Thread-tension adjusting device of sewing machine

A technology for adjusting devices and sewing machines, applied in tension devices, sewing machine components, and ferrule mechanisms for sewing machines, etc., can solve the problems of different touch feeling, different solenoid characteristics, different surface finish, etc., to reduce deviation and achieve consistent touch feeling. , improve stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

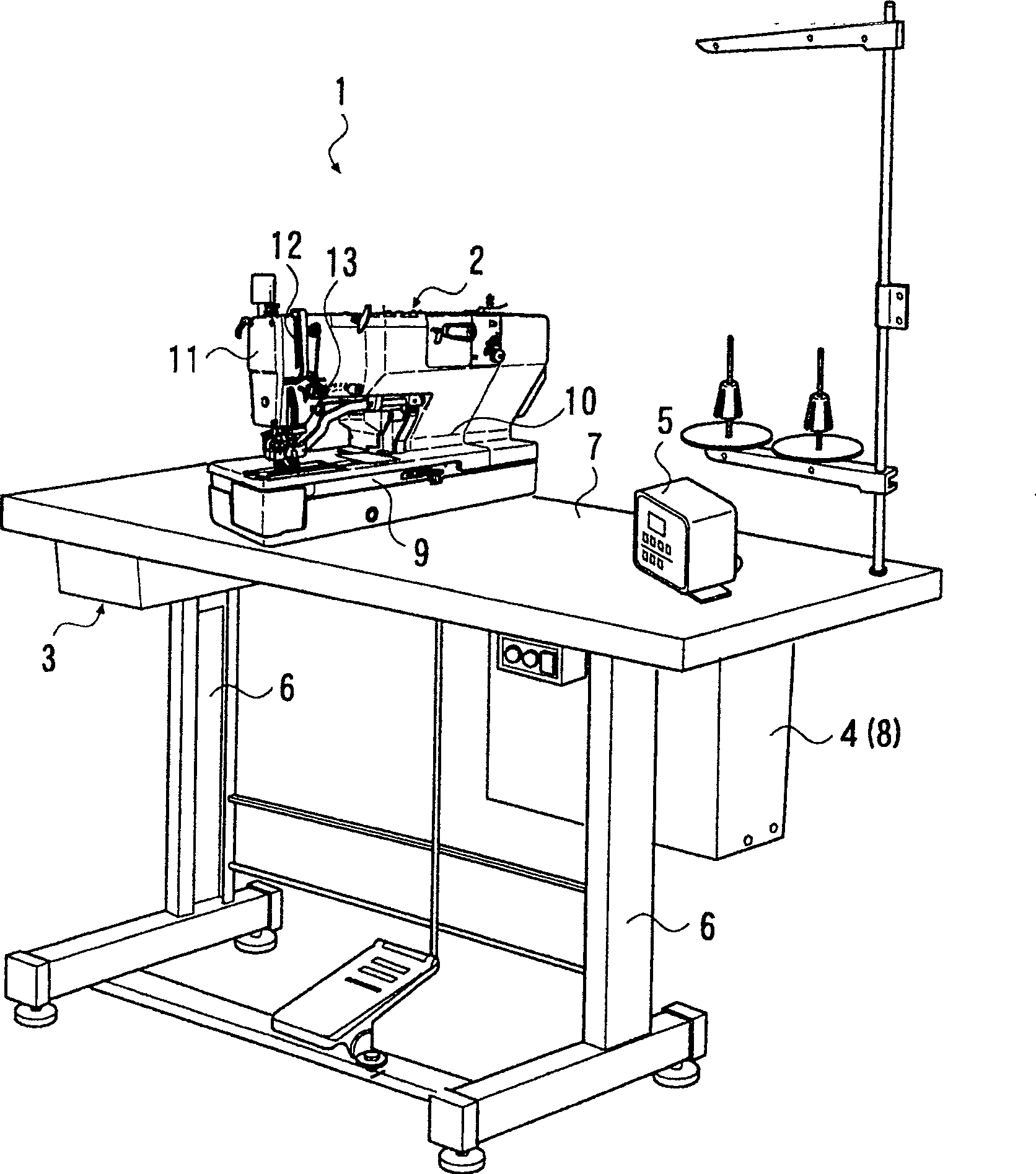

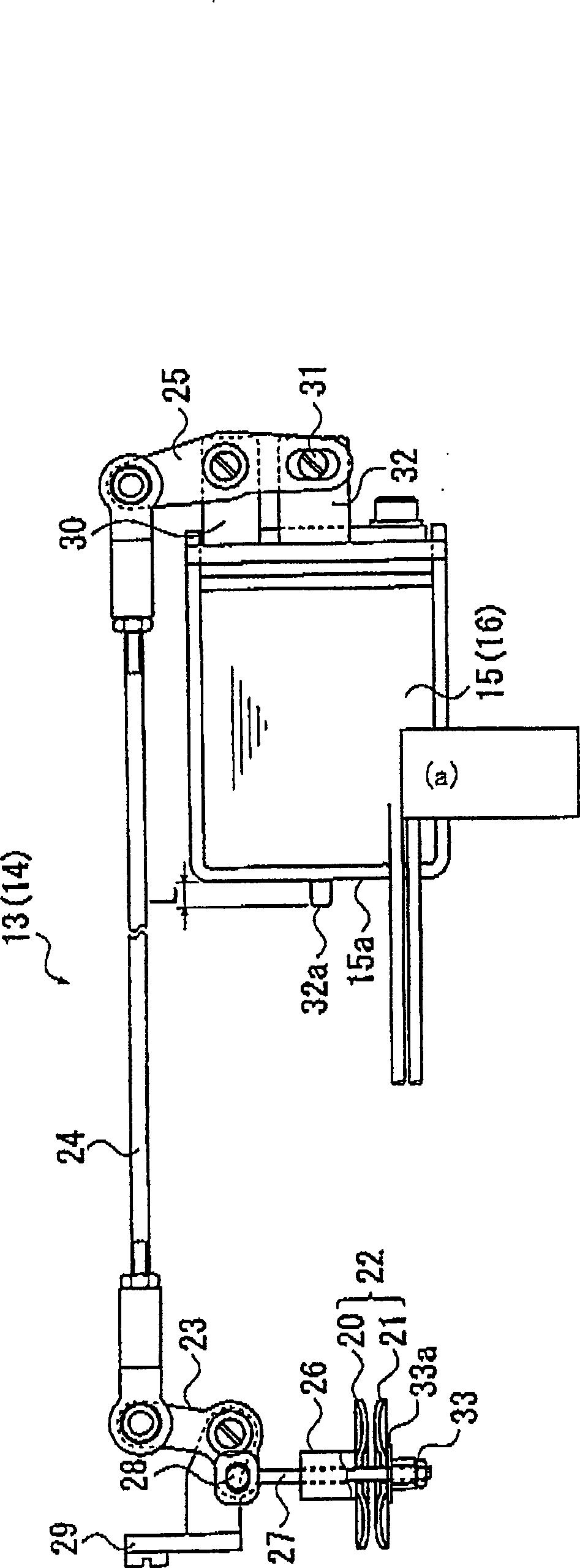

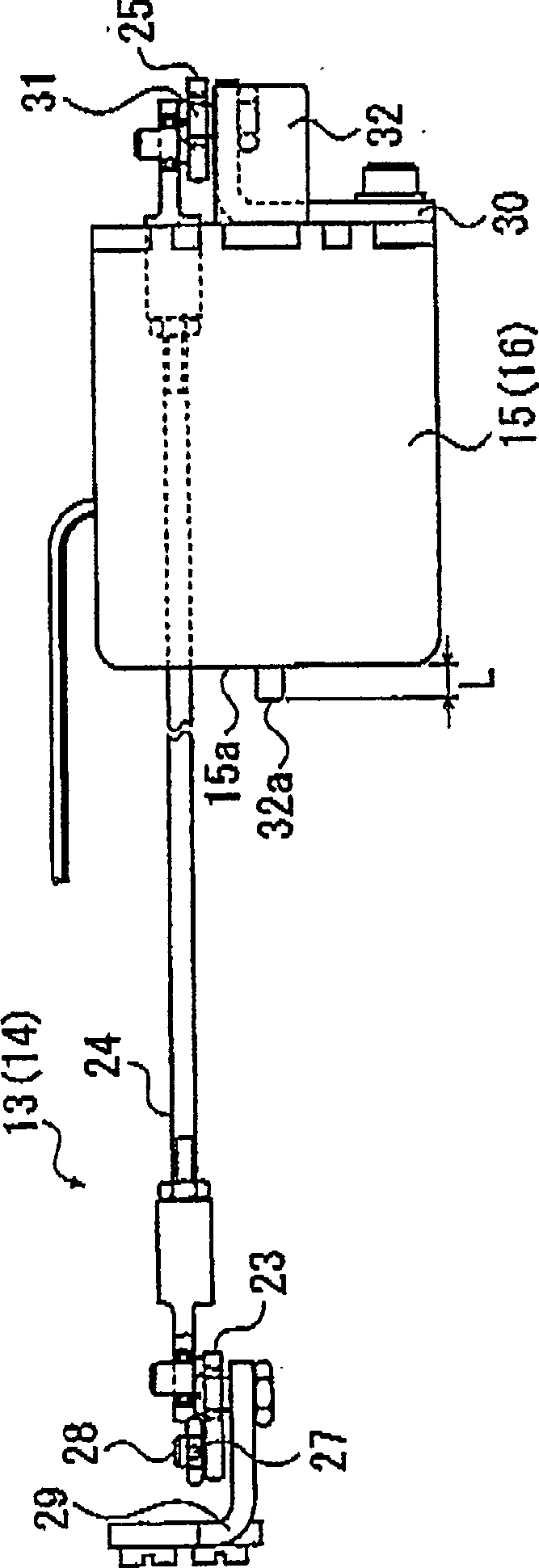

[0032] Hereinafter, embodiments applicable to the present invention will be specifically described with reference to the drawings. However, the scope of the invention is not limited to the illustrated examples.

[0033] Such as figure 1As shown, the sewing device 1 has: a sewing machine body 2 for a circular sewing machine that applies a locking seam around a circular or straight buttonhole, a standing leg portion 6,6 and a top plate arranged on the leg portion 6,6 7's sewing machine console 3, the control device 8 ( image 3 As shown), the distribution box 4 is operated by the operator and the operation panel 5 outputs the operation signal to the control device 8 .

[0034] The sewing machine body 2 has a machine part 9, a vertical body part 10 erected at the rear end of the machine part 9, and a machine head extending approximately parallel to the machine part 9 from the top of the vertical body part 10. 11, and has: a machine needle that moves up and down at the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com