Double acting type repulsive differential driven power system of electrical motor group

A power system and differential drive technology, which is applied in the control system, motor speed or torque control, electrical components, etc., can solve the problems of high cost, heavy weight, and normal transmission loss of differential transmission devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

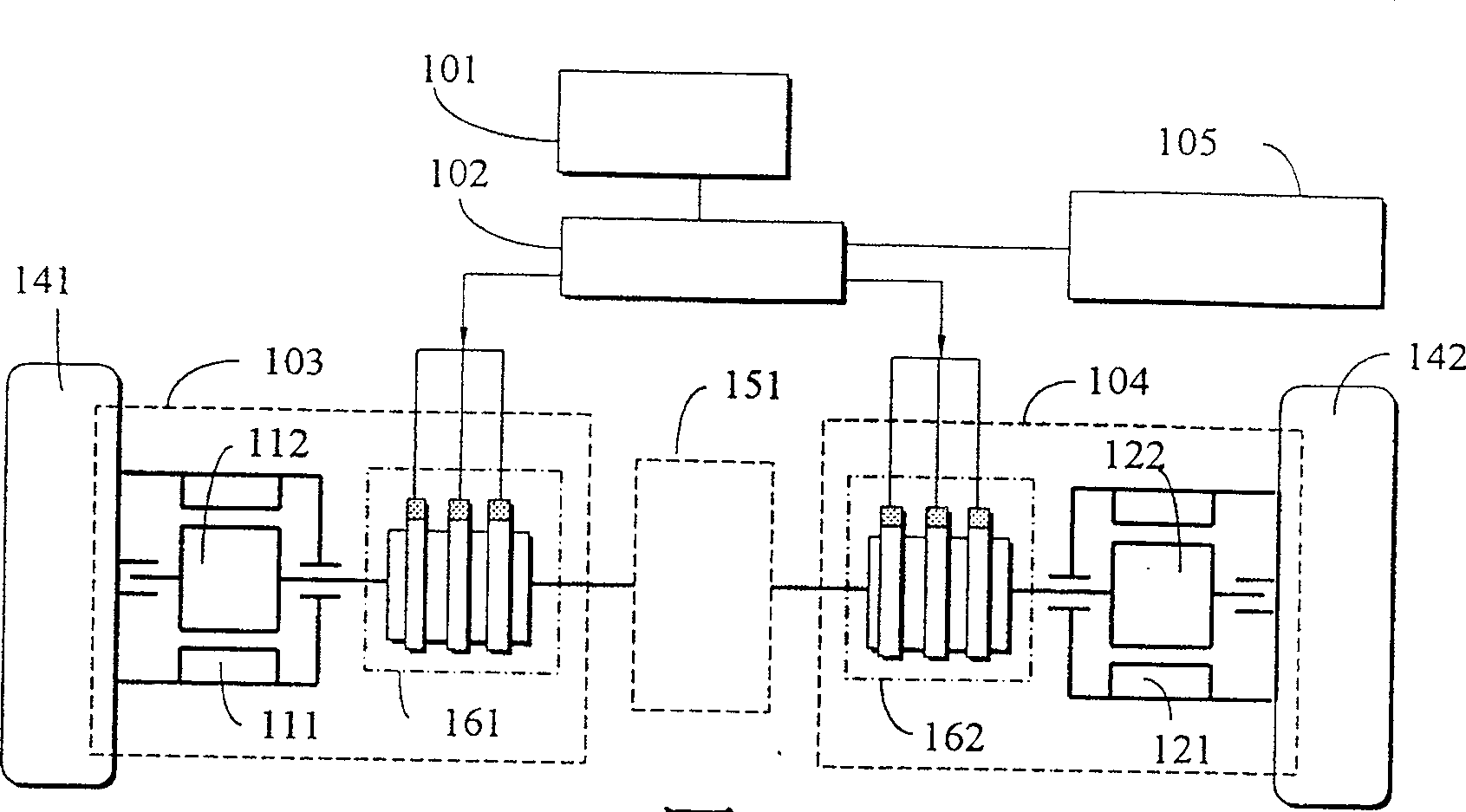

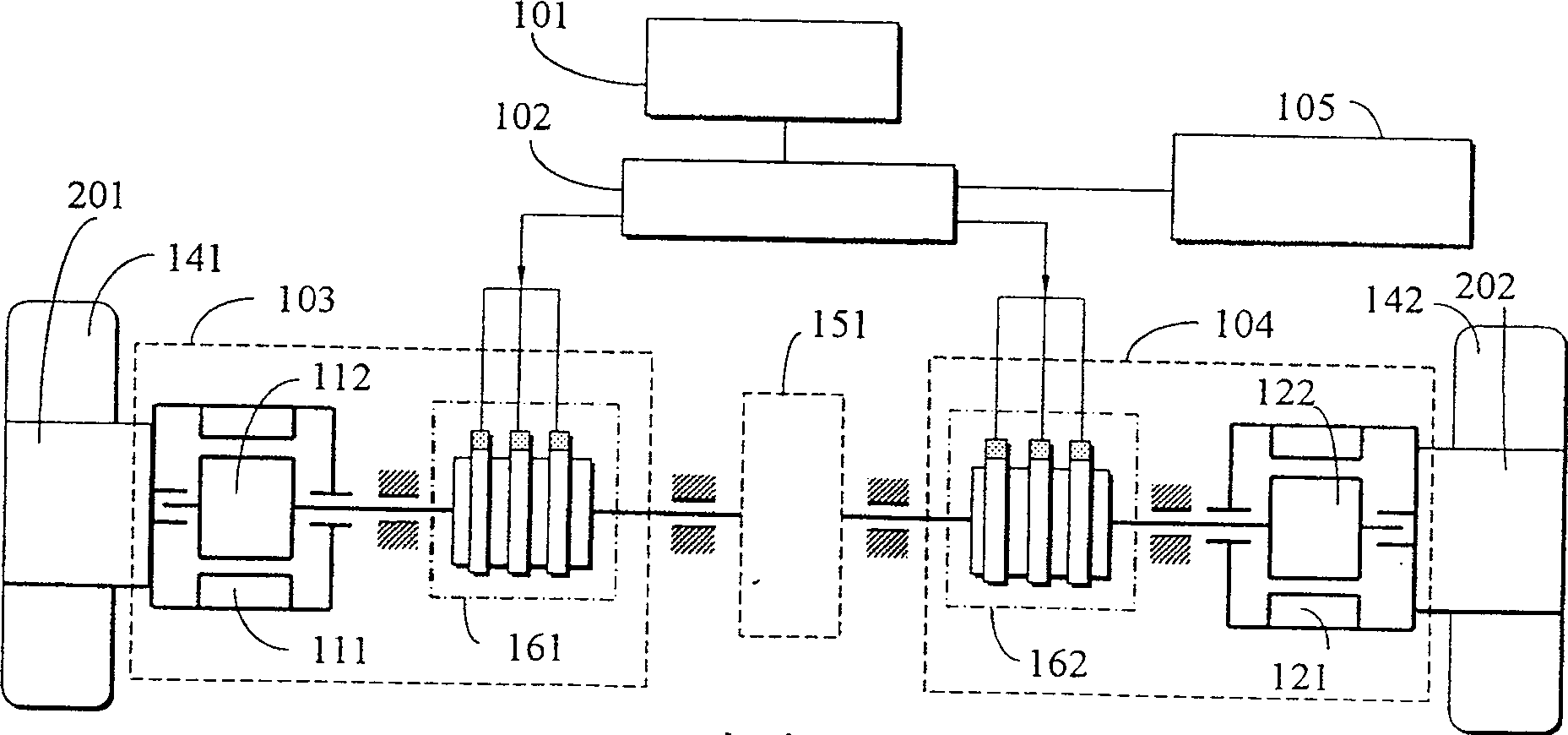

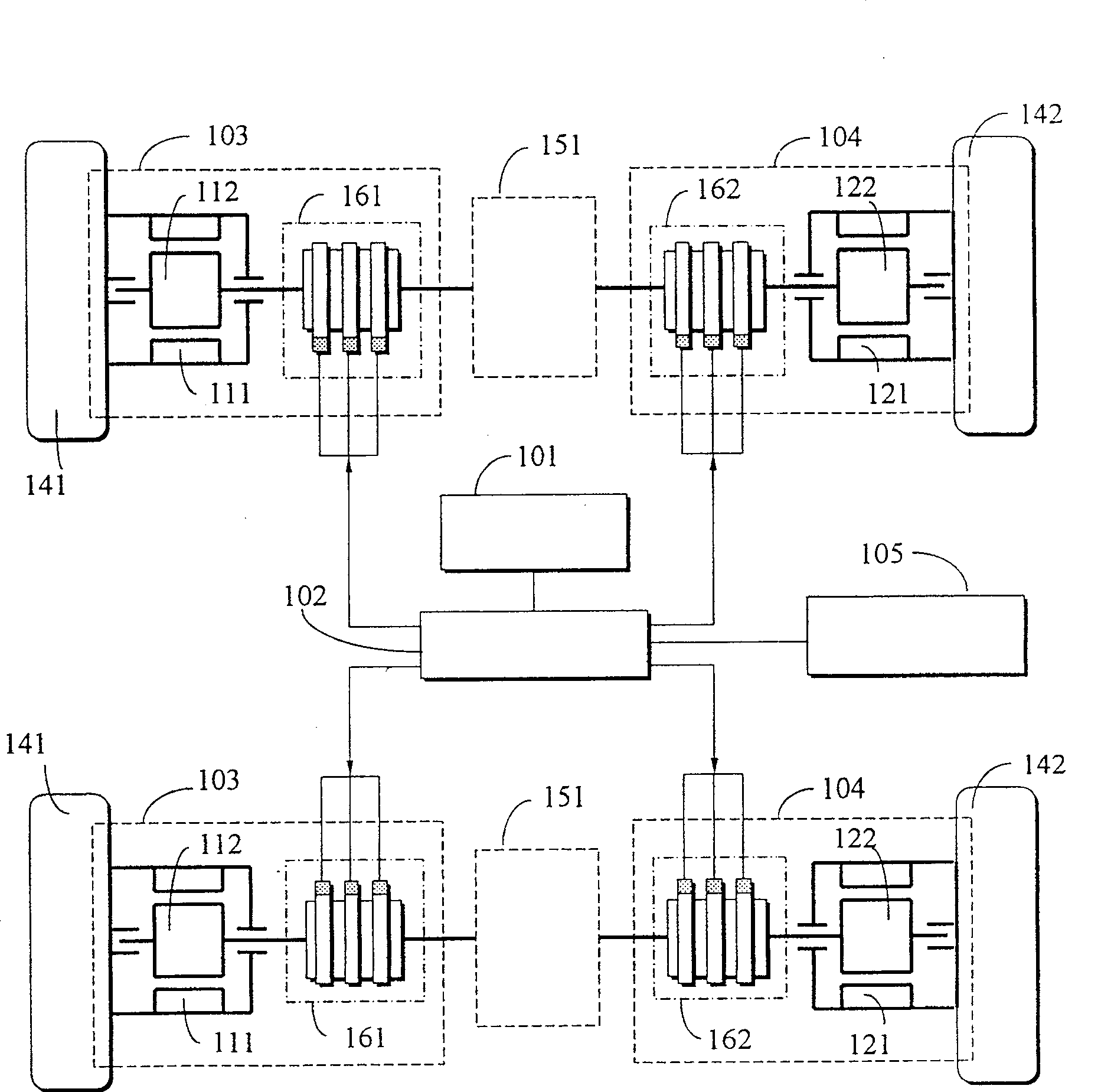

[0016] In the present invention, the power system of the double-acting motor group capable of repelling the differential drive is taken as an example of a power system composed of two sets of double-acting motors that can be driven at the same speed and in the same direction or can be driven in a curve that can repel the differential action, as follows: illustrate:

[0017] Such as figure 1 As shown, in the present invention, the differentially driven double-acting motor unit power system can be rejected, and the embodiment of the drive system is composed of two groups of double-acting motor units, which mainly includes:

[0018] Control command input device 101, the control command input device 101 is composed of electromechanical or solid-state circuit elements to generate analog or digital control signals for controlling the drive control device 102, and then the drive control device 102 controls two groups of double-acting motor groups 103 and 104 are used for forward rot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap