Control loop actuator hysteresis predictive compensation method

A technology of control loop and compensation method, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve the problems of unclear meaning of parameters, hysteresis, and many parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

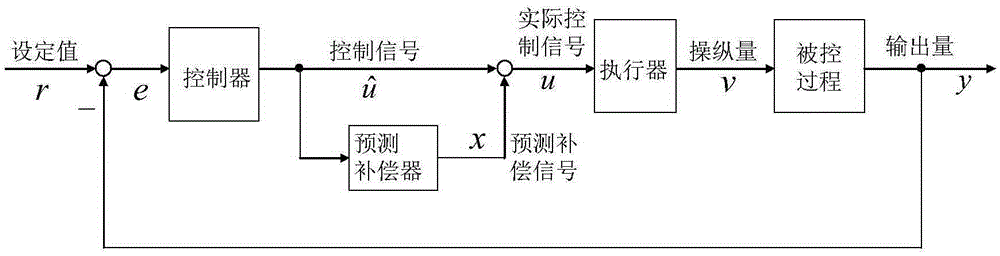

[0069] Such as figure 1 As shown, in the structural diagram of the control loop actuator hysteresis compensation system of the method of the present invention, the input of the predictive compensator is the control signal The output is the predicted compensation signal x(t), and the actual input signal of the actuator is u(t).

[0070] The focus of the invention is to design a predictive compensator capable of compensating the hysteresis effect of the actuator, which is used to improve the oscillation response of the control loop caused by the hysteresis characteristic of the actuator. For the convenience of description, taking the valve as an example, it is now assumed that the mathematical model P(s) of the controlled object from the manipulated quantity to the output quantity is:

[0071] P ( s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com