Coal pushing and charging car automatic aligning control method based on machine vision technology

A machine vision and automatic alignment technology, applied in the control of using feedback, etc., can solve the problems of accurate automatic alignment of parking errors, increasing the difficulty of distance control, and the large size of the coke pushing and coal loading truck, and achieve high-precision alignment. , the effect of enhancing market competitiveness and improving technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

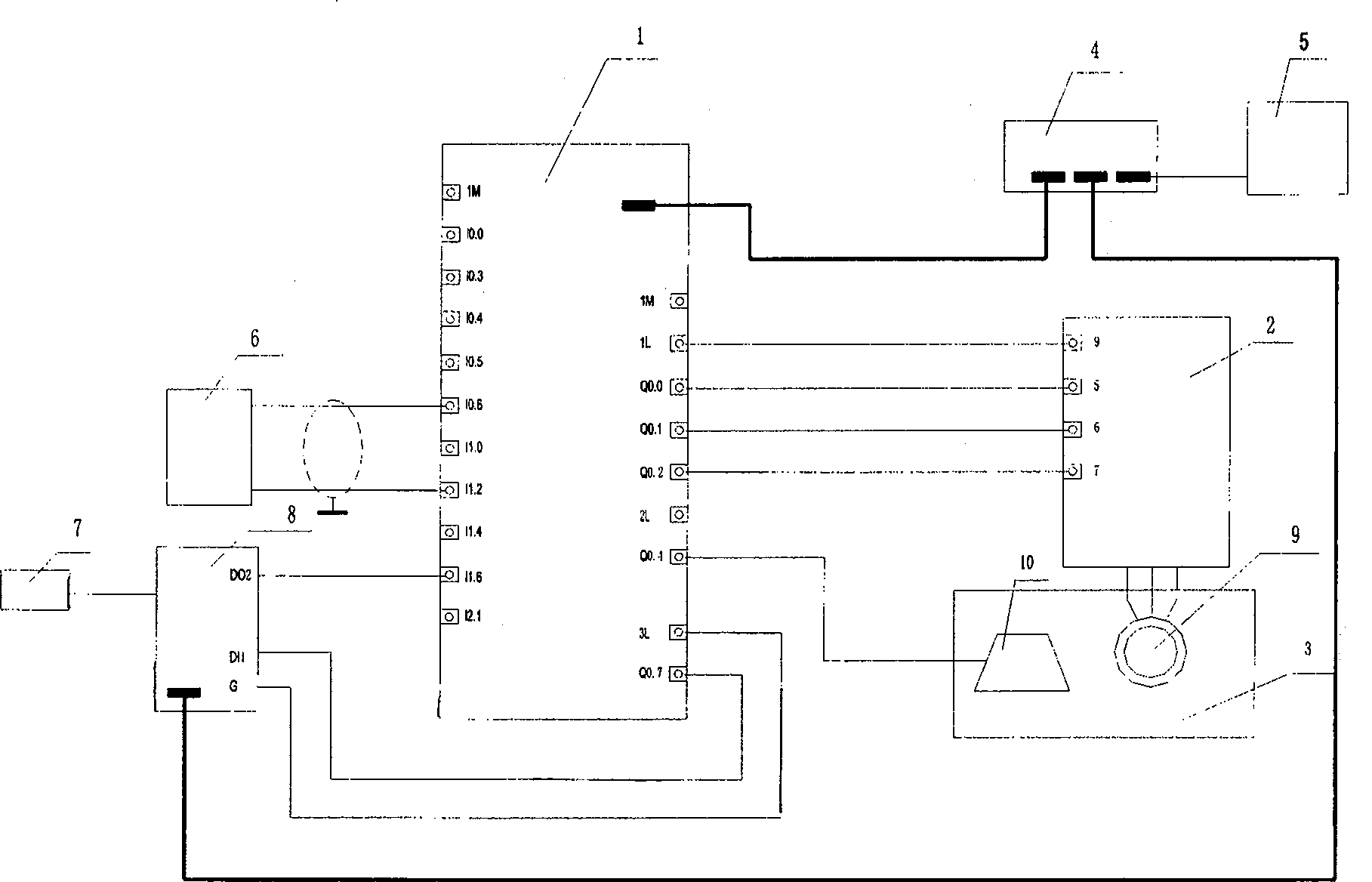

[0030] figure 1 It is a schematic diagram of the hardware circuit of the automatic alignment device of the coke-pushing and coal-loading car based on machine vision technology.

[0031] First of all, the furnace number of each carbonization chamber of the coke oven is uniformly arranged according to natural numbers. For several special alignment actions: "pushing coke", "charging briquettes", and "hanging furnace door" are numbered according to special numbers. All numbers should be unique to avoid confusion. At the same time, there are target furnace number and current furnace number display columns on the display of the man-machine interface, and a target furnace number and current furnace number correction dialog box. During work, if the coke pushing and coal charging truck stops at the center line of a certain carbonization chamber, the display numbers of the target furnace number and the current furnace number will become the same, indicating that the parking position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com