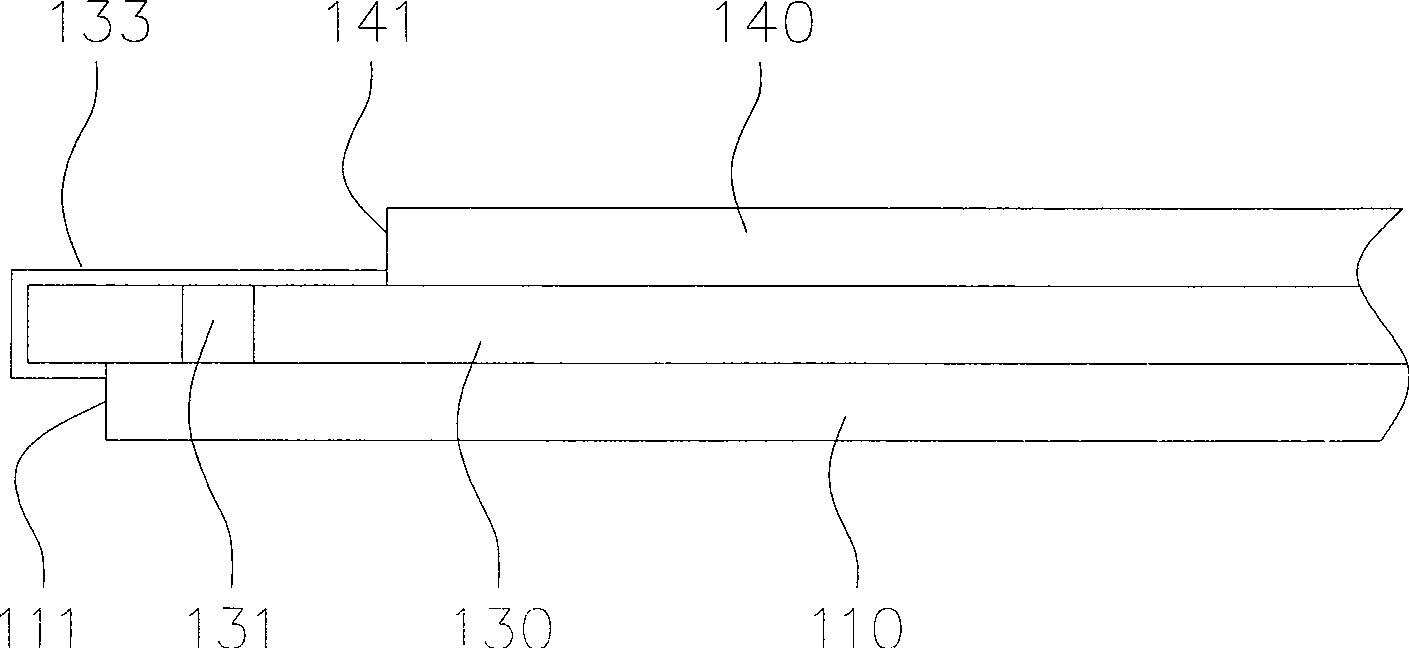

[0057] Please refer to Figure 1(a), Figure 1(b), figure 2 and image 3 As shown, it is according to a specific embodiment of the present invention, and Fig. 1 is a schematic top view of an inner pin bonding tape, figure 2 is a partial top view diagram of the inner pin bonding tape on the reinforcing pin, image 3 is a schematic cross-sectional view of the inner pin bonding tape along one of the reinforcing pins.

[0058] The inner pin bonding tape 100 of a specific preferred embodiment of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com