Method for determining the time of hot rolling heating stove bar plate leavings in furnace

A determination method and heating furnace technology, which is applied in the field of determination of the remaining slab time in the furnace of the hot rolling heating furnace, can solve the problems of inability to adapt to hot rolling production, inaccurate furnace gas temperature setting, and inaccurate calculation of heating Furnace slab remaining time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

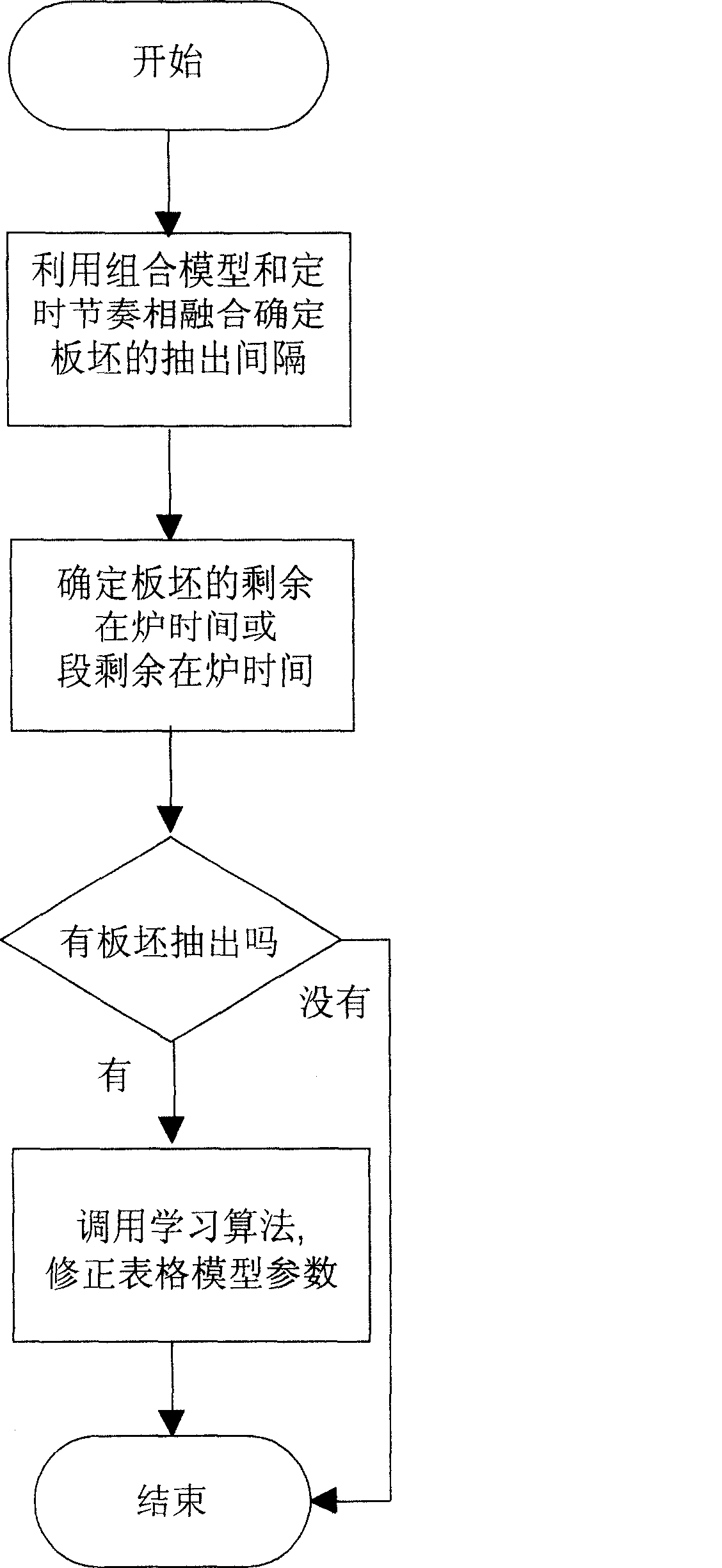

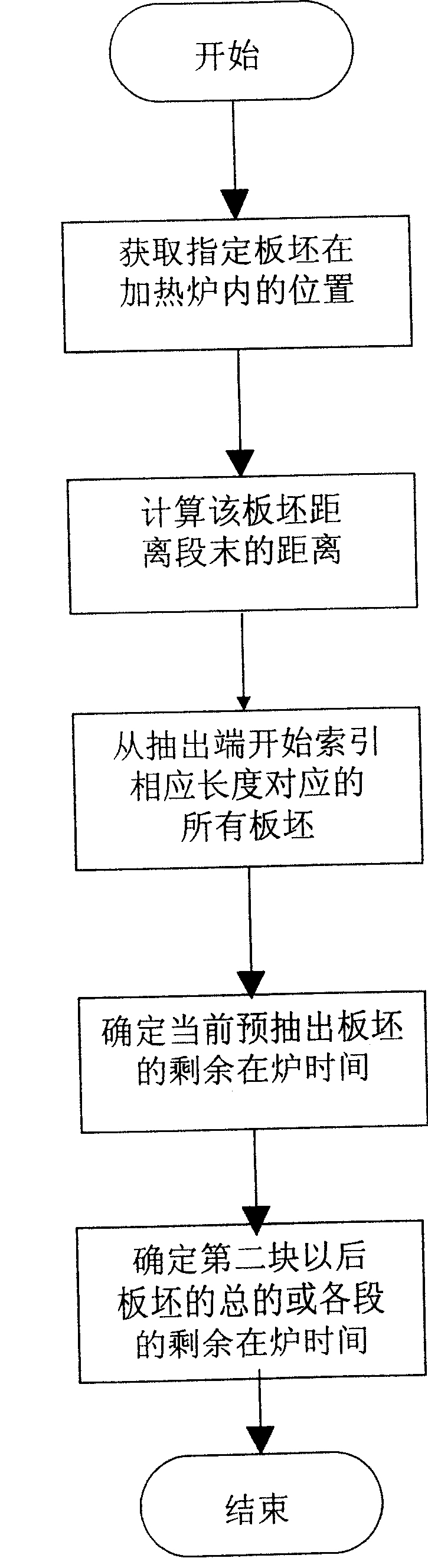

[0037] see figure 1 As shown, the hot rolling heating furnace slab remaining in the furnace time determination method of the present invention comprises the following steps:

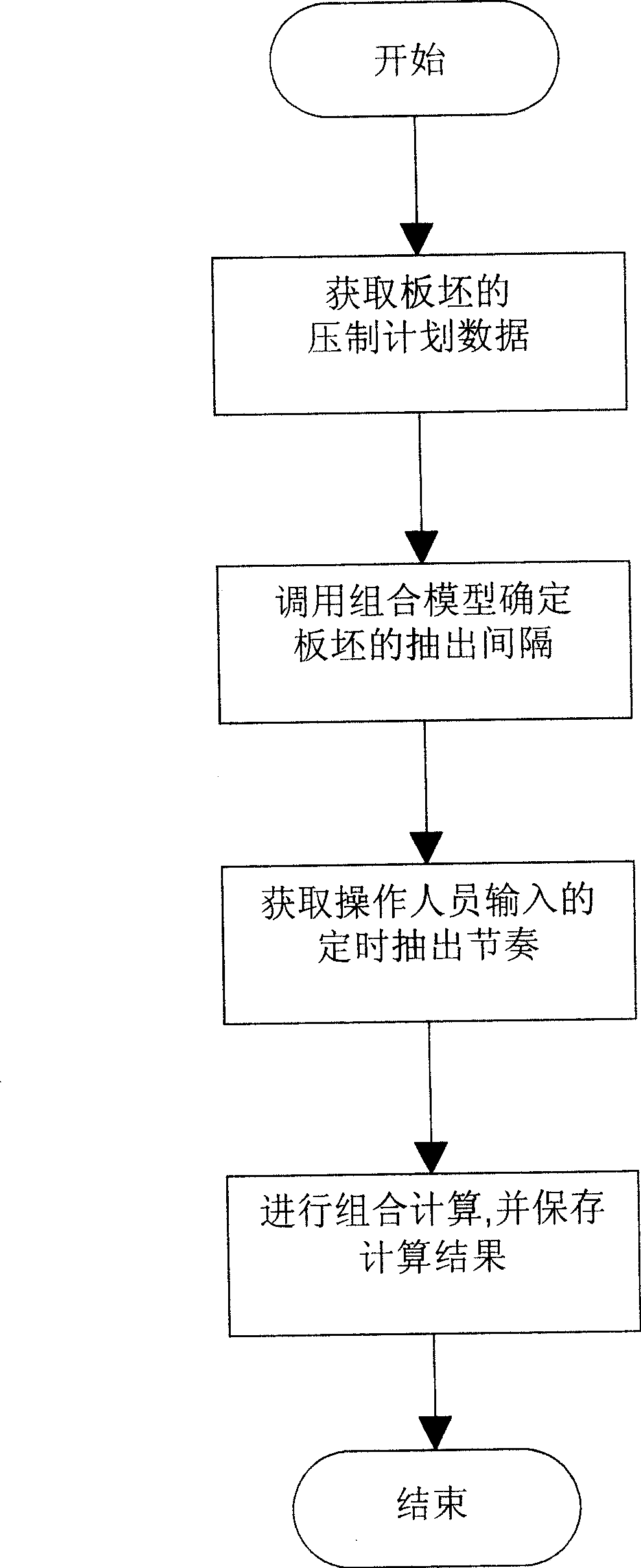

[0038] Firstly, obtain the size and specification data of the slab in the heating furnace from the rolling plan, that is, the length of the slab, the width of the finished product, and the thickness of the finished product, as well as the length grade of the slab, the grade of the finished product width, the grade of the thickness of the finished product, and the hardness grade, and call the statistical parameter model Calculate the extraction interval of the slab in the heating furnace with the tabular parameter model, add the calculation results, and then merge with the current timing steel extraction interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com