Rapid-construction method for rapid change of small-section into large-section tunnel

A construction method and large-section technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as unfavorable mucking, feeding, narrow working face of small pilot pits, and difficulty in guaranteeing the construction period, so as to achieve good social and economic benefits. Benefits, strong construction safety and stability, and reasonable support measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

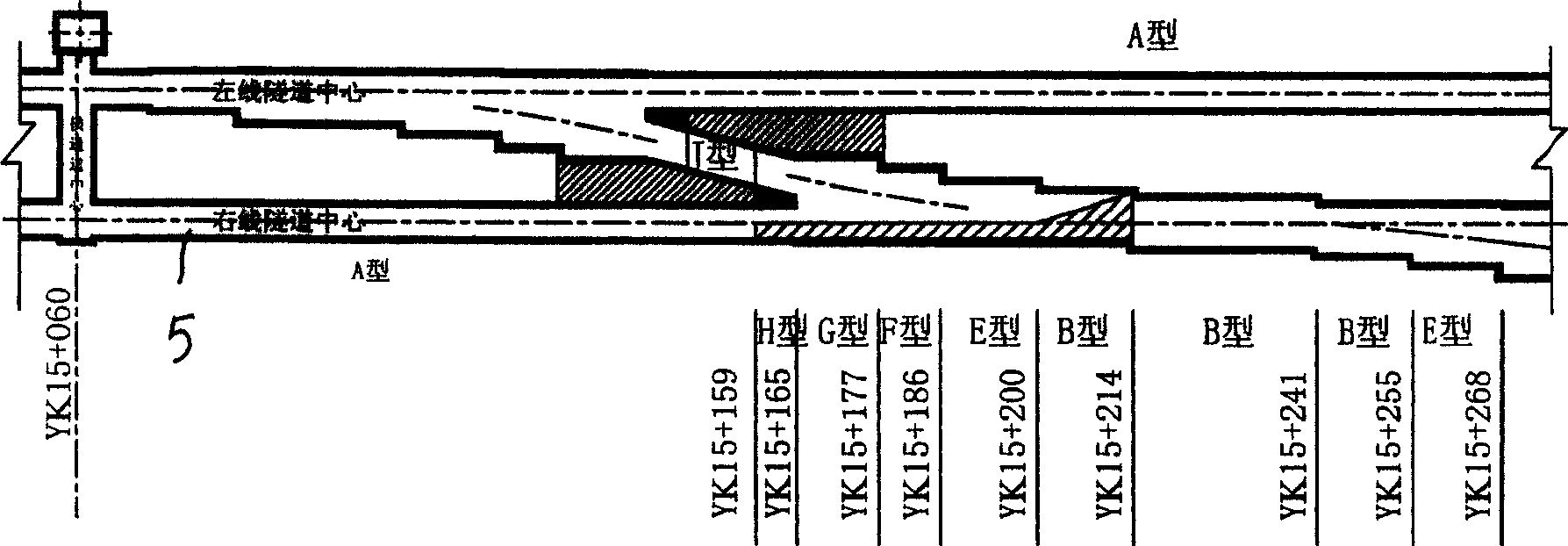

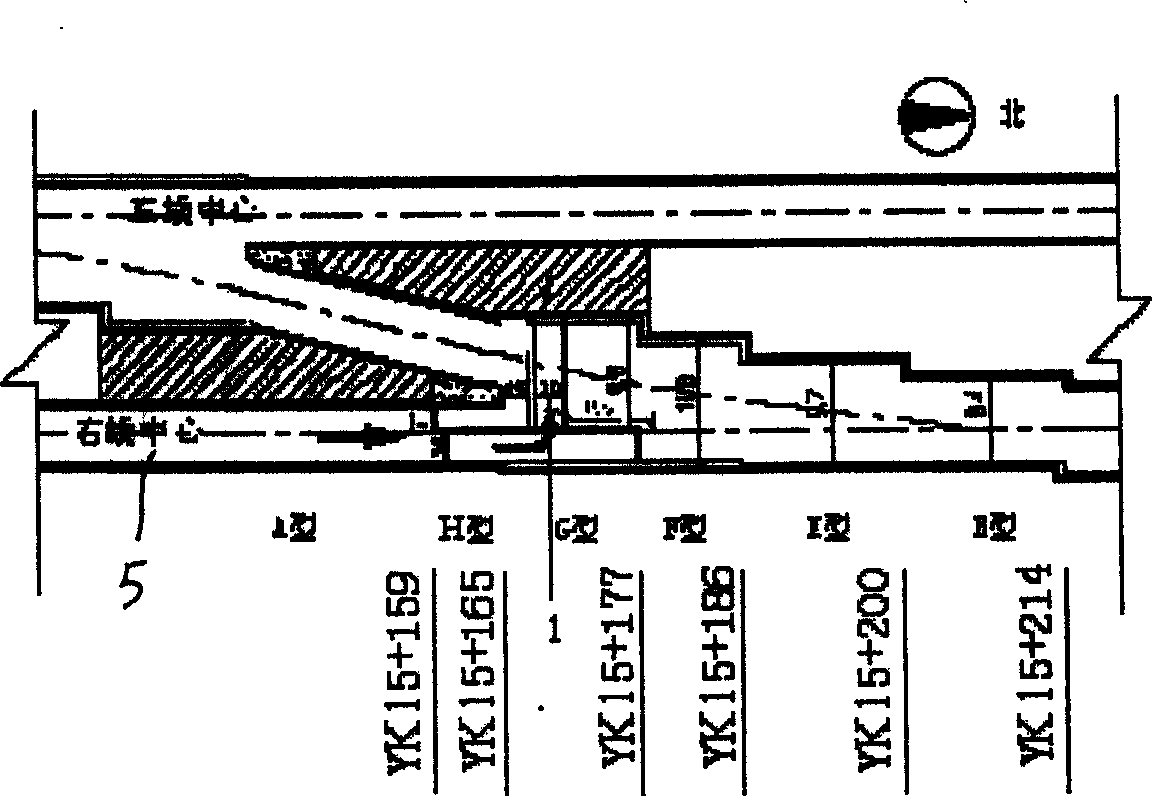

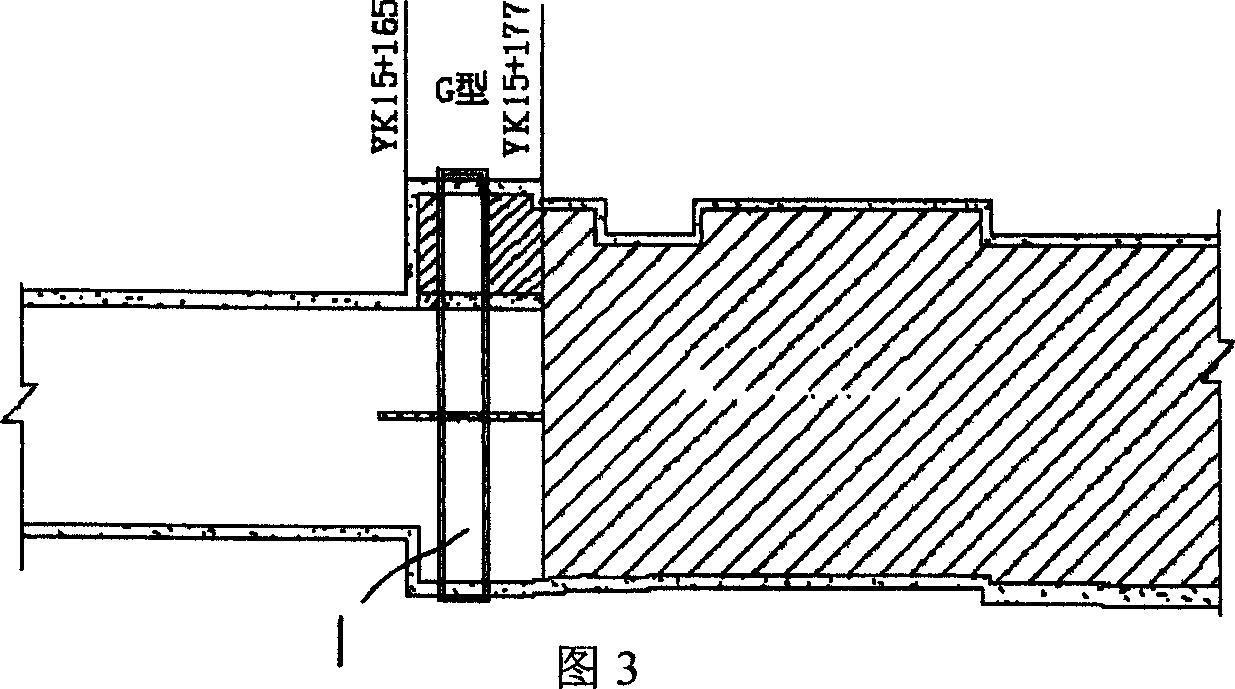

[0037] See figure 2 , Figure 3, the tunnel excavation, from the southern end of the A-type standard right-line tunnel to the turnout area after the large section of the working face is opened, the small right side pilot pit on the excavation face of the section continues to the north using the double-sided pilot pit Excavation of the upper and lower chambers on the right side of the G-section tunnel by the method, the construction stops at the sudden change of the other smaller F section in the front, forming a large-section right side wall pilot pit;

[0038] Then use the formed upper and lower side walls of the G-shaped section to open a lateral pilot pit 1 in the large section, so that the initial support of the entire G-shaped large section is included in the clearance of the lateral pilot pit 1, and proceed horizontally. Excavation and support up to the outermost edge of the excavation line on the left side of the G-shaped large section. After the formation of the lateral pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com