Production method for extracting gallium

A product and filtrate technology, which is applied in the field of gallium metal extraction, can solve the problems of high cost and aluminum loss, and achieve the effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

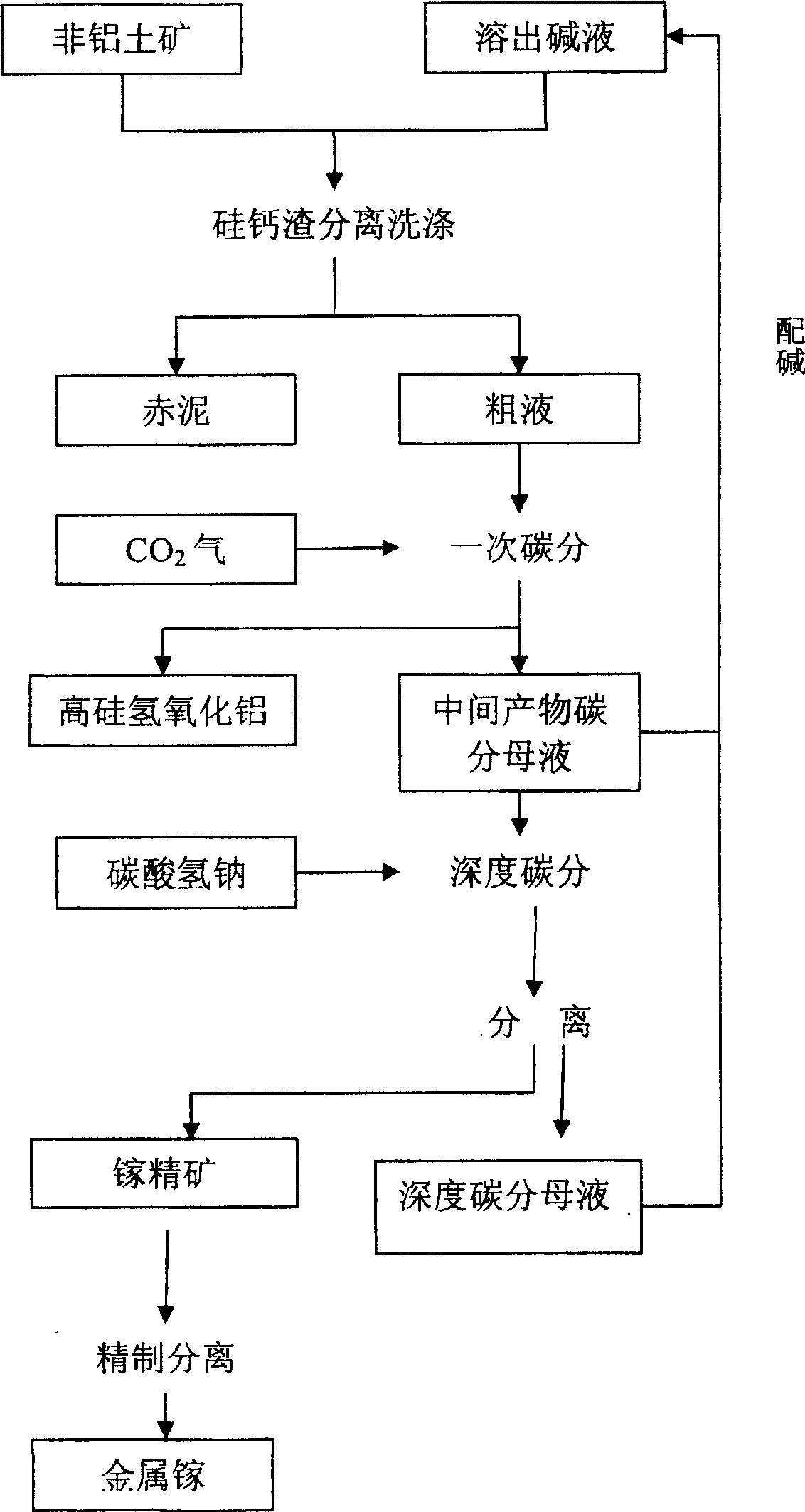

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: The present invention utilizes 1 ton of fly ash and 4 tons of limestone to prepare raw meal, sinters 3.1 tons of clinker at 1200°C, and dissolves the clinker with 60g / l sodium carbonate lye at a temperature of 70°C for 0.5 hours , liquid-solid separation to obtain silicon-calcium slag filter cake and sodium aluminum (gallium) acid (NaAl (Ga) O 2 ) filtrate 16.5m 3 . Among them, sodium aluminum (gallate) (NaAl (Ga) O 2 ) The concentration of aluminum oxide in the filtrate was 30 g / l, and the concentration of gallium oxide was 0.067 g / l. Sodium aluminum (gallium) filtrate adopts CO 2 Continuous carbonation and decomposition to obtain aluminum hydroxide filter cake and intermediate product carbon separation mother liquor filtrate 16.3m 3 . Determination of the aluminum oxide concentration in the intermediate product carbon fraction mother liquor filtrate is 0.64g / l, and when the concentration of gallium oxide is 0.064g / l, take the carbon fraction mother ...

Embodiment 2

[0010] Embodiment 2: The present invention utilizes 0.7 tons of fly ash, 0.3 tons of coal gangue, and 1.5 tons of limestone to prepare raw meal, and sinters 1.6 tons of clinker at 1450° C., and the clinker uses 60 g / l of sodium carbonate lye at a temperature of 70° C. After 1 hour of stripping at high temperature, the liquid-solid separation obtains calcium-silicon slag filter cake and sodium aluminum (gallium) acid (NaAl (Ga) O 2 ) filtrate 3.7m 3 . Among them, sodium aluminum (gallate) (NaAl (Ga) O 2 ) The concentration of aluminum oxide in the filtrate was 40 g / l, and the concentration of gallium oxide was 0.06 g / l. Sodium aluminum (gallium) filtrate adopts CO 2 Continuous carbonation and decomposition to obtain aluminum hydroxide filter cake and intermediate product carbon separation mother liquor filtrate 2.6m 3 . Measure the aluminum oxide concentration in the intermediate product carbon fraction mother liquor filtrate 1.42g / l, and when the concentration of gallium ...

Embodiment 3

[0011] Embodiment 3: The present invention utilizes 0.6 tons of fly ash, 0.2 tons of coal gangue, 0.2 tons of kaolin and 2 tons of limestone to prepare raw meal, and sinters 1.9 tons of clinker at 1350 ° C, and uses 60 g / l sodium carbonate lye for clinker After leaching for 1 hour at a temperature of 70°C, the liquid-solid separation obtained calcium-silicon slag filter cake and sodium aluminum (gallium) acid (NaAl (Ga) O 2 ) filtrate 6.3m 3 . Among them, sodium aluminum (gallate) (NaAl (Ga) O 2 ) The concentration of aluminum oxide in the filtrate was 26 g / l, and the concentration of gallium oxide was 0.05 g / l. Sodium aluminum (gallium) filtrate adopts CO 2 Continuous carbonation and decomposition to obtain aluminum hydroxide filter cake and intermediate product carbon separation mother liquor filtrate 6.2m 3 . When the concentration of aluminum oxide in the intermediate product carbon fraction mother liquor filtrate is 2.0g / l, and the concentration of gallium oxide is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com