Pressure-accumulating jet system

A technology of injection system and pressure accumulation, applied in charging system, fuel injection device, fuel injection control, etc., can solve problems such as low fuel injection correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

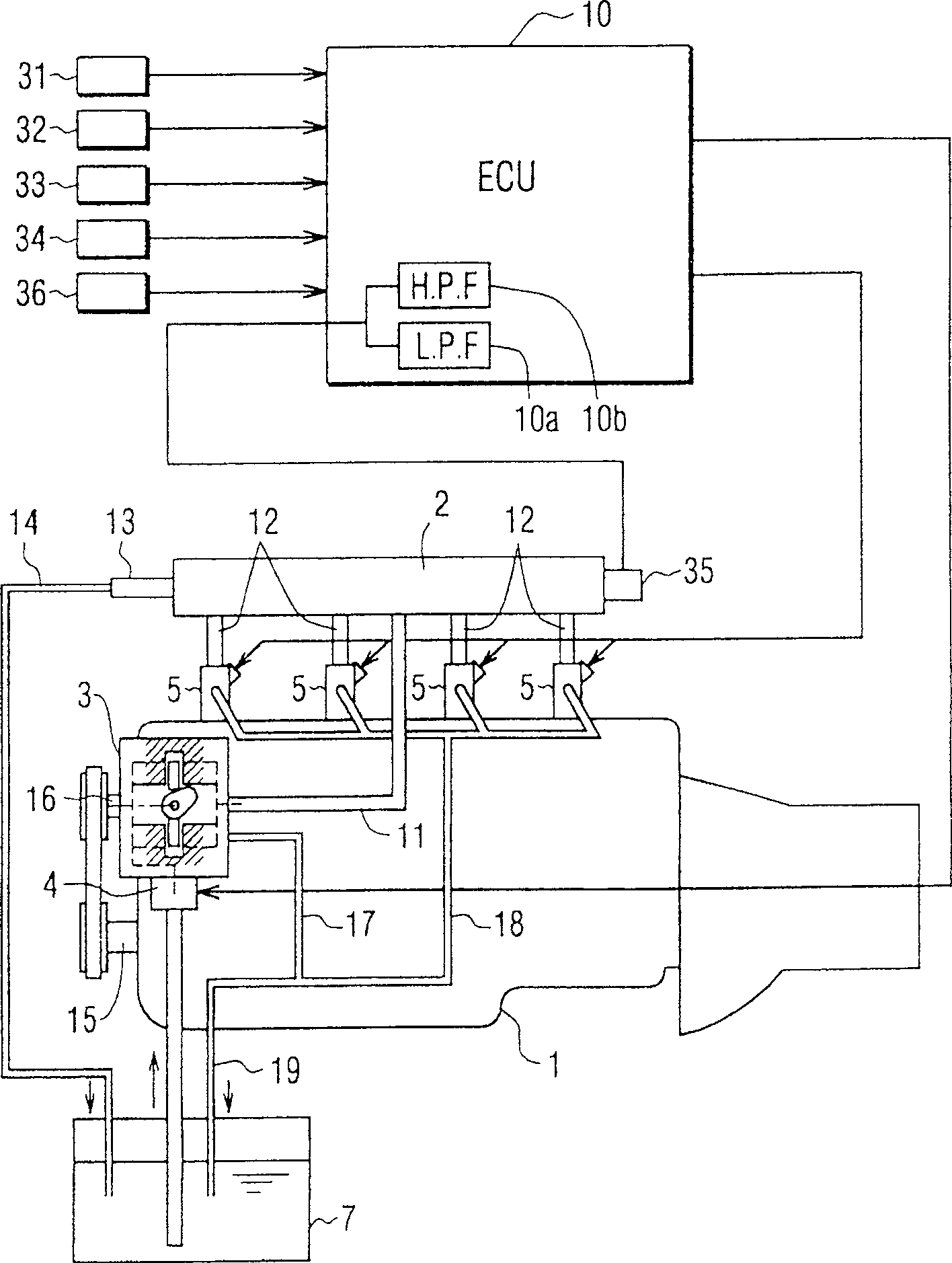

[0064] figure 1 ~4 shows a first embodiment of the invention, figure 1 is a block diagram showing a common rail fuel injection system.

[0065] A common rail fuel injection system is used on engines such as 4 cylinder diesel engines. The common rail fuel injection system includes a common rail 2 used as an accumulator, in which high-pressure fuel is accumulated to a pressure that is the same as a fuel injection pressure capable of injecting fuel into each cylinder. The common rail fuel injection system also has a fuel supply pump 3 for applying pressure to the absorbed fuel and then pumping the pressurized fuel into the common rail 2 . The common rail fuel injection system also has a plurality of electromagnetic fuel injection valves 5 for supplying high-pressure fuel stored in the common rail 2 into the cylinders of the engine 1 . Typically the engine 1 has 4 cylinders. The electromagnetic fuel injection valve 5 is hereinafter referred to as a nozzle. The common rail fue...

no. 2 example

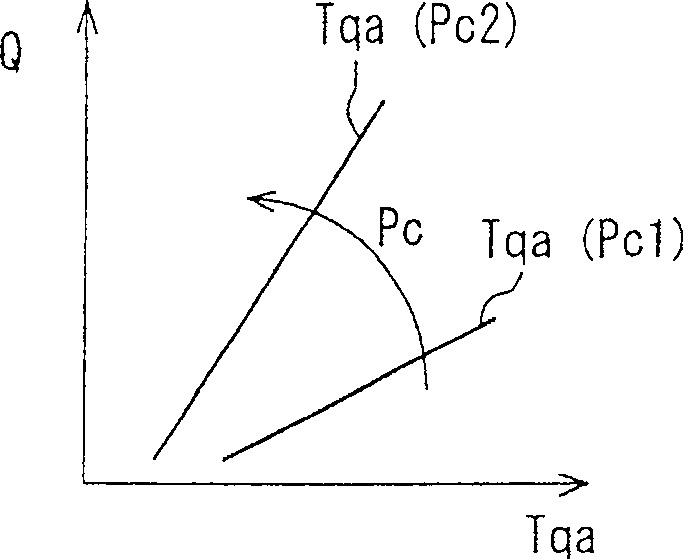

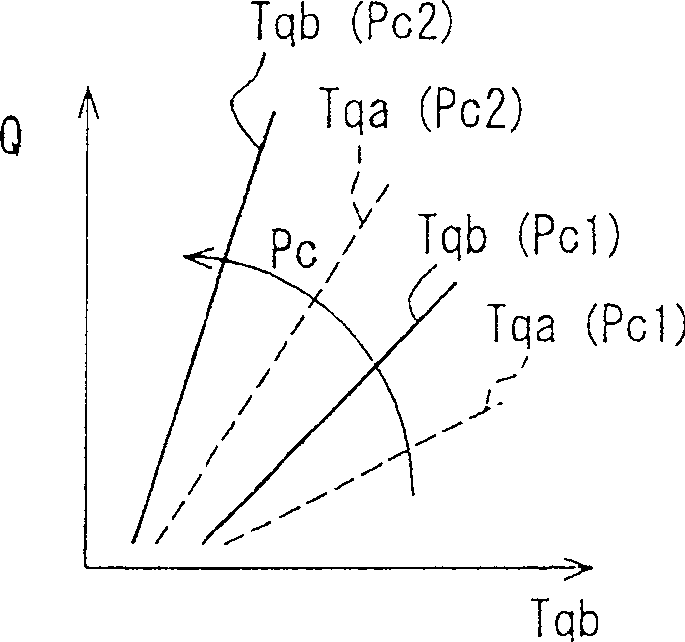

[0094] In the second embodiment, only one basic feature map is used. The basic characteristic map is used to find the first basic fuel injection duration Tqa for non-overlapping cylinders. Based on the actual time overlapping portion t, the first basic fuel injection duration Tqa is corrected to determine the second basic fuel injection duration Tqb of the overlapping cylinders.

[0095] More specifically, using a correction means for correcting the first basic fuel injection duration Tqa of non-overlapping cylinders, changing the first basic fuel injection duration Tqa and the second basic fuel injection duration Tqb of overlapping cylinders difference between, or using a correction means for correcting the second basic fuel injection duration Tqb, change the difference between the second basic fuel injection duration Tqb and the first basic fuel injection duration Tqa, thereby The second basic fuel injection duration Tqb is made shorter than the first basic fuel injection d...

no. 3 example

[0105] Figure 8-12 A third embodiment of the invention is shown, in which Figure 8 A flowchart showing a method of controlling fuel injection using a fuel injection valve. on the other hand, Figure 9 A flowchart of a method of finding temporal overlaps is shown. exist Figure 8 with 9 The routine represented by the flow chart shown in is repeatedly executed at a predetermined timing after the ignition switch is turned on.

[0106] Figure 8 The flow chart shown starts at step S31, where engine parameters are input. The engine parameters include engine speed NE and accelerator on ACCP. Then in step S32, the target fuel injection quantity Q is determined based on the engine speed NE and the acceleration-on ACCP. Then at step S33, the target fuel injection timing T is determined based on the engine speed NE and the accelerator-on ACCP. Then in step S34, the common rail fuel pressure Pc is input.

[0107] Then at step S35, the target fuel injection timing T is convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com