Manufacture method of sound box of imitating stone

A manufacturing method and speaker technology, applied to frequency/direction characteristic devices, transducer shells/cabinets/brackets, hollow objects, etc., can solve the problems of falling sound, easy to distort sound quality, easy sound leakage, etc., to improve sound quality and Good fidelity, sound quality and fidelity, not easy to crack and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

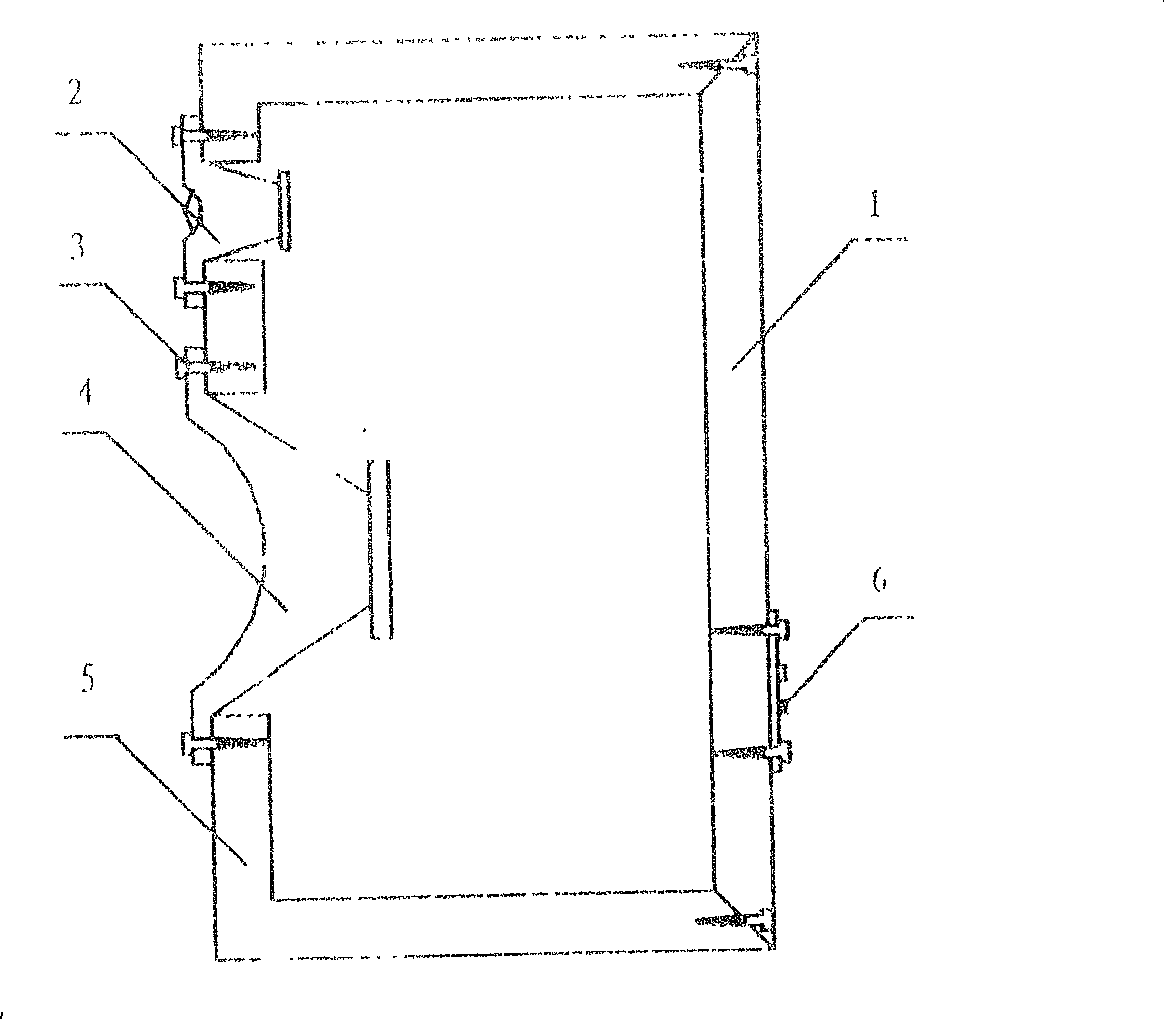

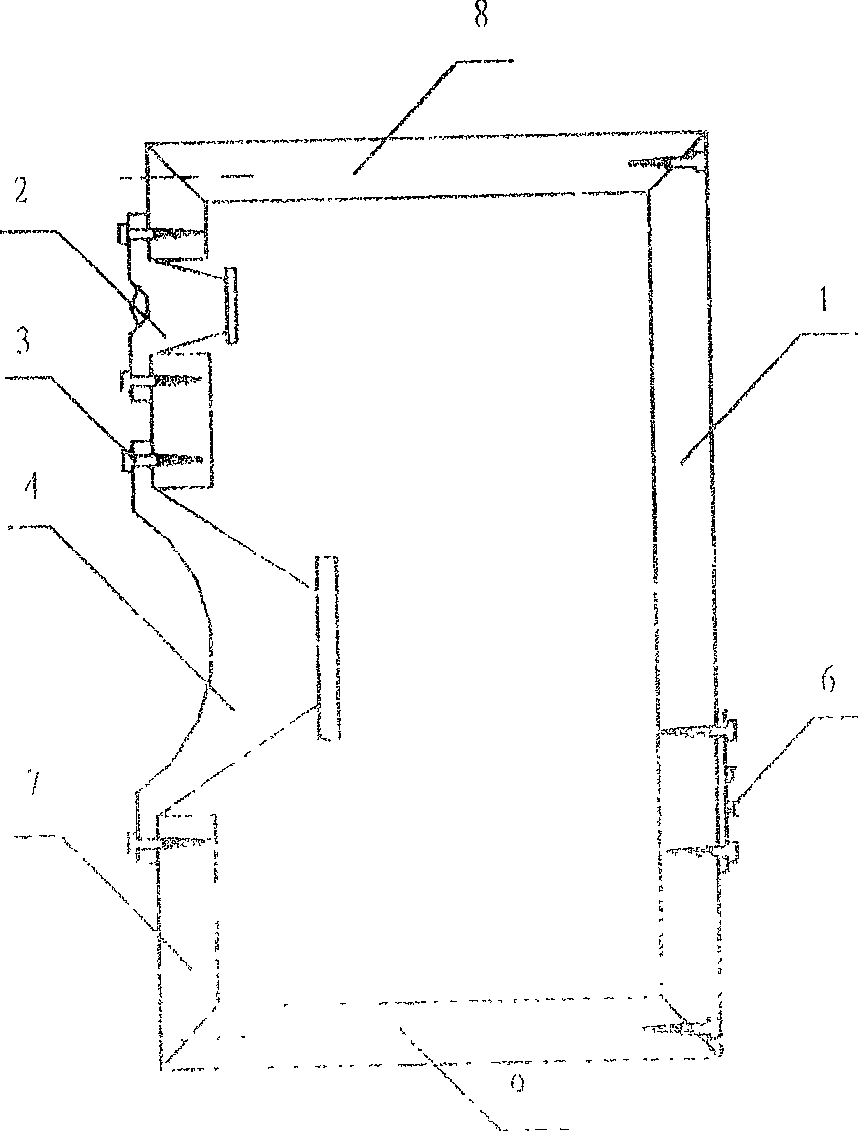

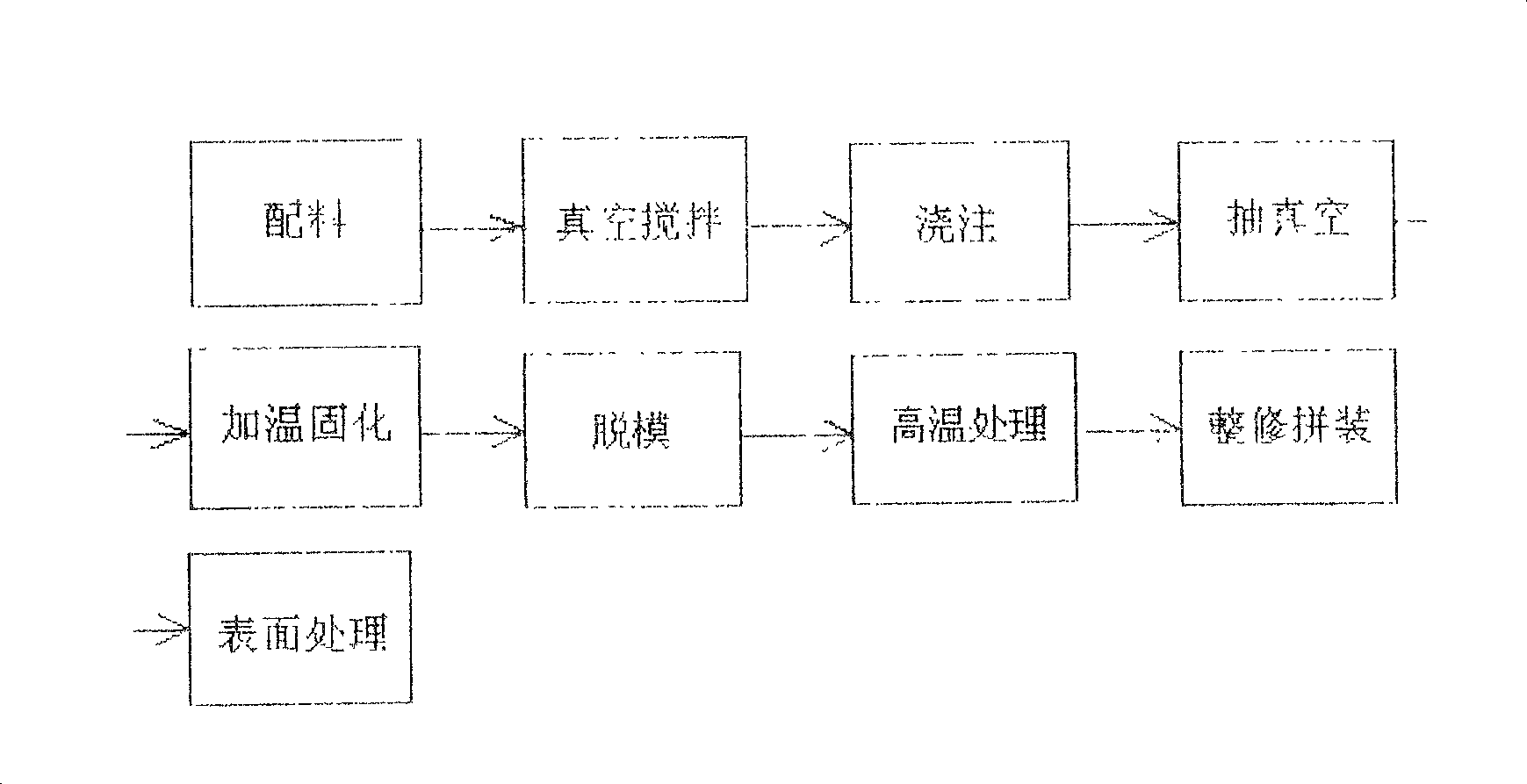

Embodiment 1

[0038] If 80 kg of raw materials are prepared to make box 5, the ingredients can be 32 kg of unsaturated polyester resin, 4 kg of polymer fiber, 42.4 kg of aluminum hydroxide powder, 0.4 kg of accelerator, 0.4 kg of curing agent, and 0.8 kg of defoamer ; Then put the prepared raw materials into the vacuum mixer and stir them fully; pour the stirred mixed raw materials into the box mold, pour and vibrate while pouring the materials; send the mold with the poured raw materials into the vacuum box along the track for vacuuming, vacuum The temperature should reach -0.1 MPa in the vacuum gauge, and the vacuuming time should be about 15 minutes; after the exhaust valve slowly releases the vacuum, send the mold along the track to the oven for heating, and the temperature should be kept at 60-85 temperature, the time should last about 10 minutes, and demould after curing; send the demoulded box 5 to the oven again for high-temperature treatment, and maintain a constant temperature of 8...

Embodiment 2

[0040]If 80 kg of colored raw materials with granules are prepared to make the panel of the speaker, the ingredients can be 32 kg of unsaturated polyester resin, 4 kg of polymer fiber, 8 kg of granules, 0.24 kg of color paste, 34.16 kg of aluminum hydroxide powder, accelerator 0.4 kg, 0.4 kg of curing agent, 0.8 kg of defoamer; then put the prepared raw materials into the vacuum mixer and fully stir; pour the stirred mixed raw materials into the tempered glass mold for making the panel, and level the raw materials; The mold is sent into the vacuum box along the track for vacuuming. The vacuum degree should reach -0.1 MPa in the vacuum gauge, and the vacuuming time needs to be about 15 minutes. The oven is heated, the temperature should be kept at about 60-85 degrees, and the time should last for about 10 minutes. After curing, demould; send the demoulded board to the oven again for high temperature treatment, and maintain a constant temperature of 85 degrees 2.5 hours; the pol...

Embodiment 3

[0043] If 80 kg of colored and luminous raw materials are prepared to make the panel of the speaker, the ingredients can be 32 kg of unsaturated polyester resin, 4 kg of polymer fiber, 0.24 kg of color paste, 0.4 kg of flash gold powder, 41.76 kg of aluminum hydroxide powder, and 0.4 kg of accelerator. kg, 0.4 kg of curing agent, and 0.8 kg of defoamer, and then proceed according to the above-mentioned process steps for making speaker panels. Due to the addition of gold glitter powder, the gold glitter powder will roll along with the vacuumed air bubbles, which can produce sparkling speaker panels with different texture patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com