Leaded light lens and luminous diode packaging structure having same

A technology of light-emitting diodes and packaging structures, which is applied to lenses, optics, optical components, etc., can solve the problems of high cost, complicated assembly, and large loss of light energy, and achieve the effects of reducing manufacturing costs, saving the number of mold cores, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

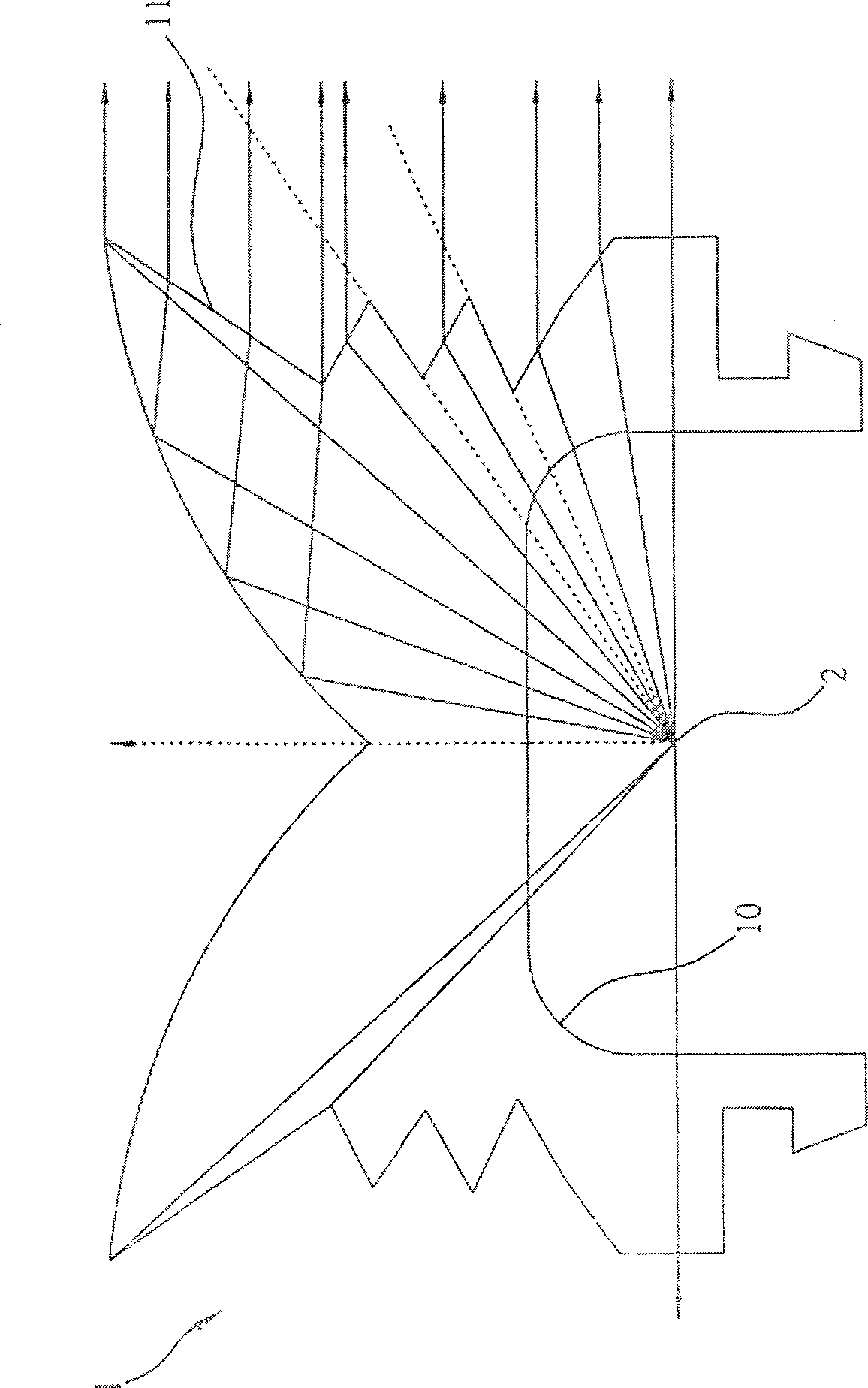

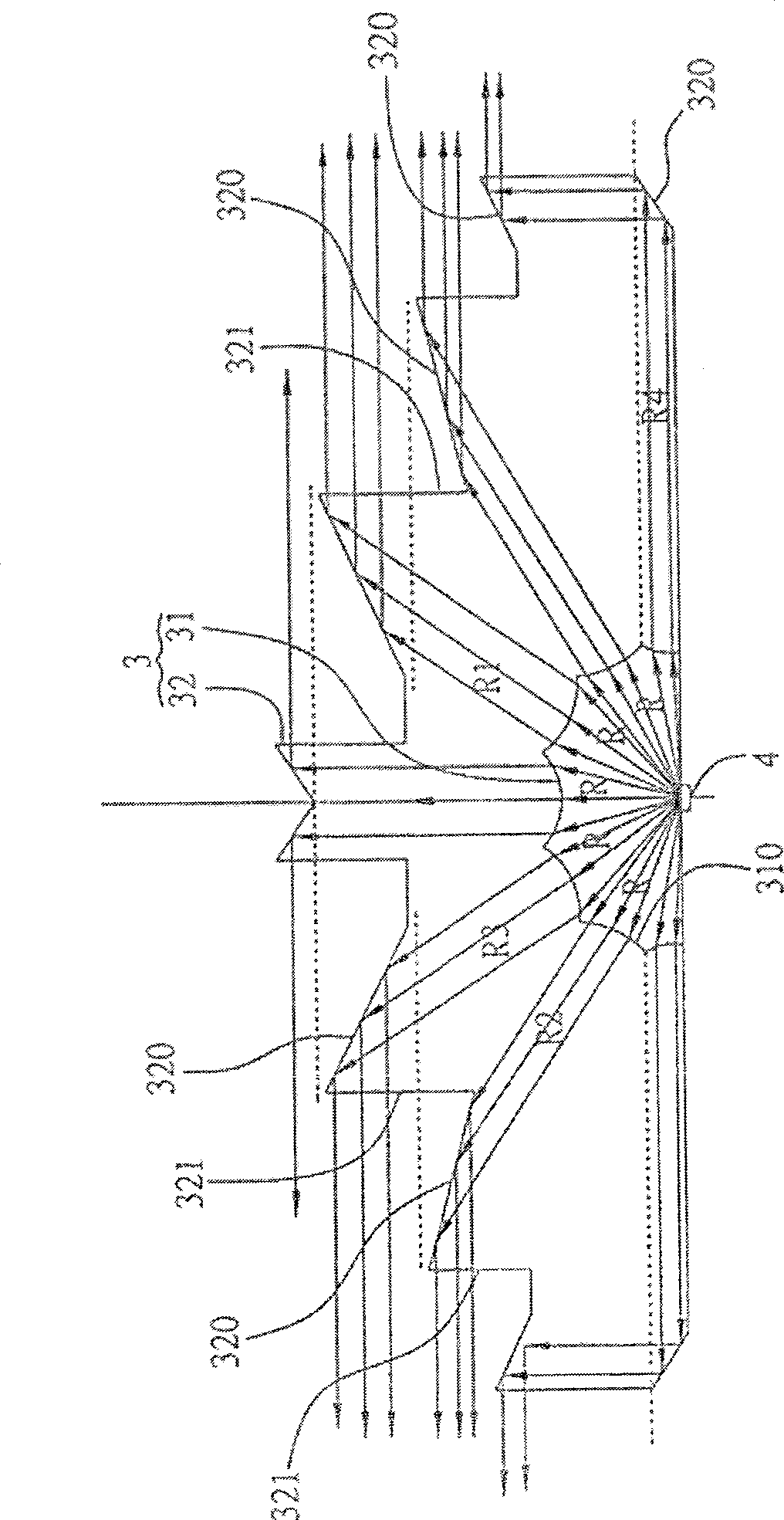

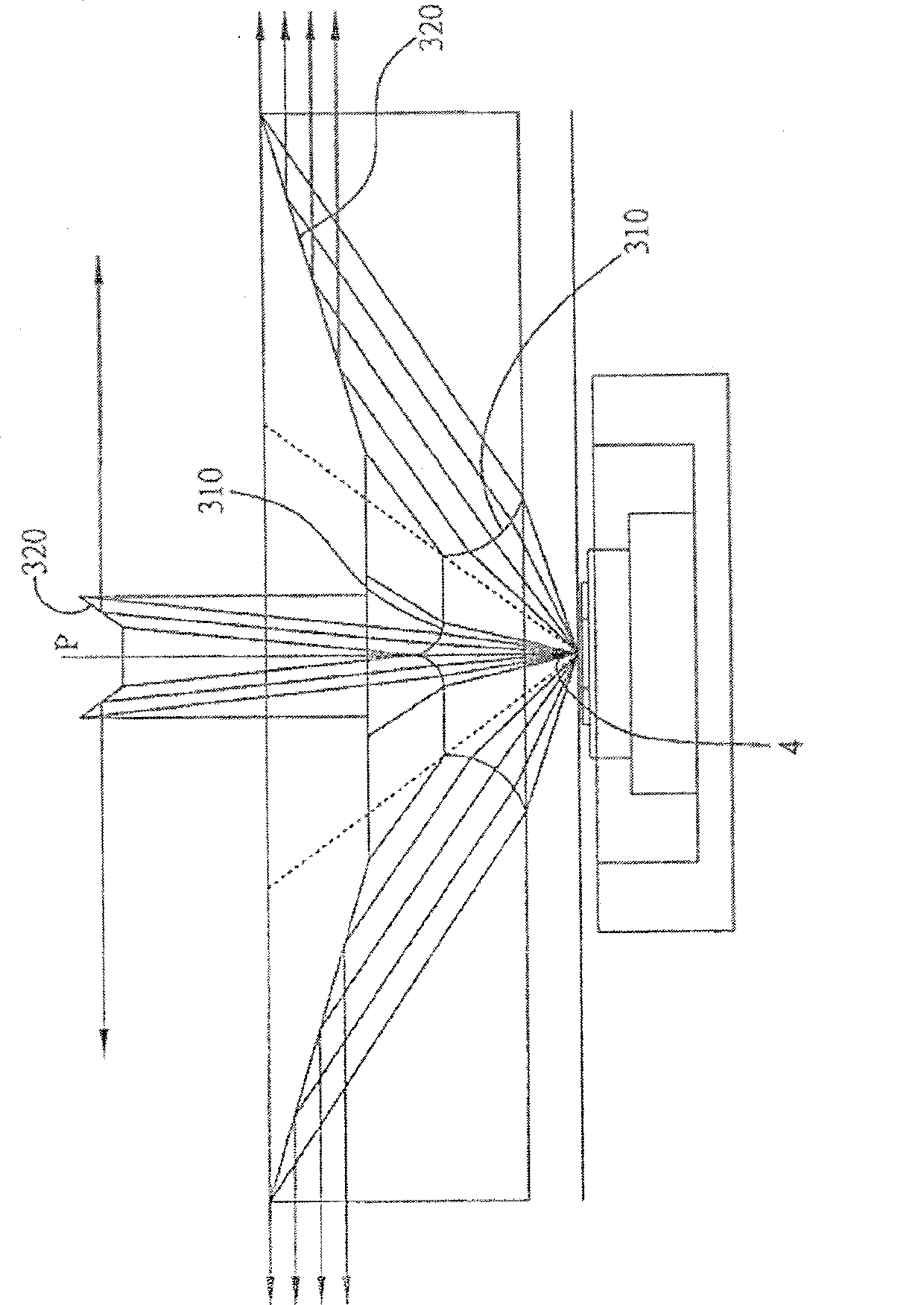

[0027] see figure 2 , which is a schematic diagram of the light guide lens of the present invention, the light guide lens of the present invention is used to modulate the incident light R in each direction and emits toward the side, the light guide lens 3 includes: a lens with a light incident surface 31 and a light exit surface 32 The main body 3 is made of resin or polymer transparent material, etc.; multiple refraction structures 310 arranged on the light-incident surface 31 are used to refract light R to turn to the light-exit surface 32, and a single refraction structure 310 makes incident light rays of different angles R parallel refraction; and a plurality of reflective structures 320 arranged on the light exit surface 32, used to reflect the light from each corresponding part of the refraction structure 310 to the side light exit of the lens body 3, and parallel refraction from the single refraction structure 310 All the light rays correspond to the single reflective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com