Fixing structure of optical film

A technology of fixed structure and optical film, applied in optics, nonlinear optics, instruments, etc., can solve the problems of insufficient strength, falling, and large relative movement of the film, so as to reduce the warping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

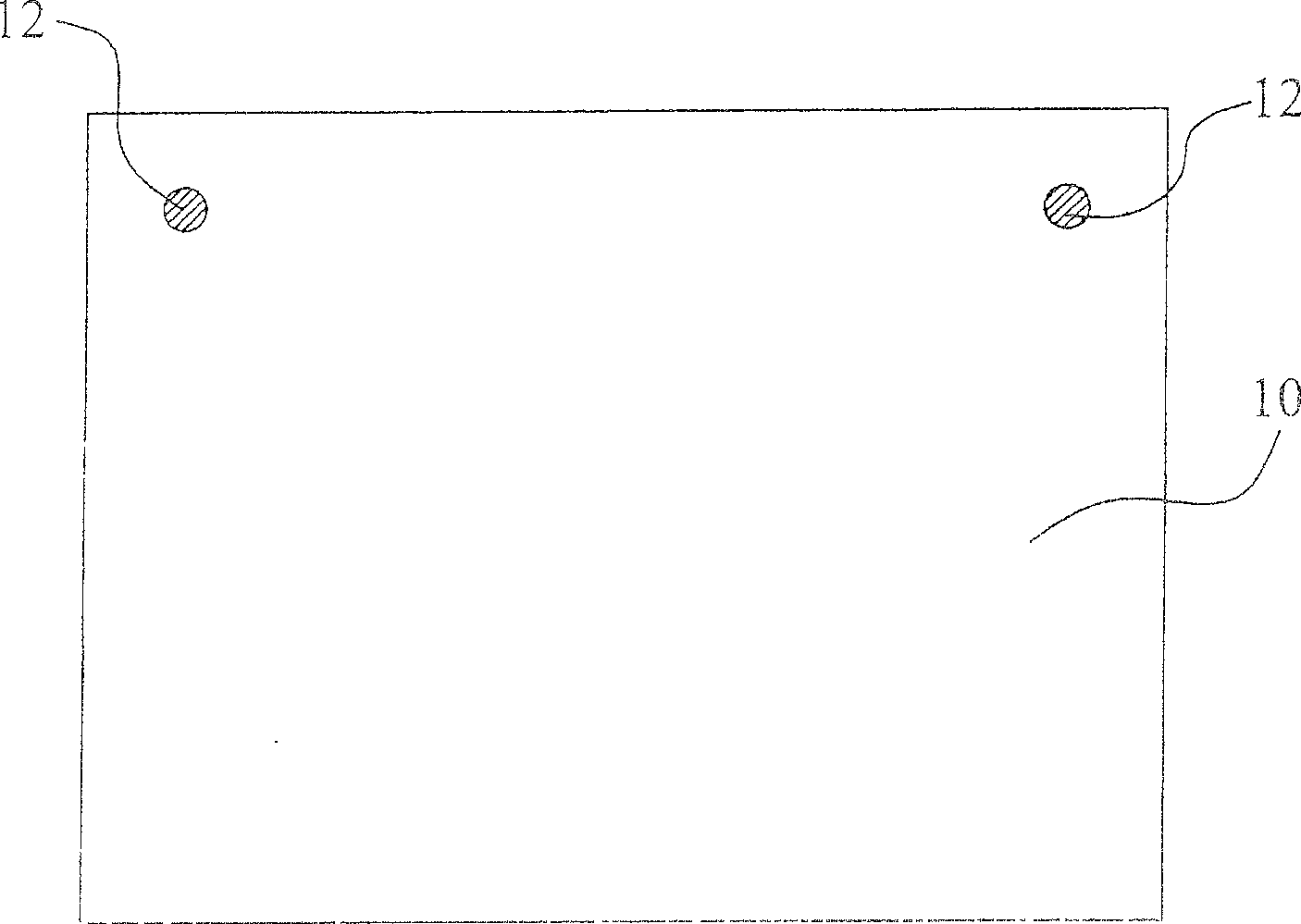

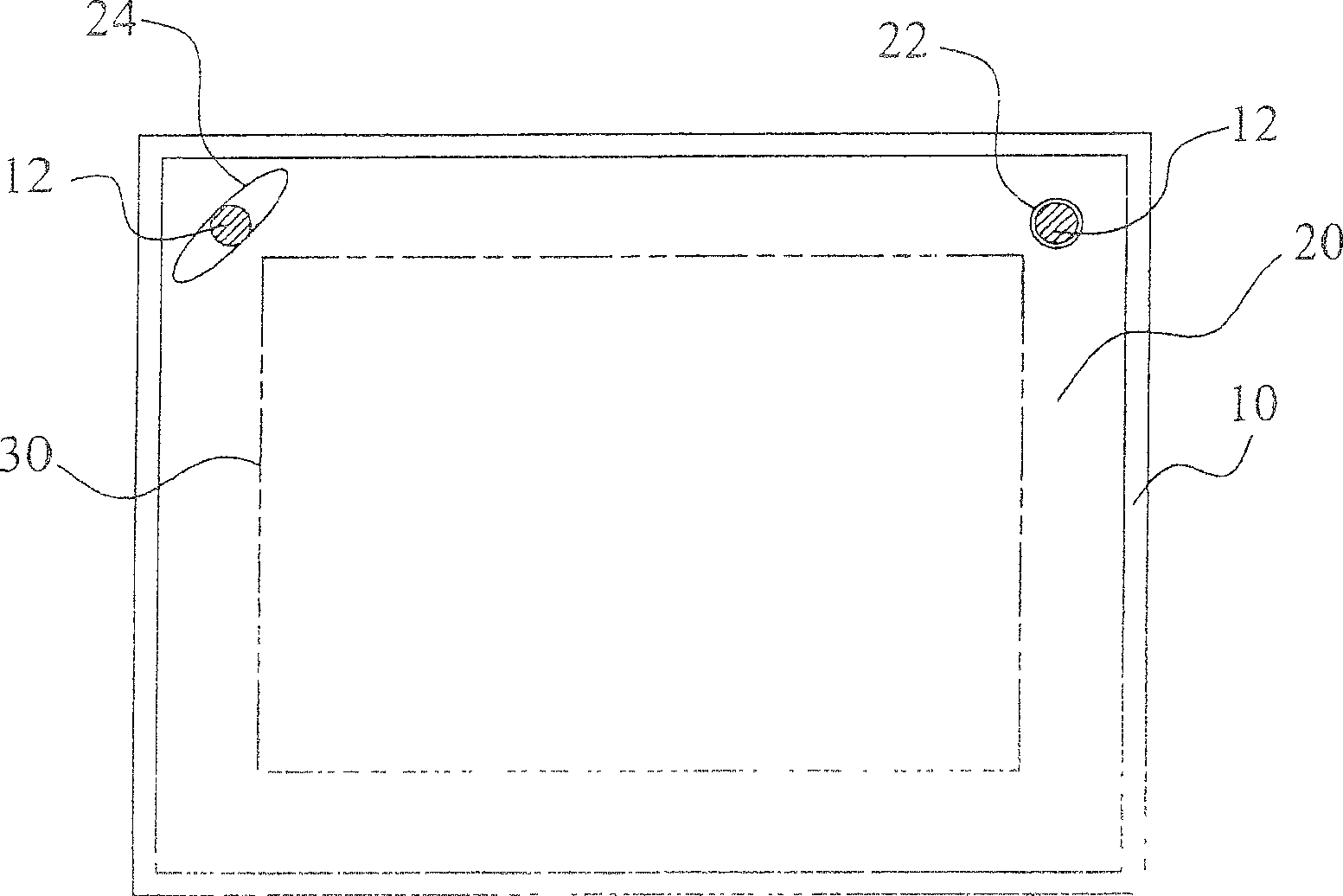

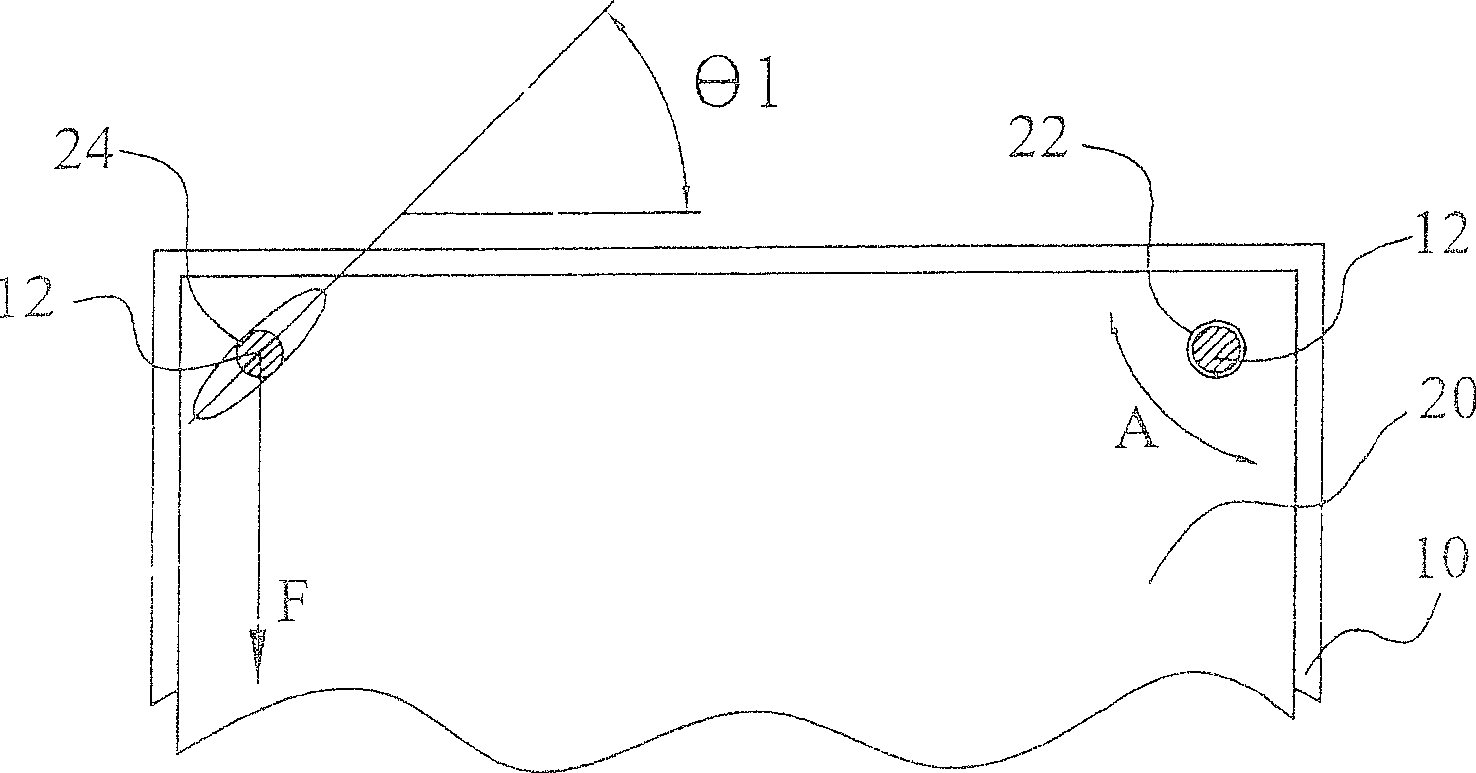

[0035] Figure 1A and Figure 1B Shown is a schematic front view of an embodiment of the fixing structure of the optical film according to the present invention. In this embodiment, if Figure 1A As shown, a bottom plate 10, the bottom plate 10 can be the back plate of the backlight module, the back frame, the side frame or other supporting plates that can carry the flat film. On the bottom plate 10, two fixing elements 12, such as fixing pins, are disposed thereon. see next Figure 1B , a first film material 20 is placed on the bottom plate 10 , and a first fixing hole 22 and a second fixing hole 24 are disposed on the first film material 20 . Wherein, the first fixing hole 22 and the second fixing hole 24 are respectively arranged at the horizontal position on the upper side of the first film material 20, and the fixing elements 12 on the bottom plate 10 pass through the first fixing hole 22 and the second fixing hole respectively. 24 , wherein the first fixing hole 22 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com