Vapor double-heating pressure vapor iron

A pressurized steam and double heating technology, which is applied in hand irons, washing devices, textiles and papermaking, etc., can solve problems such as water leakage on the soleplate, low steam intensity, and affecting the effect of ironing, so as to prevent overheating of the soleplate and overcome pressure steam. Continuity, the effect of improving the quality of ironing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate the present invention below in conjunction with accompanying drawing.

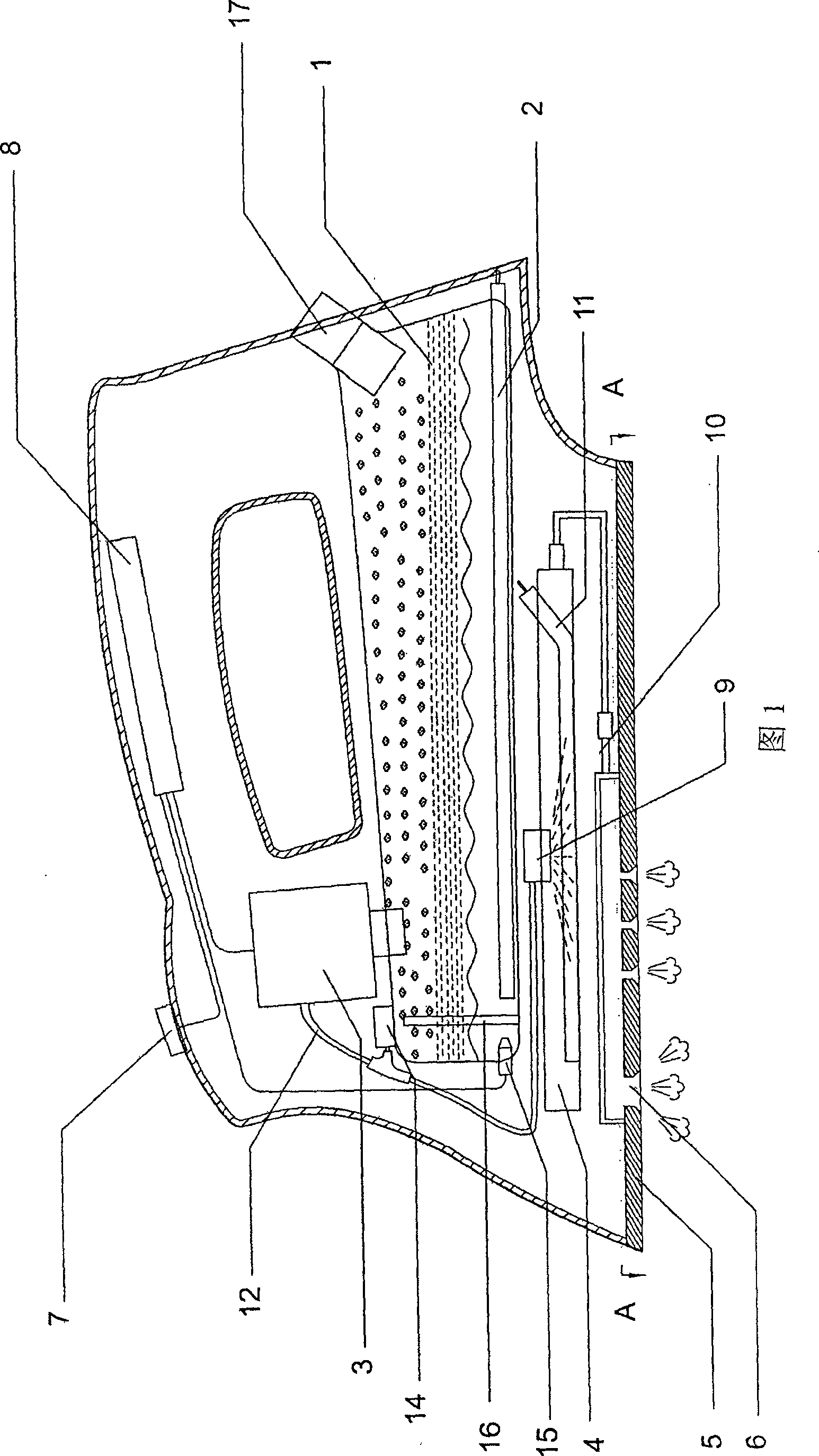

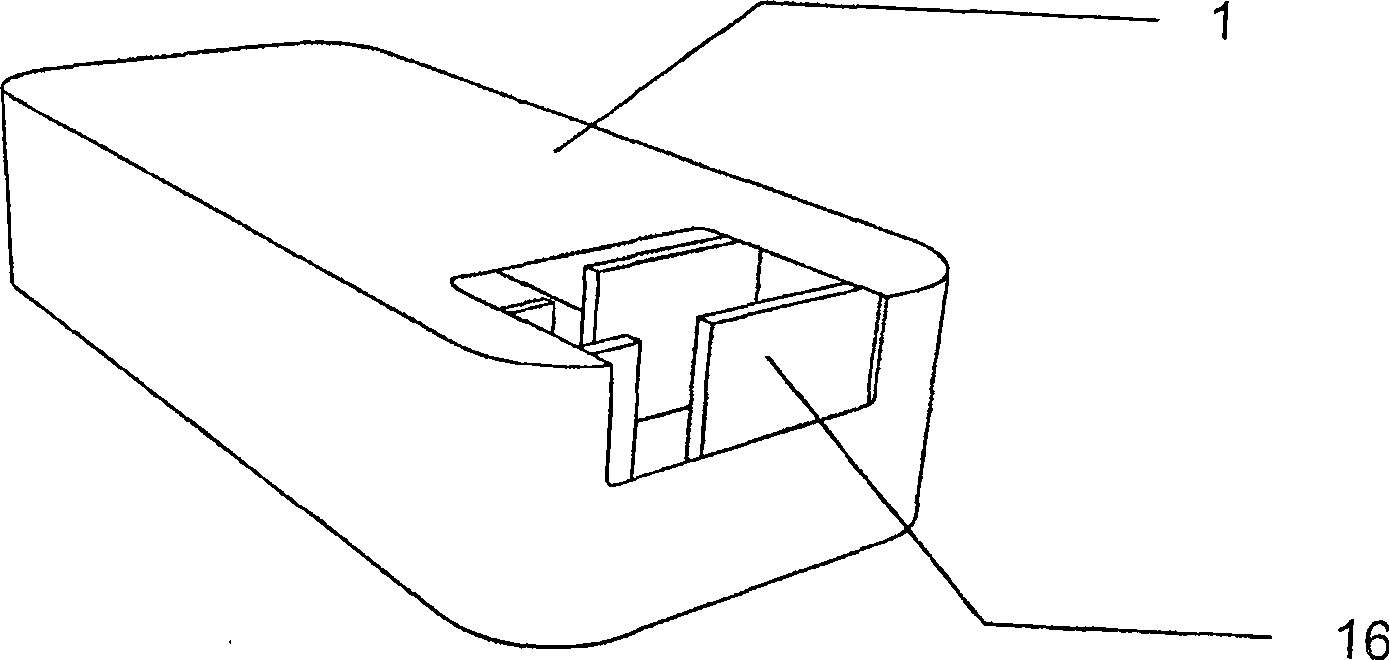

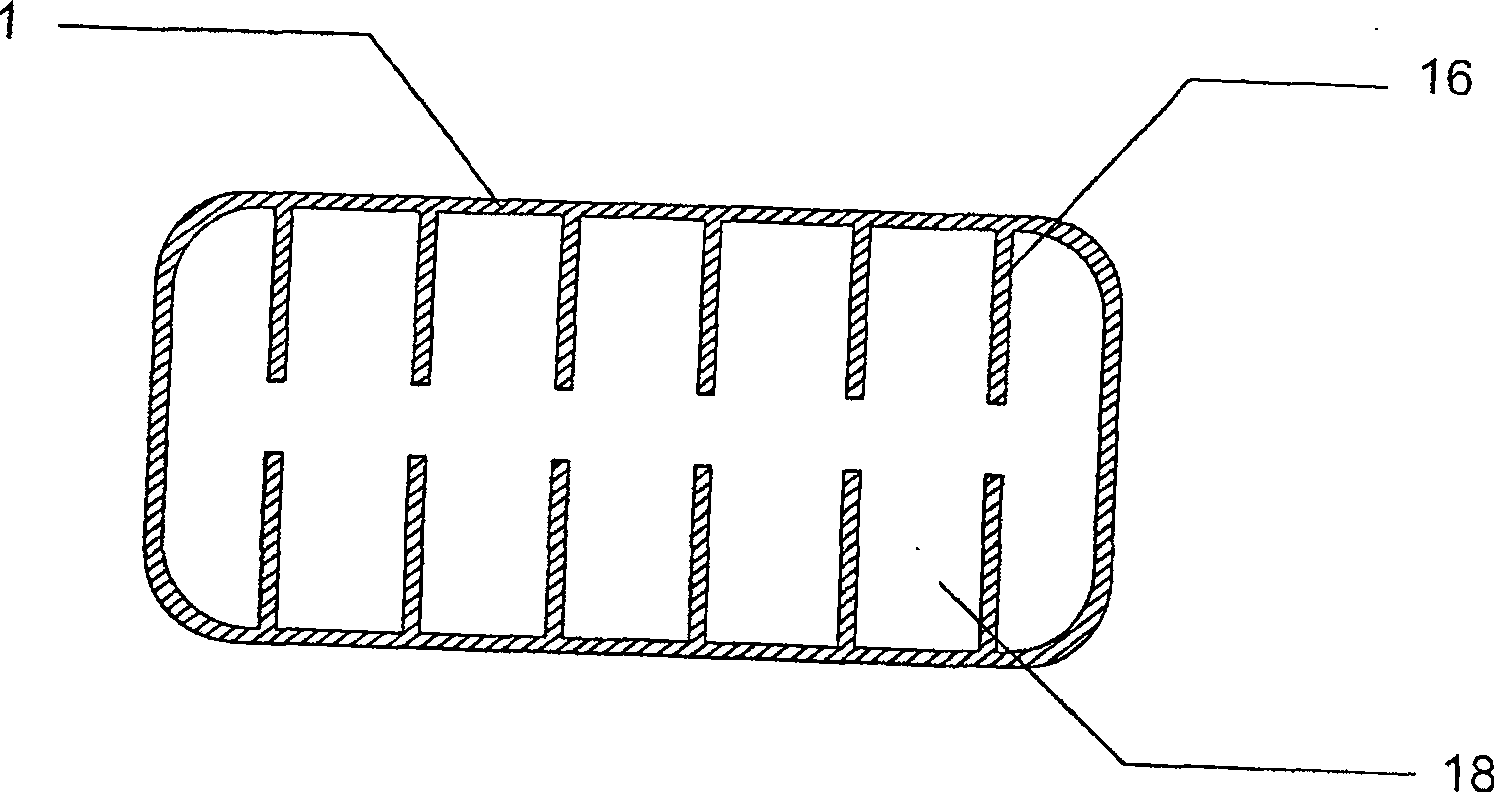

[0014] Referring to Fig. 1, the water-air double heating pressure steam iron of the present invention comprises a water heating container 1 equipped with a heating tube 2, a bottom plate 5 with an exhaust hole 6, an operation control button 7 and a circuit board 8 installed on the handle and Gas heating chamber 4. In the legend, the air heating chamber 4 is located between the water heating container 1 and the bottom plate 5, and is a sealed flat rectangular chamber. The top surface of the air heating chamber 4 is threaded and installed with an atomizing nozzle 9, and a heating device is installed in the chamber. Tube 11. A two-position two-way direct-acting solenoid valve 3 is installed on the water heating container 1. One end of the solenoid valve 3 communicates with the water heating container 1, and the other end communicates with the atomizing nozzle 9 on the gas heating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com