Fuel Injection Control System for Internal Combustion Engine

A fuel injection and control system technology, applied in fuel injection control, engine control, internal combustion piston engine, etc., can solve the problems of liquid fuel entering the cylinder, increasing the possibility of soot, toxic unburned components, etc., to reduce dilution and accurately predict Pre-ignition, the effect of reducing pre-ignition combustion events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

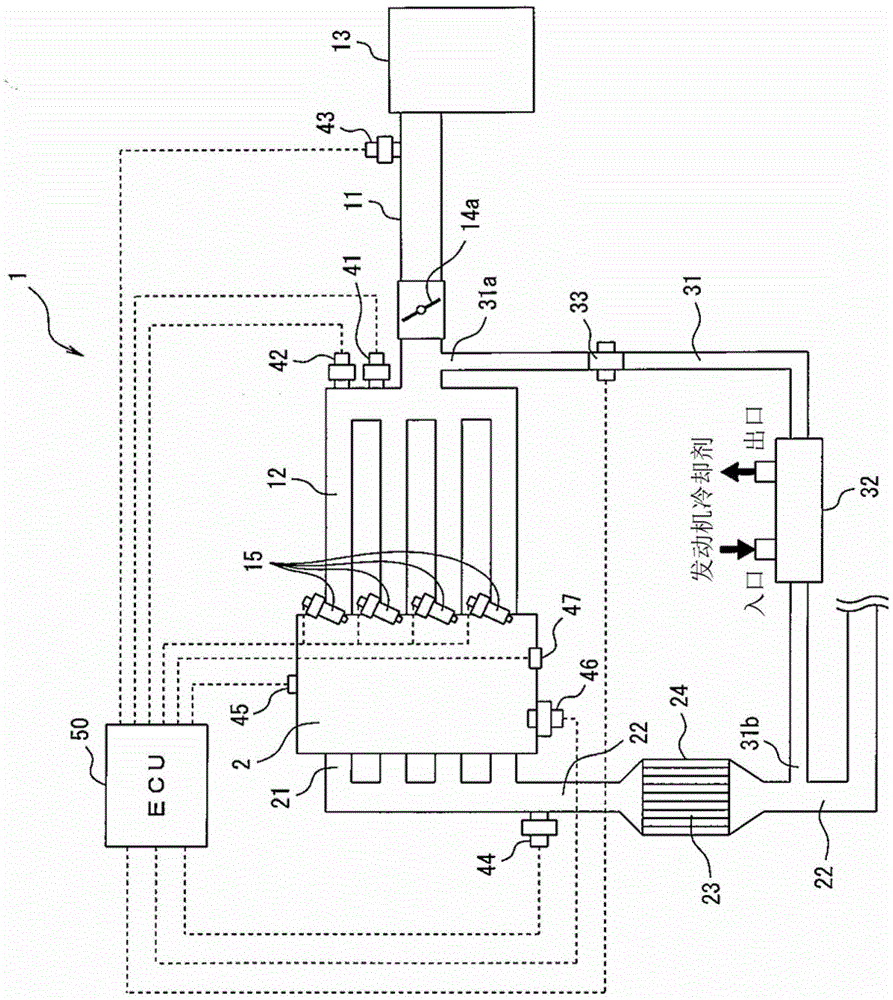

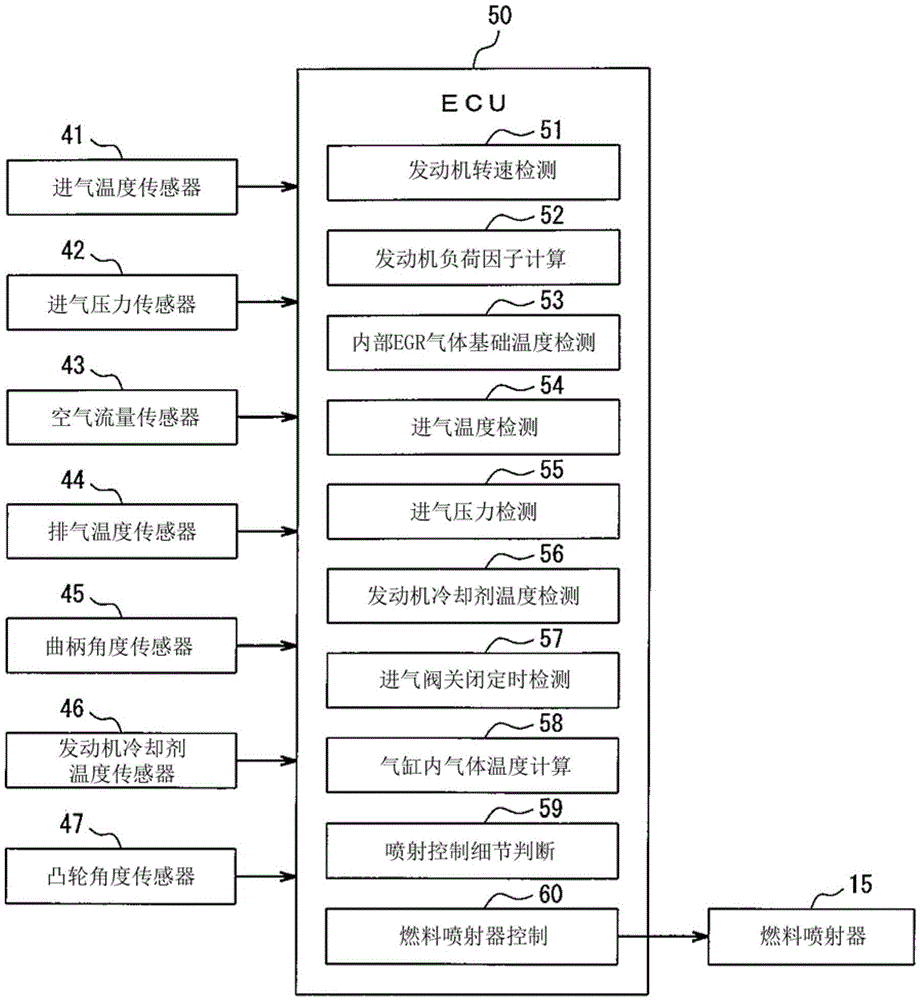

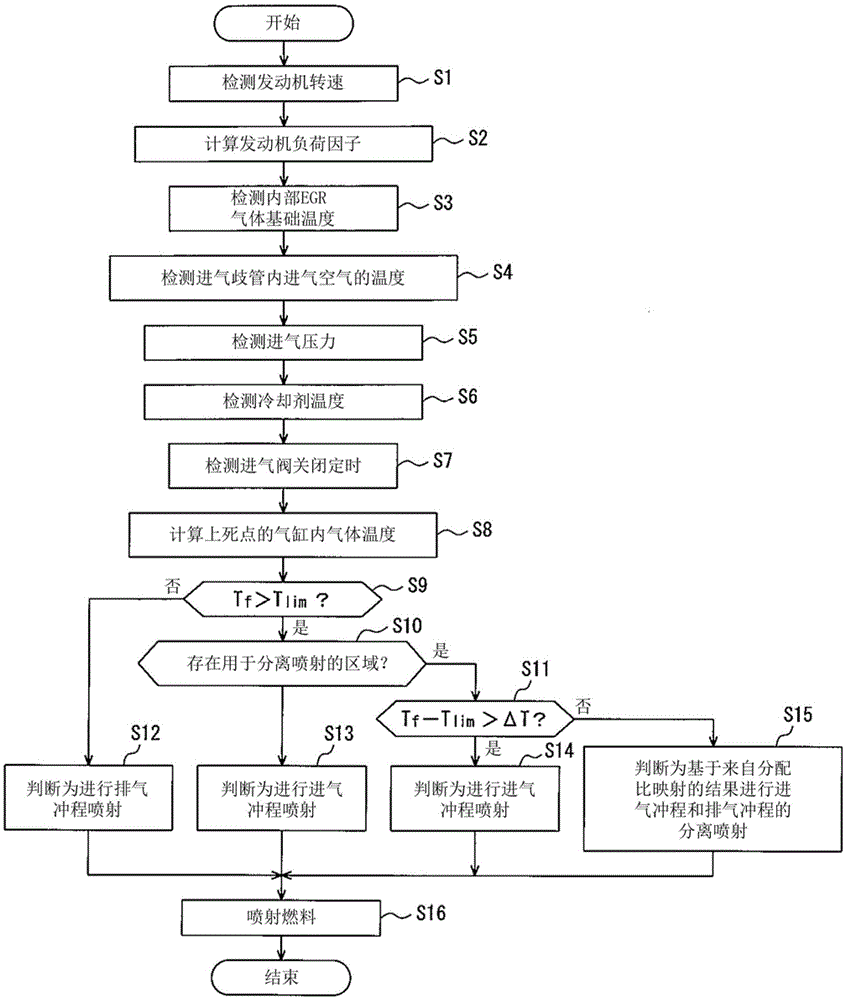

[0064] Embodiments of the present invention are described with reference to the drawings. As the present embodiment, a vehicle having an internal combustion engine fuel injection control system will be described.

[0065] figure 1 is a schematic diagram of an exemplary configuration of the vehicle 1 according to the present embodiment. Such as figure 1 As shown in , according to the present embodiment, the internal combustion engine 2 mounted to the vehicle 1 is a four-stroke internal combustion engine 2 . Furthermore, according to the present embodiment, the internal combustion engine 2 is a four-cylinder internal combustion engine.

[0066] In the intake system of the internal combustion engine 2 , an intake passage 11 is connected to an intake manifold 12 communicating with a combustion chamber of each cylinder of the internal combustion engine 2 . The intake passage 11 includes an air cleaner 13 on the upstream side thereof and an electronically controlled throttle bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com