A tea forming bag kneading machine

A kneading machine and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of not being able to achieve the shape of manual tea kneading, the force cannot be automatically adapted to change, and the effect of kneading cannot be achieved, and the design of the mechanical structure is ingenious , Avoid excessive kneading force and improve the effect of kneading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

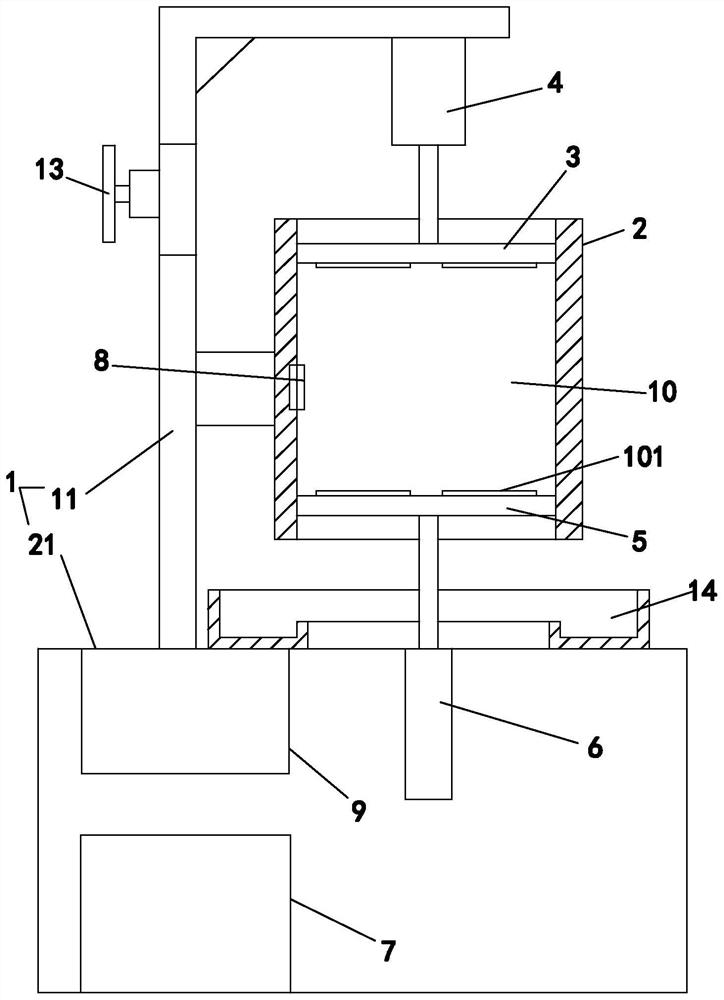

[0028] Embodiment 1, a kind of tea forming wrapping machine disclosed in this embodiment, such as figure 1 As shown, it includes a frame 1, an accommodating cylinder 2, a first cover 3, a first driving device 4, a second cover 5, a second driving device 6, a hydraulic system 7, a pressure detection device 8 and a control system 9, The position connection relationship of each part will be described in detail below in conjunction with the accompanying drawings.

[0029] The frame 1 described in the figure includes a base 11 and an extension frame 12, and the hydraulic system 7 and the control system 9 are arranged in the base 11 so that they are not exposed, and the appearance of the machine is clean.

[0030] The accommodating cylinder 2 is a hollow cylindrical structure with upper and lower openings. As shown in the figure, its cylinder body is erected on the extension frame 12 of the frame 1 and fixed.

[0031] The first cover plate 3 is set corresponding to the upper openin...

Embodiment 2

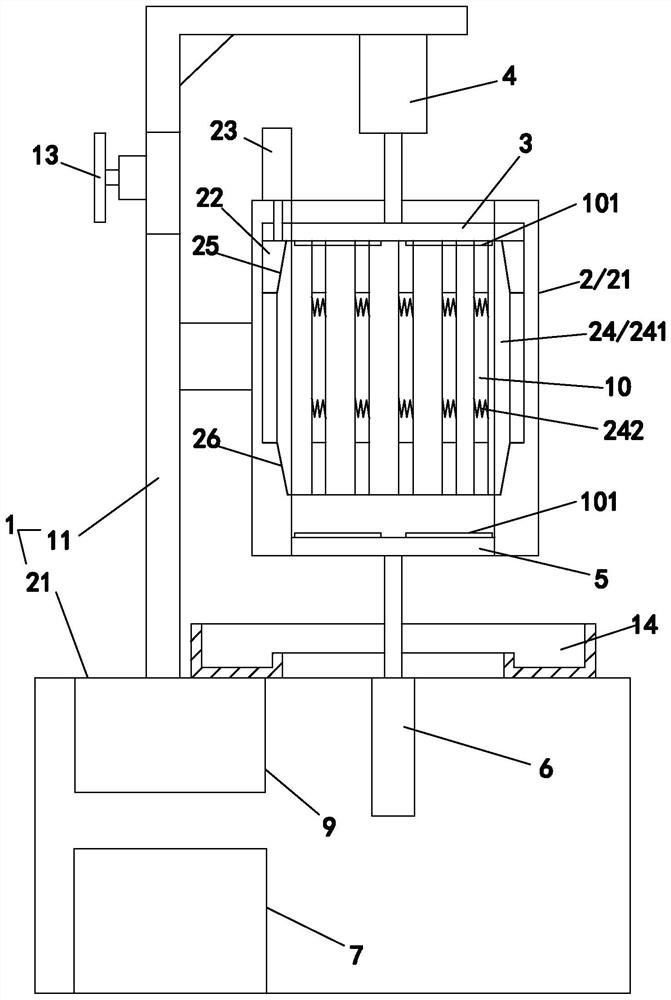

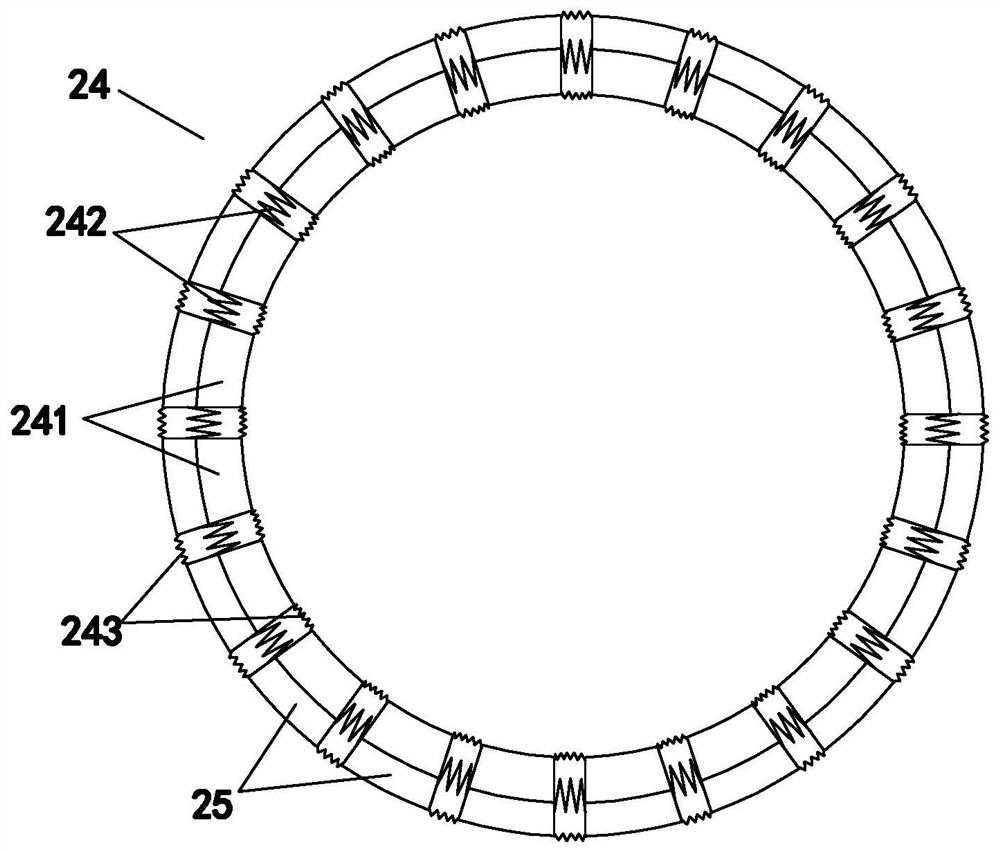

[0036] Embodiment 2, the difference between embodiment 2 and embodiment 1 is that the barrel body of the accommodating cylinder 2 is a structural setting that can automatically scale and change the space of the kneading chamber 10, specifically as figure 2 As shown, the accommodating cylinder 2 includes a fixed outer cylinder 21, a push cylinder 22, a push cylinder 23 and a zoom cylinder 24. The zoom cylinder 24 is nested in the fixed outer cylinder 21. The specific structure of the zoom cylinder 24 is as follows: figure 2 and image 3As shown, it is composed of a plurality of splicing blocks 241 axially enclosed and connected by springs 242 between two splicing blocks 241, and a telescopic sleeve 243 is provided between two splicing blocks 241 to cover the space between them and The spring can prevent the tea leaves from falling into the interval space when kneading, which will not only affect the zooming and kneading work, but also damage the tea leaves. The pushing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com