Gas compressor load discharging valve

A gas compressor and unloading valve technology, applied in the field of gas compressors, can solve the problems of poor unloading valve performance, unstable cylinder action, thick main spring, etc., to reduce load and weight, easy assembly and debugging, and vibration. and less jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The gas compressor unloading valve of the present invention will be described in further detail below in conjunction with the accompanying drawings.

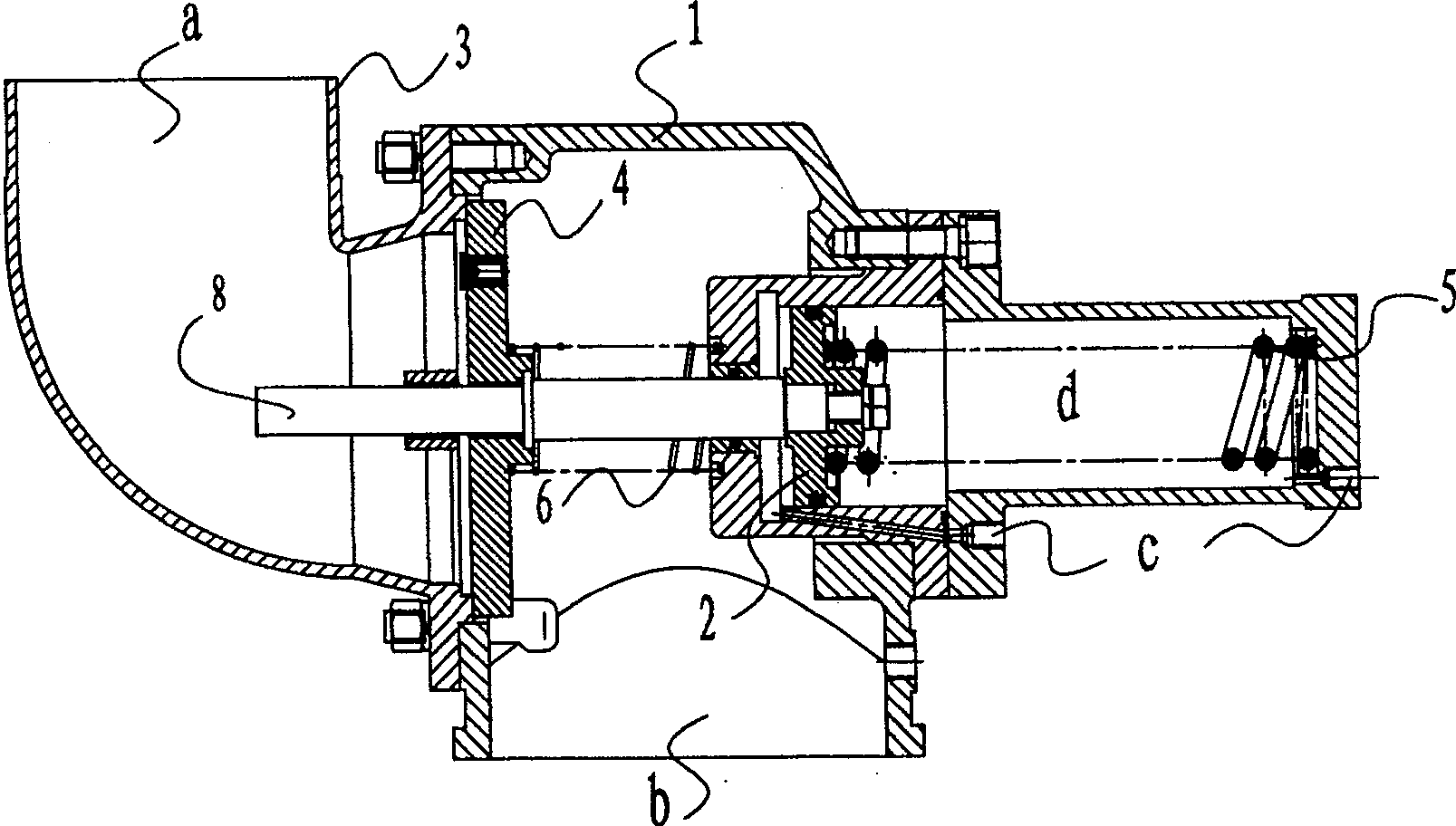

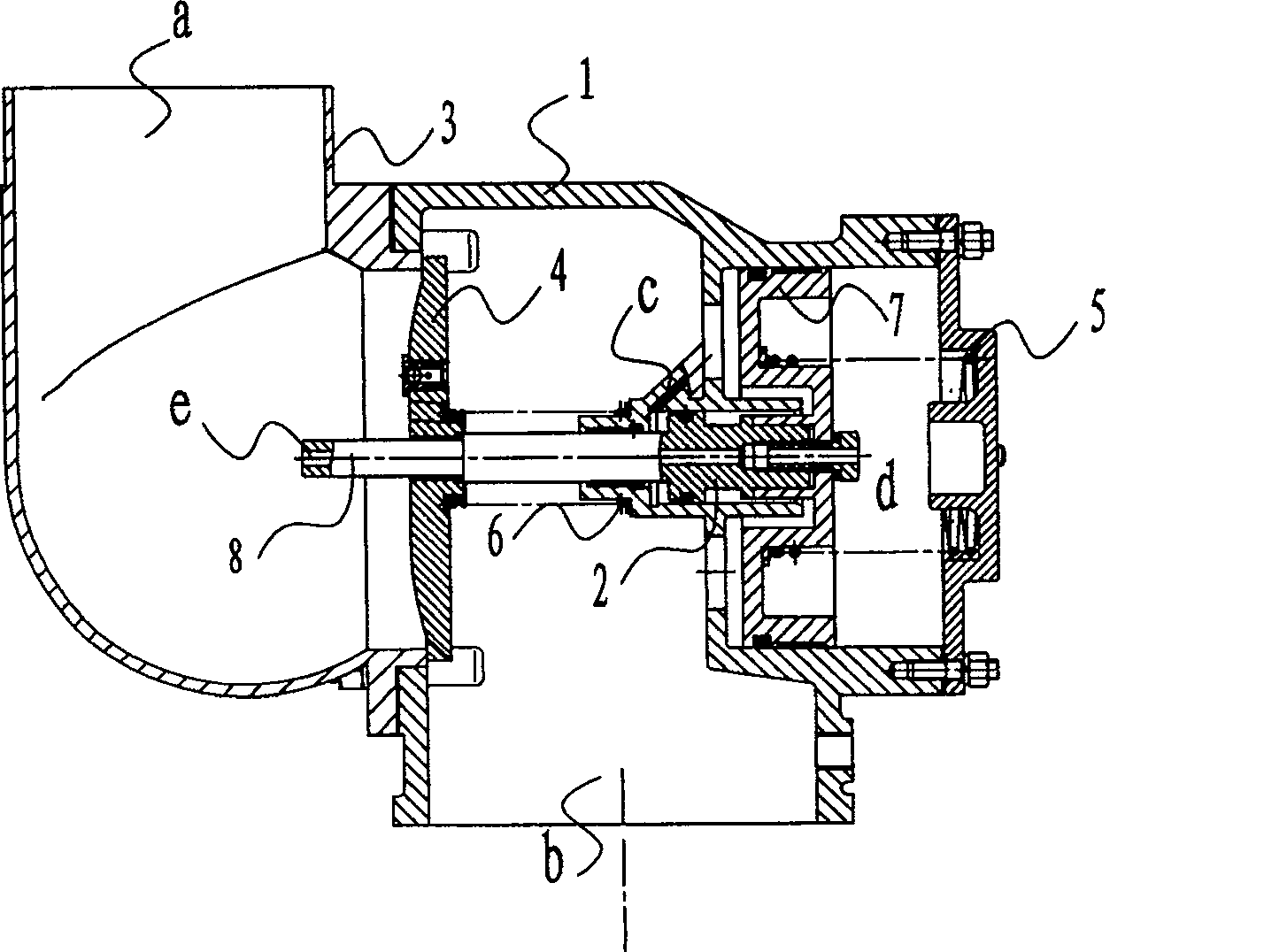

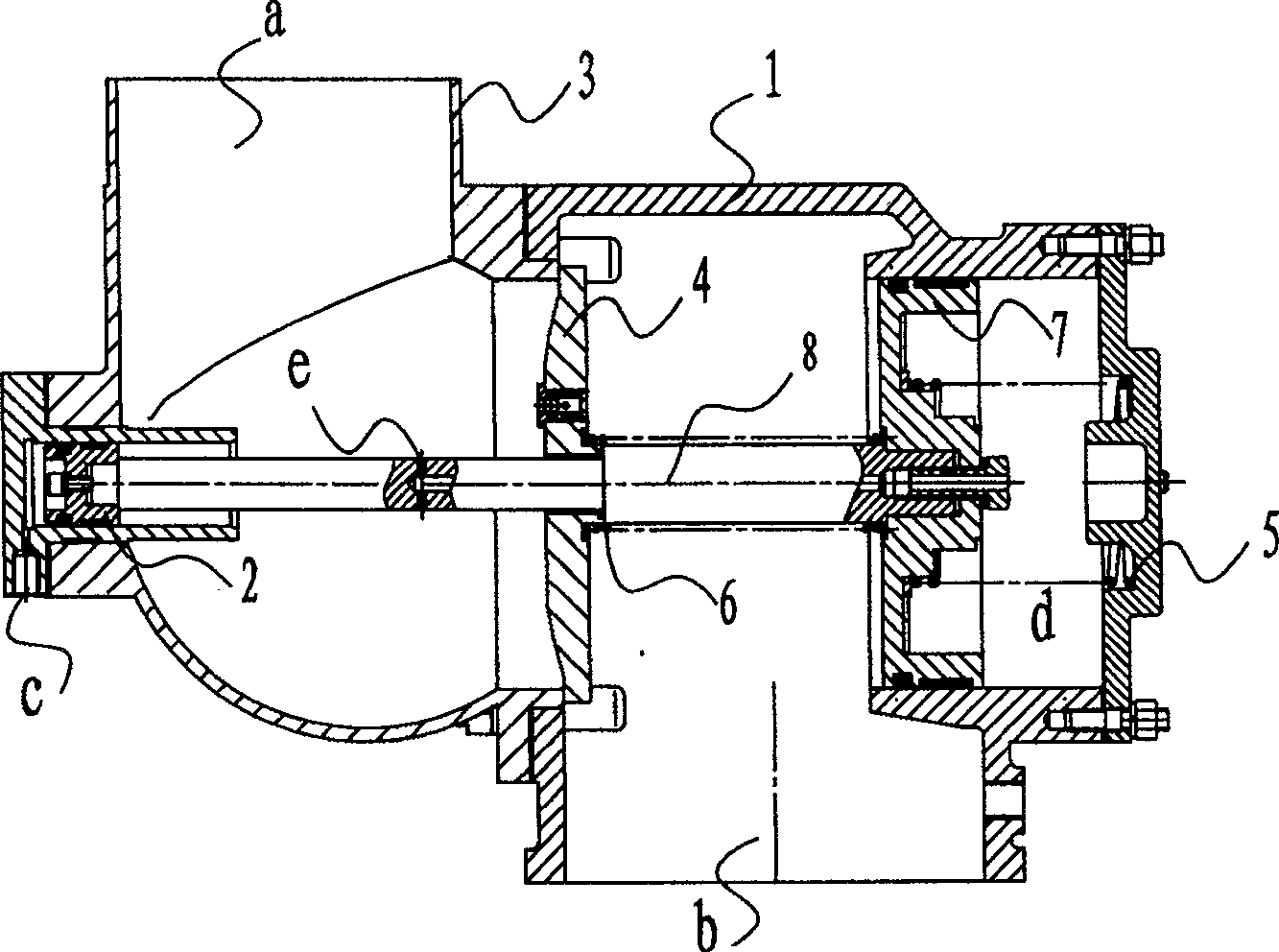

[0022] Such as figure 2 As shown, the gas compressor unloading valve described in Embodiment (1) of the present invention is mainly composed of valve body 1, power piston 2, air guide pipe 3, valve plate 4, main spring 5, small spring 6, balance piston 7, piston Composed of a rod 8, the valve is provided with an air guide channel a, an intake channel b, a control air channel c and a balance chamber d. The valve plate 4 is connected to the power piston 2 through the piston rod 8, the balance piston 7 is installed on the right end of the power piston 2 (can have various positions), the balance piston 7 is located in the balance chamber d and can be left and right in the balance chamber d slide. The small spring 6 is looped on the piston rod 8, and its two ends press against the valve plate 4 and the valve body 1 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com