Method for driving element extending along longitudinal axis

A technology in the direction of the longitudinal axis and the longitudinal axis, which is applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., and can solve problems such as unrealizable and impossible to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

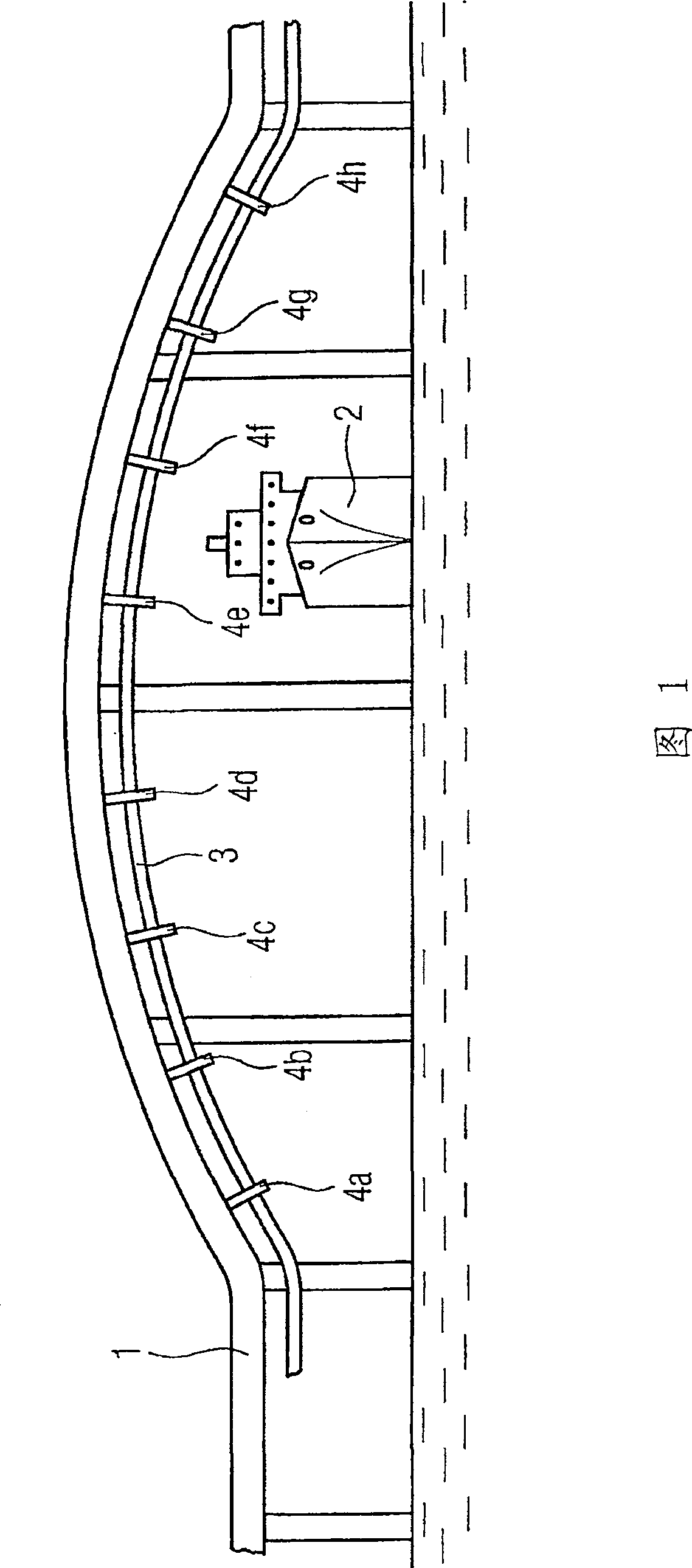

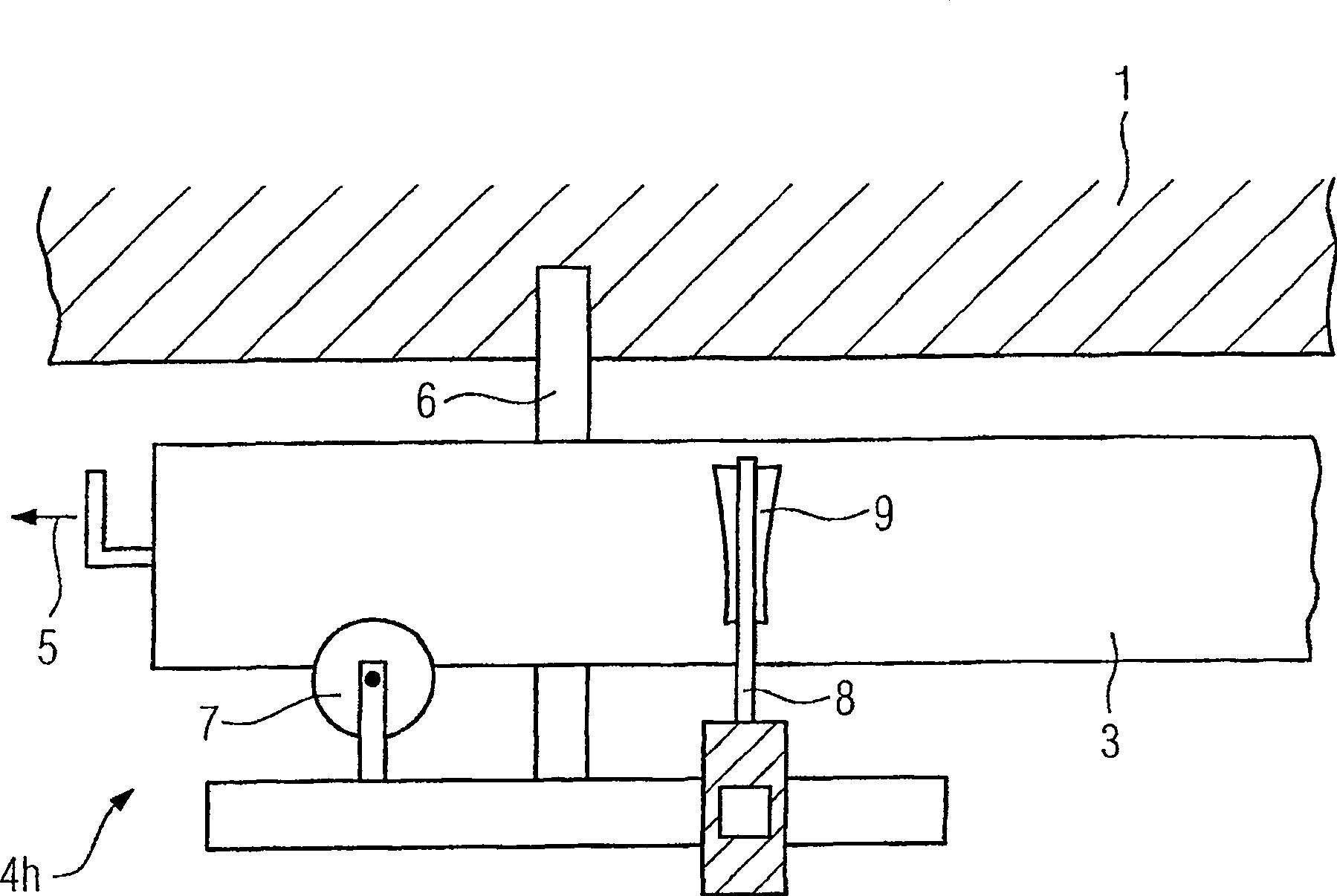

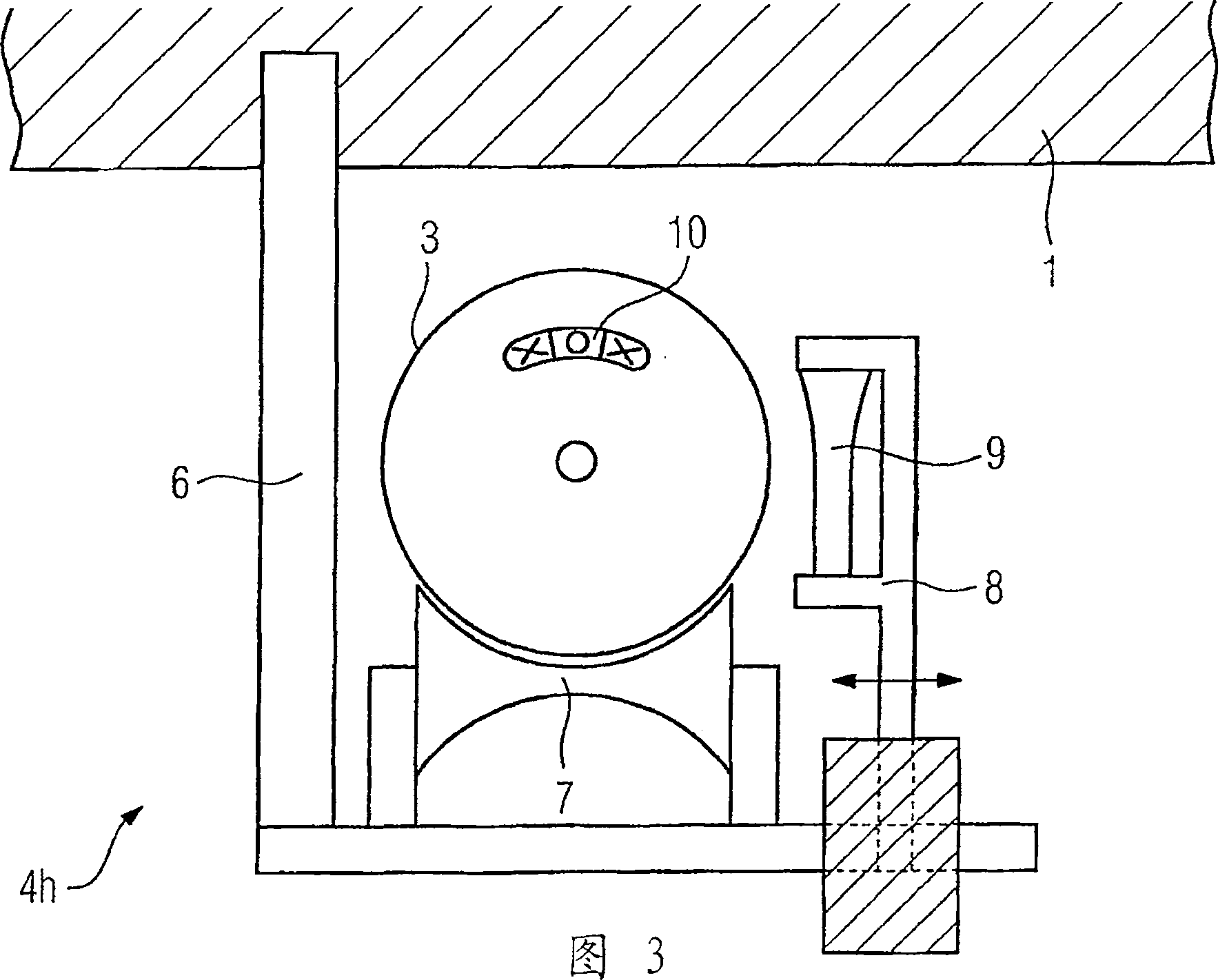

[0026] Figure 1 shows a bridge 1 spanning a water surface area. The bridge 1 has curved arches to enable tall ships 2 to pass. The gas insulated electrical conductor 3 needs to be laid on the bridge 1 according to the arc of the bridge. For this purpose, a plurality of roller bearing arrangements 4 a , 4 b , 4 c , 4 d , 4 e , 4 f , 4 g , 4 h are provided on the bridge 1 . Due to bending, the gas-insulated electrical conductor 3 can generate mechanical stresses that cause it to rotate about the longitudinal axis. The gas-insulated electrical conductor 3 can be designed essentially to consist of, for example, a metallic outer sleeve, inside which the actual electrical conductor is arranged. The electrical conductor is supported on the tubular outer housing by means of an electrically insulating support element. The interior of the gas-insulated electrical conductor 3 is filled with an insulating gas under operating conditions. The gas-insulated electrical conductor 3 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com