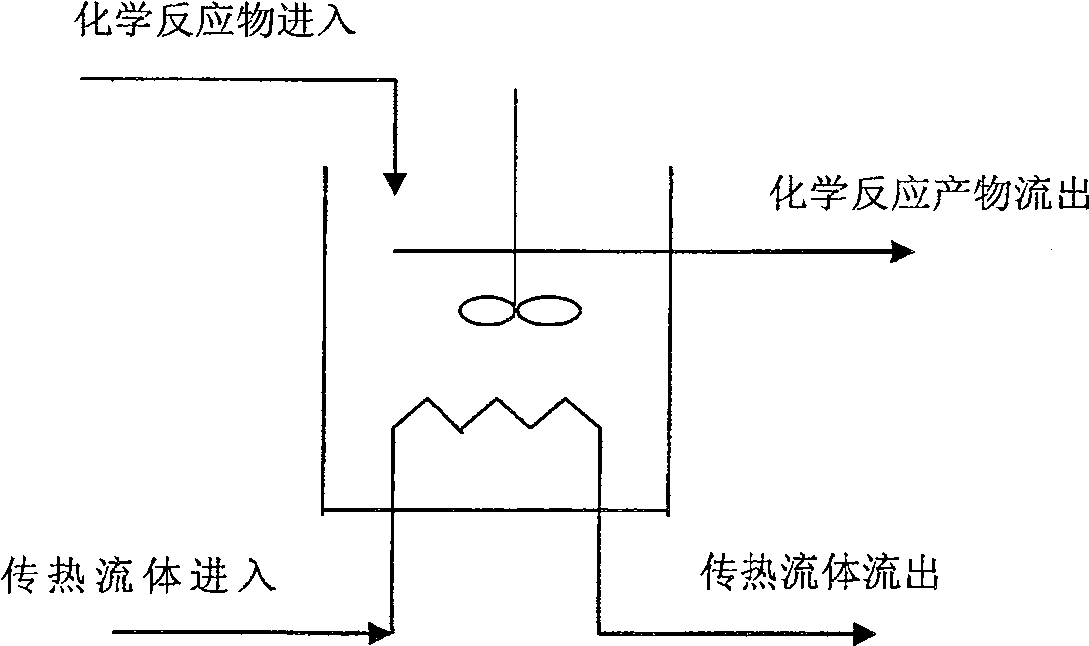

Groove type reactor non-linear predication control method based on multi-kernel support vector machine

A kernel support vector machine and support vector machine technology, applied in adaptive control, general control system, control/regulation system and other directions, can solve the problems of modeling accuracy dependence, large amount of calculation, poor real-time performance, etc., to avoid online iteration Approximate optimization, simple identification process, and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

[0032] 1. Nonlinear prediction model based on multi-core support vector machine

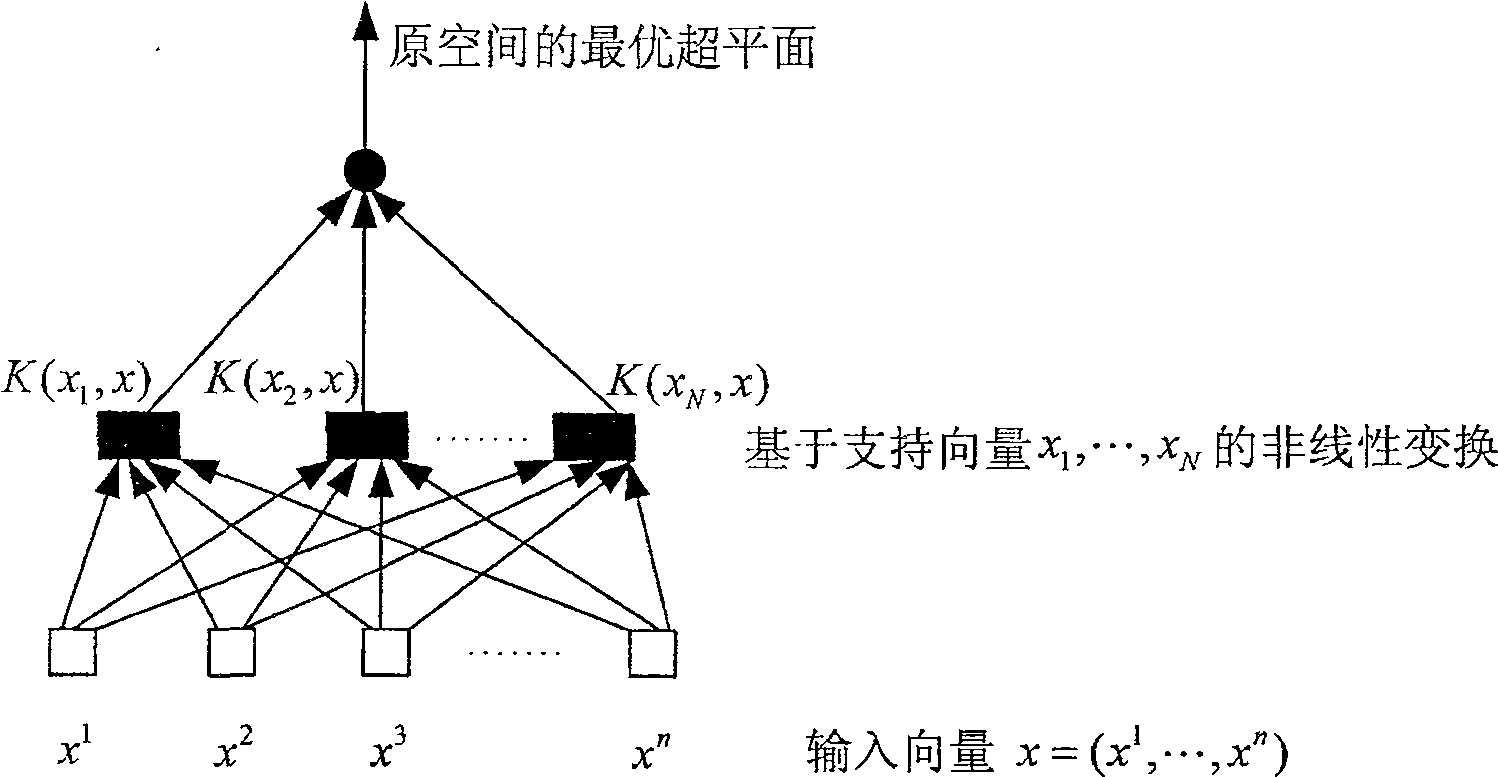

[0033] A support vector machine is a novel learning machine. figure 2 A block diagram of the support vector machine itself is given. The basic idea of the support vector machine is to map the linearly inseparable low-dimensional space data into a linearly separable high-dimensional space through the nonlinear inner product kernel function, and perform linear regression fitting in this high-dimensional space.

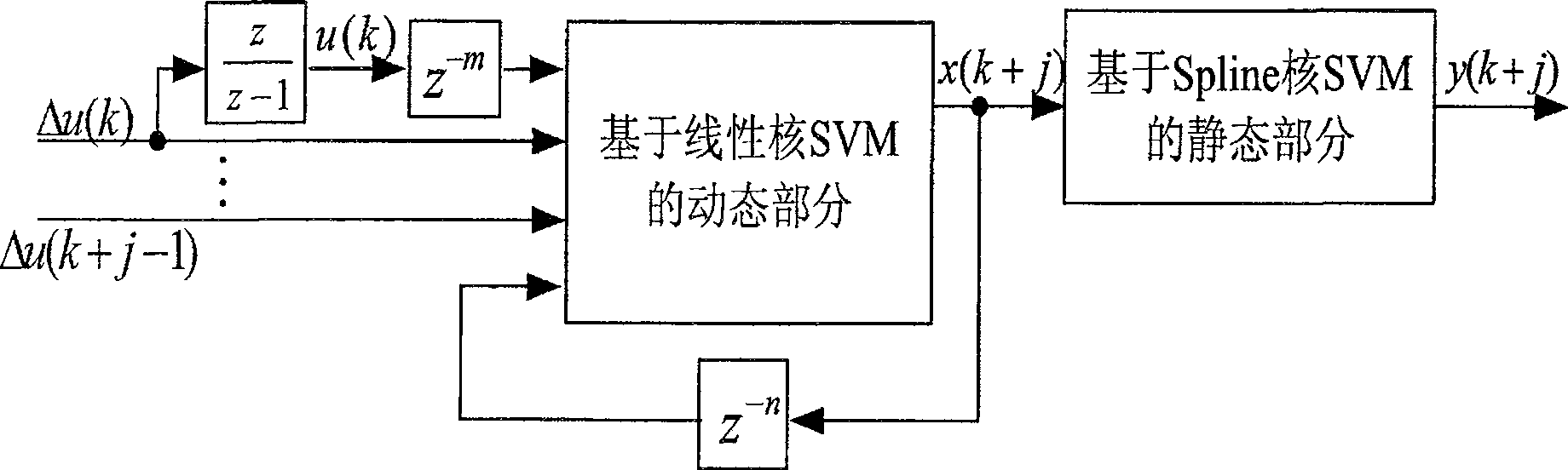

[0034] The nonlinear model structure based on multi-core support vector machine is as follows: image 3 As shown, it includes the concatenation of the dynamic part based on the linear kernel SVM and the static part based on the spline kernel SVM.

[0035] The linear dynamic part is described by

[0036] x(k+j|k)=f[x(k),...,x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com