PID control system and parameter setting method

A control system and parameter tuning technology, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

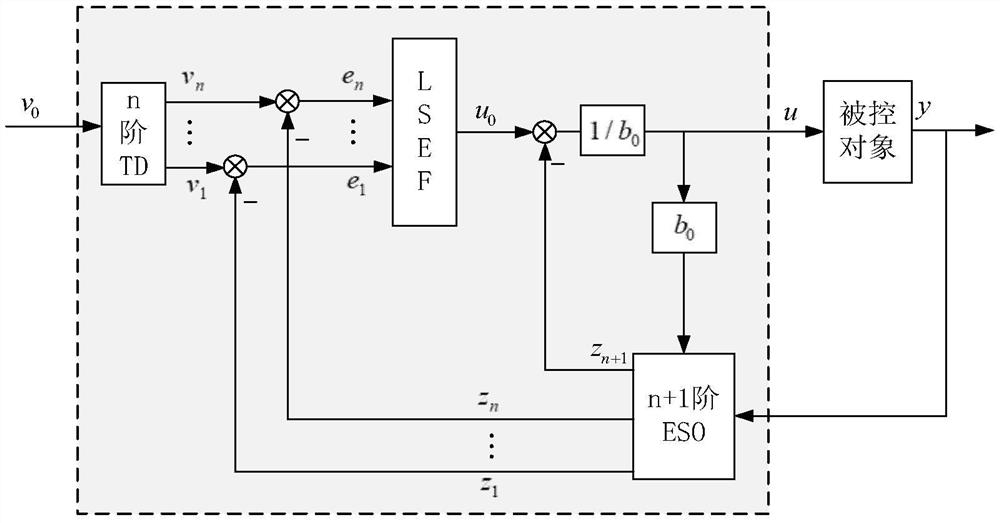

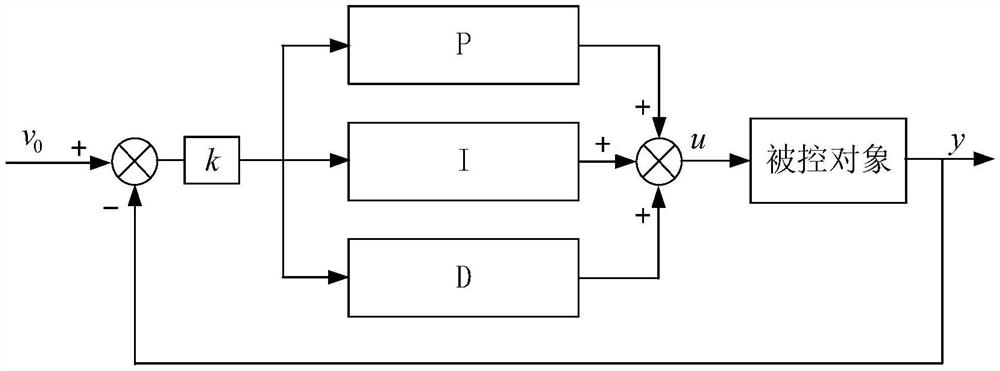

[0063] A PID control system in this example, such as figure 1 with figure 2 As shown, it includes the controlled object and the PID controller. The PID controller includes a proportional unit P, an integral unit I, a differential unit D and a controller gain coefficient k. The transfer function of the PID controller is:

[0064]

[0065] The PID controller is inspired by the linear active disturbance rejection controller, and the transfer function inspired by the PID controller is:

[0066]

[0067] The relationship between the parameters of the PID controller and the parameters inspired by the linear active disturbance rejection controller LADRC is as follows:

[0068]

[0069] Among them, k p is the proportional coefficient; T i is the integration time; k d is the differential coefficient; T d is the differential time; k is the controller gain coefficient; ω 0 is the bandwidth of the extended state observer LESO in the linear active disturbance rejection cont...

Embodiment 2

[0108] This example provides the parameter tuning method of the above PID control system, such as Figure 14 shown, including the following specific steps:

[0109] 1) Perform control algorithm configuration on the control system of the controlled object based on the PID controller; in step 1), the control system of the controlled object includes a DCS control system and a PLC control system.

[0110] 2) Obtain the soaring curve of the controlled object on site, and obtain the steady-state gain K of the controlled object, the time parameter T and the delay time τ of the approximate first-order or second-order inertia plus pure delay system, and the open-loop adjustment time t s1 ;

[0111] 3) Let the PID controller bandwidth ω c The filter parameter ω of the PID controller with the desired closed-loop 0 The ratio of is λ, then k p =2ξλ-λ 2 , k d =(1-2ξλ+λ 2 ); based on the lift curve, set λ, ξ, ω c , the initial value of k, according to the set initial value, calcu...

Embodiment 3

[0126] This embodiment adopts the control system and parameter setting method of the present invention to automatically control the main steam temperature control system of a 330MW circulating fluidized bed unit. The main steam temperature system model of the unit is as follows

[0127]

[0128] Among them, P 1 (s) is the leading region model (°C / %), P 2 (s) is the inert zone model (°C / °C), and the unit step response curve after the two are connected in series is as follows Figure 4 shown.

[0129] The system approximates the FOPTD model as follows:

[0130]

[0131] Parameter tuning methods include:

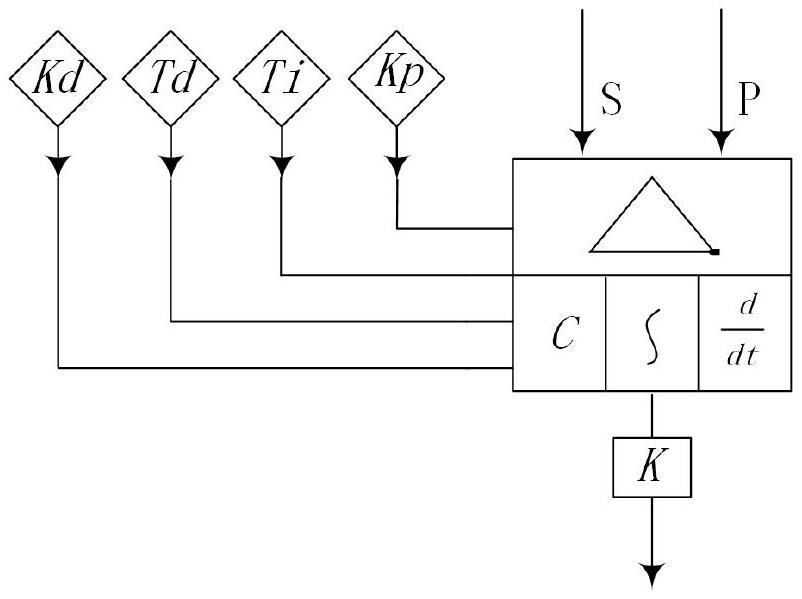

[0132] Step 1, based on the PID controller of the present invention, the control algorithm configuration is carried out on the control system of the controlled object, such as image 3 shown;

[0133] Step 2: Use the soaring curve method on site to obtain the steady-state gain K of the controlled object, the time parameters T and τ of the approximate first-order iner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com