Resin membrane forming method and apparatus thereof

A technology of resin film and resin, which is applied to the device for coating liquid on the surface, pre-treatment surface, coating, etc., can solve the problems of pores, unsightly appearance, etc., and achieve the prevention of poor contact, high-precision heating, stable quality, The effect of improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

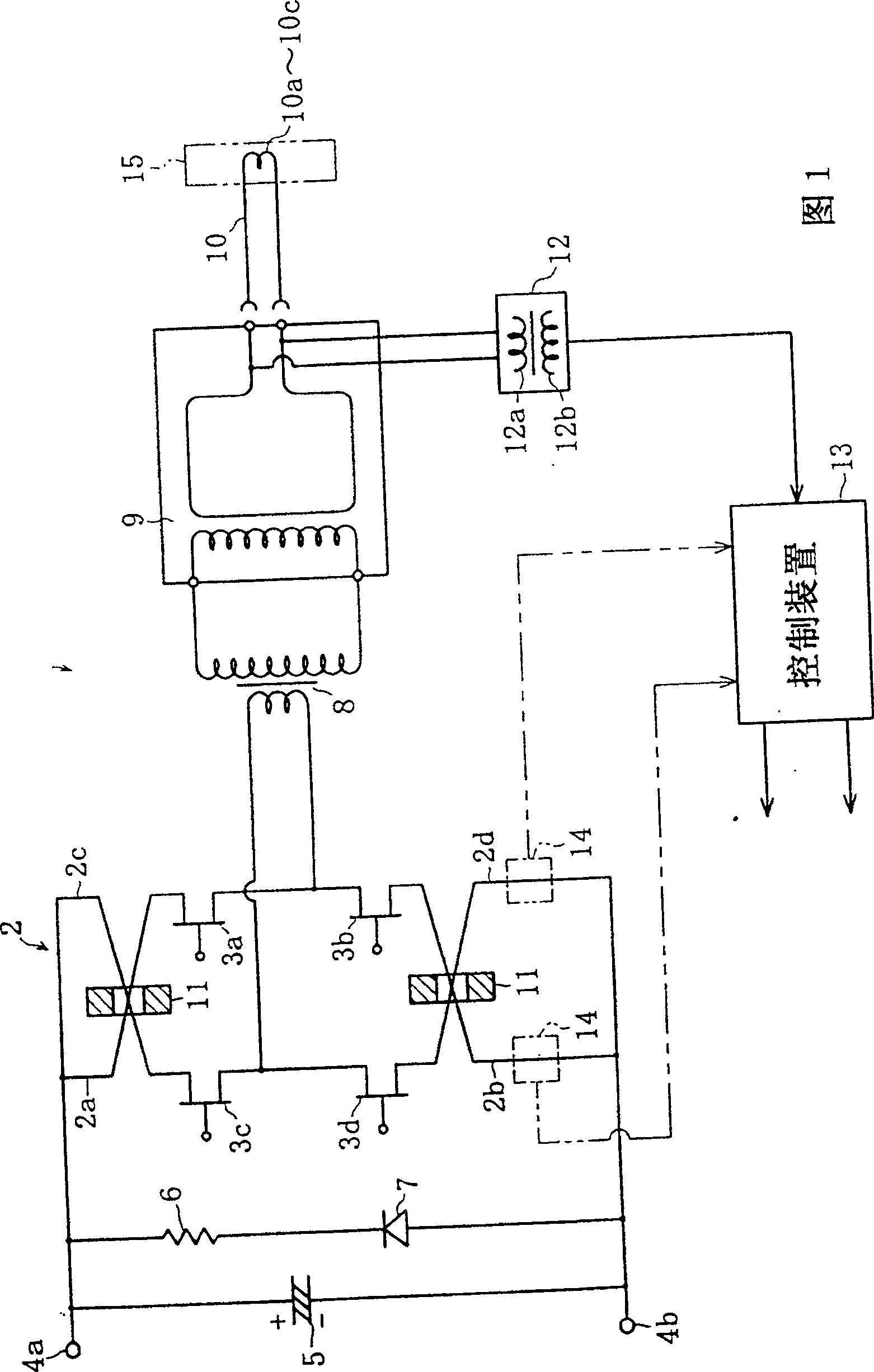

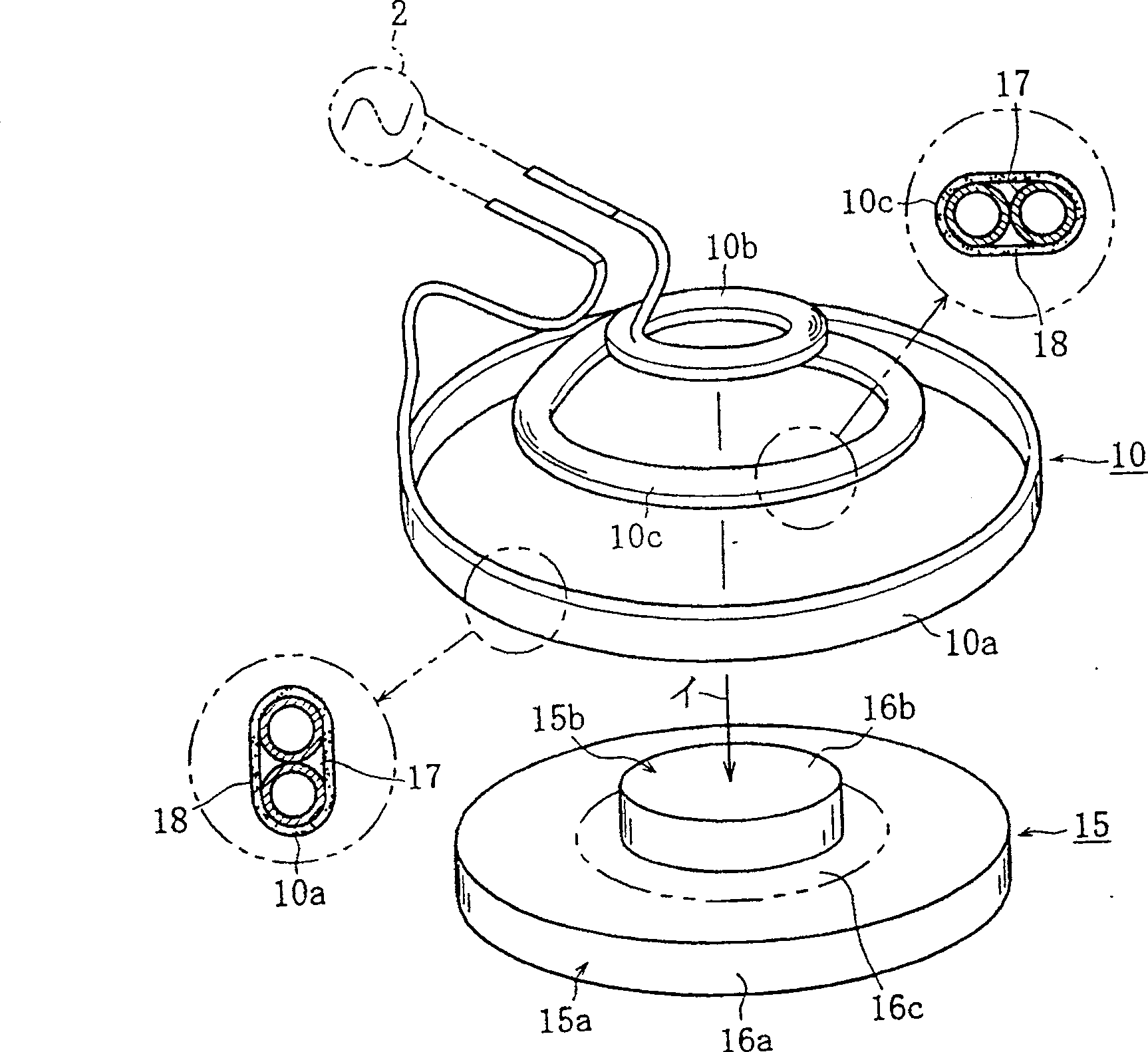

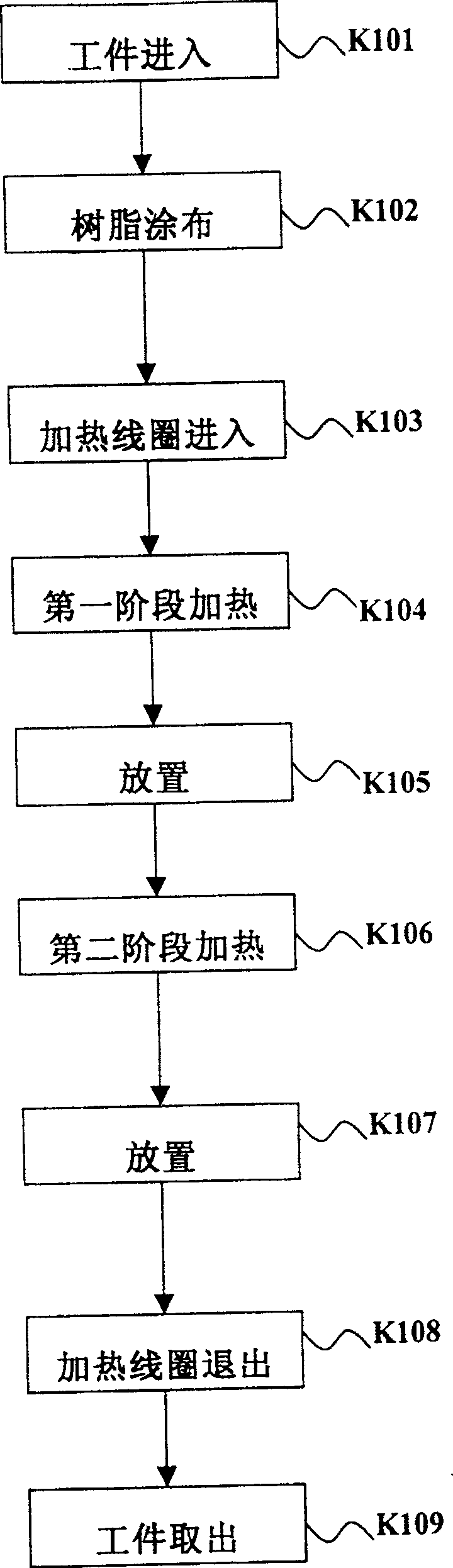

[0031] figure 1- Figure 4 It is an embodiment of the resin film forming method and apparatus of the present invention.

[0032] In FIG. 1, a resin film forming apparatus 1 has a transistor-type frequency conversion circuit 2, and four branches 2a-2d of the frequency conversion circuit 2 are respectively connected to four semiconductor switching elements FET3a-3d. And, among the branches 2a-2d of the frequency conversion circuit 2, the branch 2a and the branch 2b are connected in series, and the branch 2c and the branch 2d are connected in series. At the same time, since the connection point of branch 2a and branch 2c is connected to DC power supply + terminal 4a, and the connection point of branch circuit 2b and branch circuit 2d is connected to DC power supply - terminal 4b, a complete bridge circuit is formed. Furthermore, between the above-mentioned terminals 4a and 4b, an electrolytic capacitor 5 and a resistor 6 and a diode 7 connected in series are connected.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com