Method and system for regulating torque transmission capacity of torque transmitting assembly

A technology of torque transmission and components, applied in the direction of transmission, components with teeth, transmission control, etc., can solve problems such as difficulty in correlation calculation, and achieve the effect of simplifying analysis and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

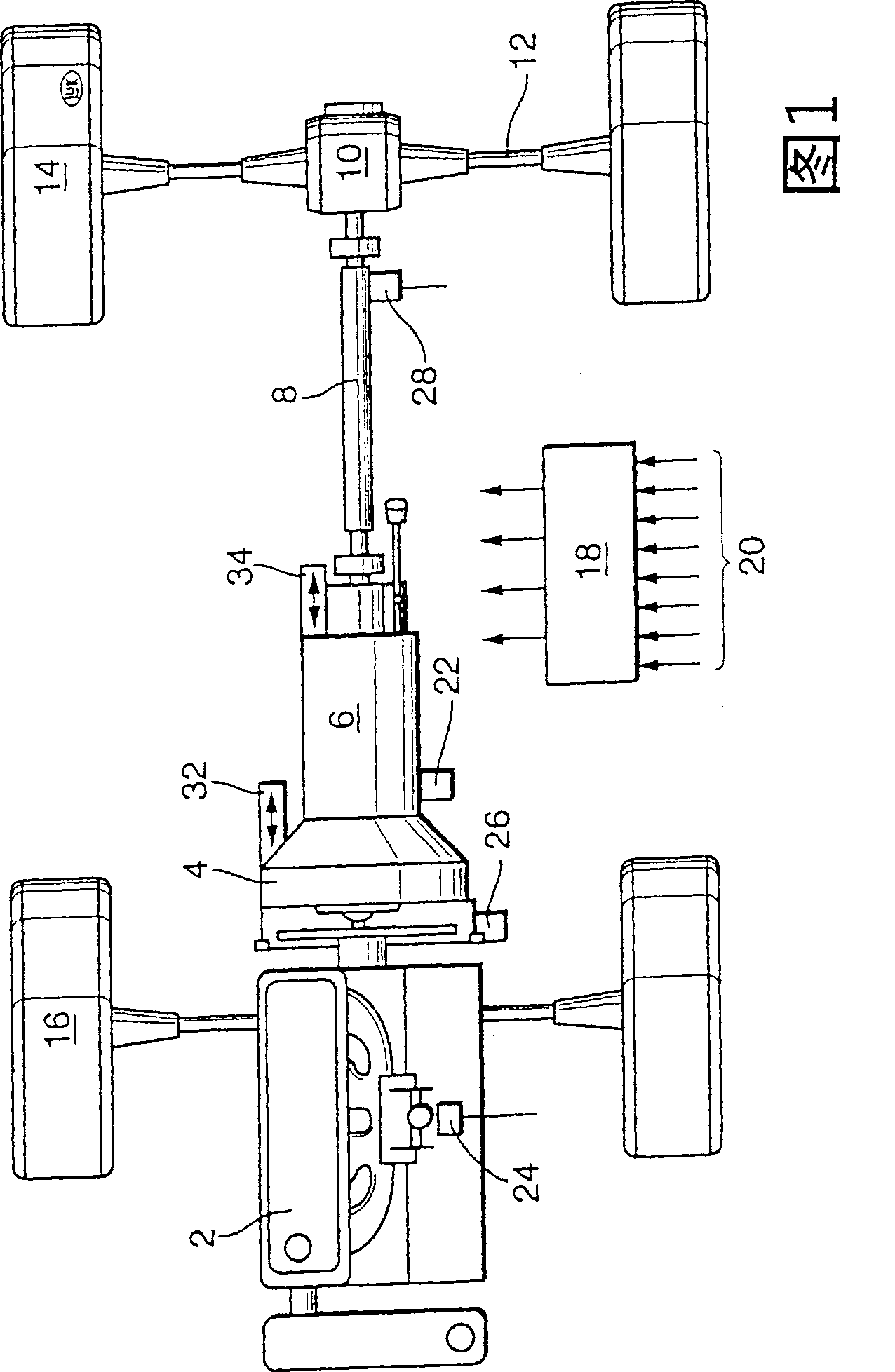

[0032] According to FIG. 1, the motor vehicle has an engine 2 which is connected to a cardan shaft 8 via a clutch 4 and a transmission 6. The cardan shaft 8 drives each half shaft 12 through a differential 10, and these half shafts are connected to the rear wheels 14 without relative rotation. In the illustrated example, the front wheels are not driven.

[0033] An electronic control device 18 comprising a microprocessor with an attached storage device in a known manner has input terminals 20 which are connected to sensors. Examples of sensors include: a sensor 22 for detecting the speed of the transmission input shaft, a throttle sensor 24, an engine speed sensor 26, a cardan shaft speed sensor 28 and possibly other sensors.

[0034] The output end of the control device 18 is connected to the clutch operating device 32 and the transmission operating device 34, and when necessary, to other actuators of the drive train, such as a throttle valve regulator.

[0035] In the illustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com