Overflow valve for excavator main control valve with filter device

A filter device and main control valve technology, which is applied in the field of hydraulic devices to achieve the effects of good opening and closing characteristics, compact structure and stable internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

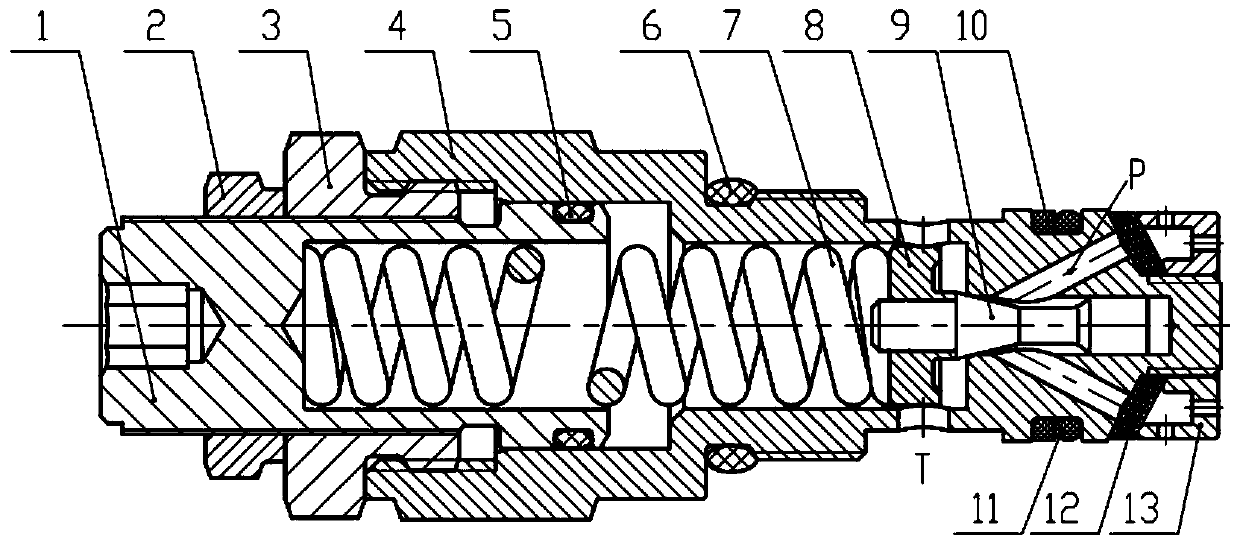

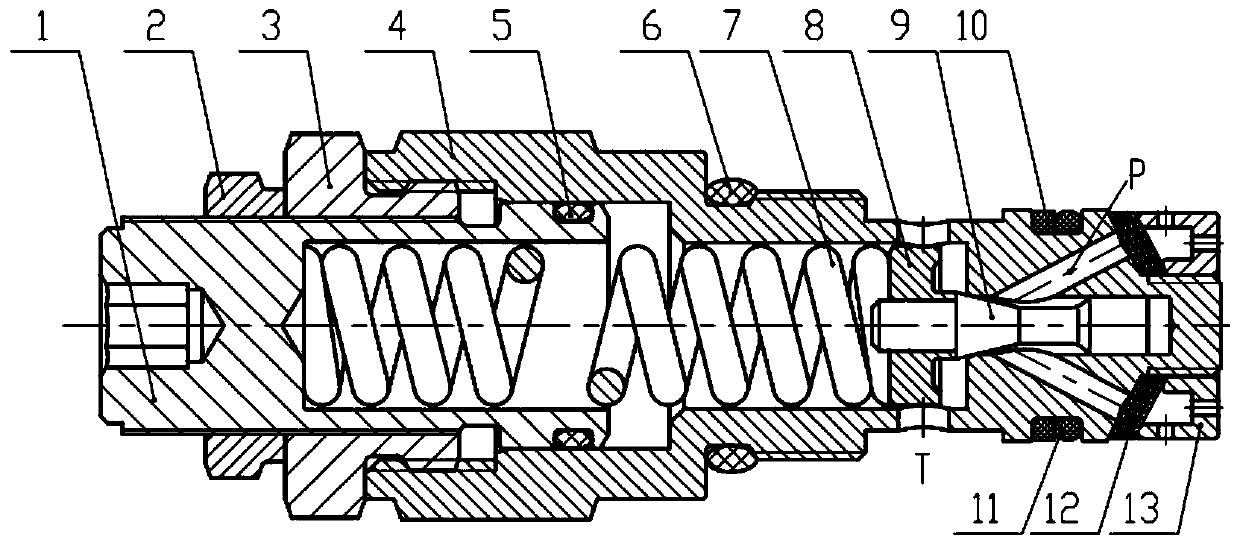

[0018] The present invention is an overflow valve for a main control valve of an excavator with a filtering device, such as figure 1 As shown, it includes a control spool 9, the control spool 9 is arranged at the front end of the inner cavity of the valve seat 4, the front end of the control spool 9 is matched with the inner cavity of the valve seat 4, and the hydraulic oil enters the control spool 9 from the matching gap to the end. The front end opens the control spool 9 after reaching the set pressure. Spring seat 8 is contained on the rear end of control spool 9, and spring force is applied on the control spool 9, and control spool 9 is closed state under normal state, and it forms line seal with valve seat 4. One end of the spring 7 withstands the rear end of the control valve core 9 through the spring seat 8, and the other end of the spring 7 withstands the front end of the adjusting bolt 1, that is, one end of the spring 7 is connected to the spring seat 8, and the othe...

Embodiment 2

[0025] In this embodiment, the valve seat 4 is provided with 4 oblique oil inlet holes P and 4 oil return inner holes T. Each inclined oil inlet P is connected with a small hole on a filter seat 13 through a filter screen 12 . Between the valve seat 4 and the filter seat 13, four layers of 60-mesh filter screens 12 are arranged. The filtering accuracy of the filter screens 12 is 25 μm, and the total thickness of all the filter screens 12 is 1.6 mm.

[0026] Others are the same as in Example 1.

Embodiment 3

[0028] In this embodiment, two layers of 60-mesh filter screens 12 are arranged between the valve seat 4 and the filter seat 13. The filtering accuracy of the filter screens 12 is 20 μm, and the total thickness of all the filter screens 12 is 0.8 mm.

[0029] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com