Non-linear model predication control method of tank reactor based on on-line support vector machine

A model predictive control and support vector machine technology, applied in adaptive control, general control systems, control/regulation systems, etc., can solve problems such as relying on prior knowledge, inability to model correction, difficult to determine geometric topology, etc., and achieve nonlinear High fitting accuracy, online self-calibration, and simple identification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

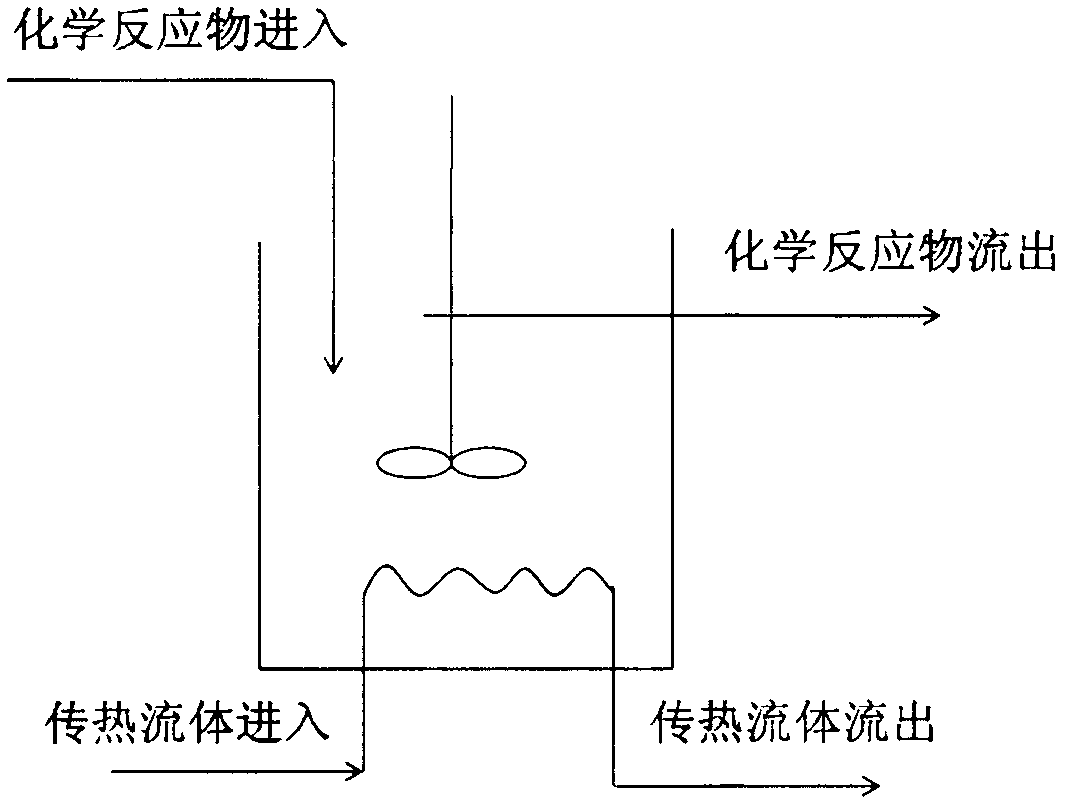

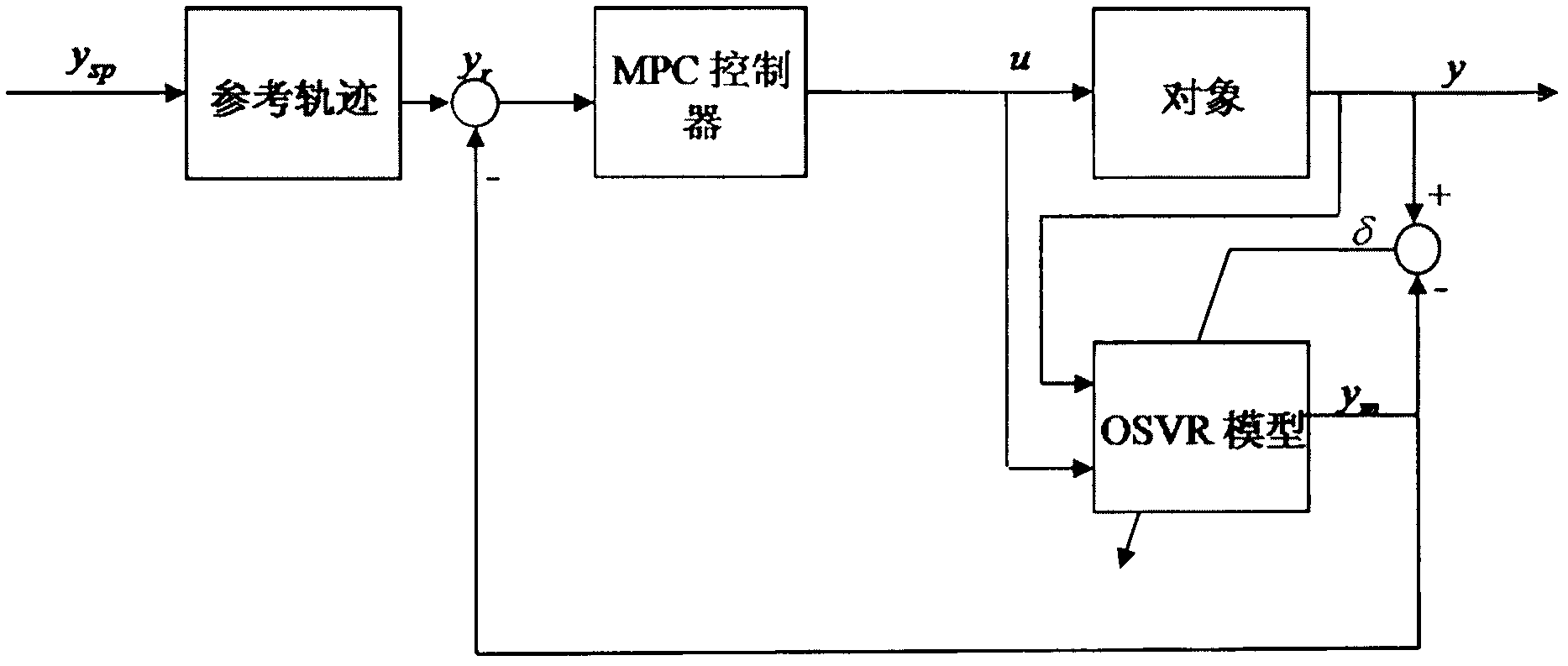

[0034] 1. Nonlinear prediction model based on online support vector machine

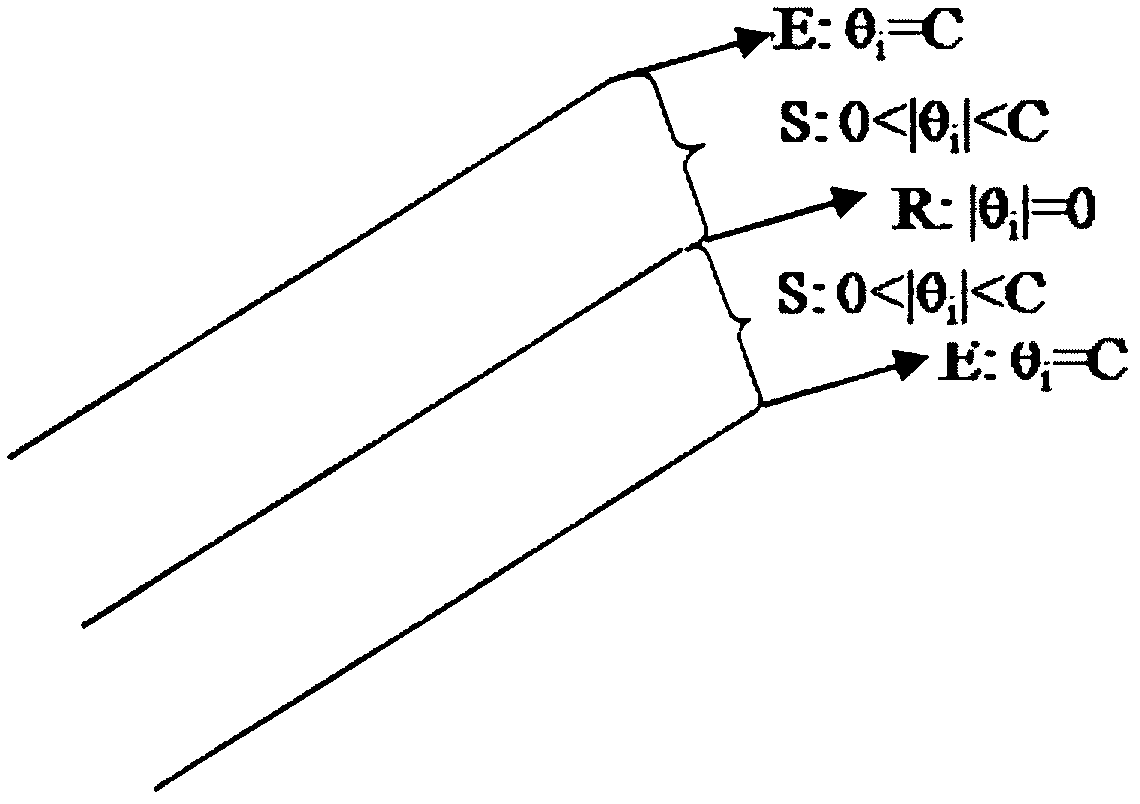

[0035] Online Support Vector Machine (OSVR) is a new training method for SVM. figure 2 The sample classification diagram of online support vector machine is given. Through Lagrangian multipliers and Karush-Kuhn-Tucker (KKT) conditions, the training data can be divided into three sets: error support vector set E={i=||θ i |=C, |h(x i )|≥ε}, boundary support vector set S={i=|0i |i )|=ε}, remaining sample set, R={i=||θ i |=0, |h(x i )|≤ε}.

[0036] definition and h(x i ) = f(x i )-y i , the boundaries of S and E are variable, and their boundaries will change when new samples are added. The main steps of the algorithm are: when adding a new sample x c to the training set, gradually changing θ c and h(x c ) until x c Enter one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com