Cutting unit for sewing machine

A sewing machine and cutter technology, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problem that the fixing structure of the lower cutter cannot be fixed reliably, the resistance and stability of the lower cutter are poor, and it is difficult to meet the quality requirements. and other problems, to achieve the effect of increased smoothness, high structural stability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

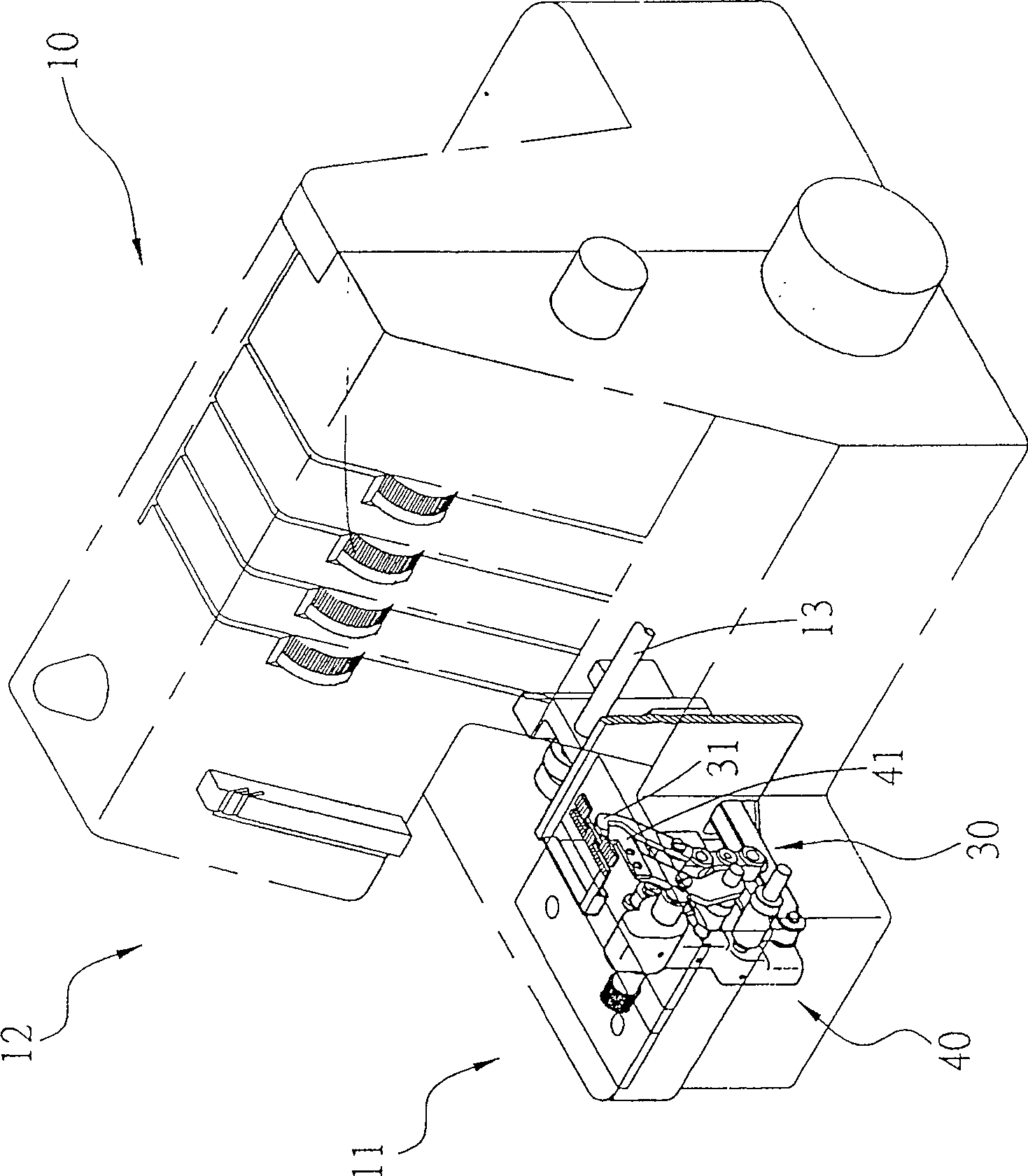

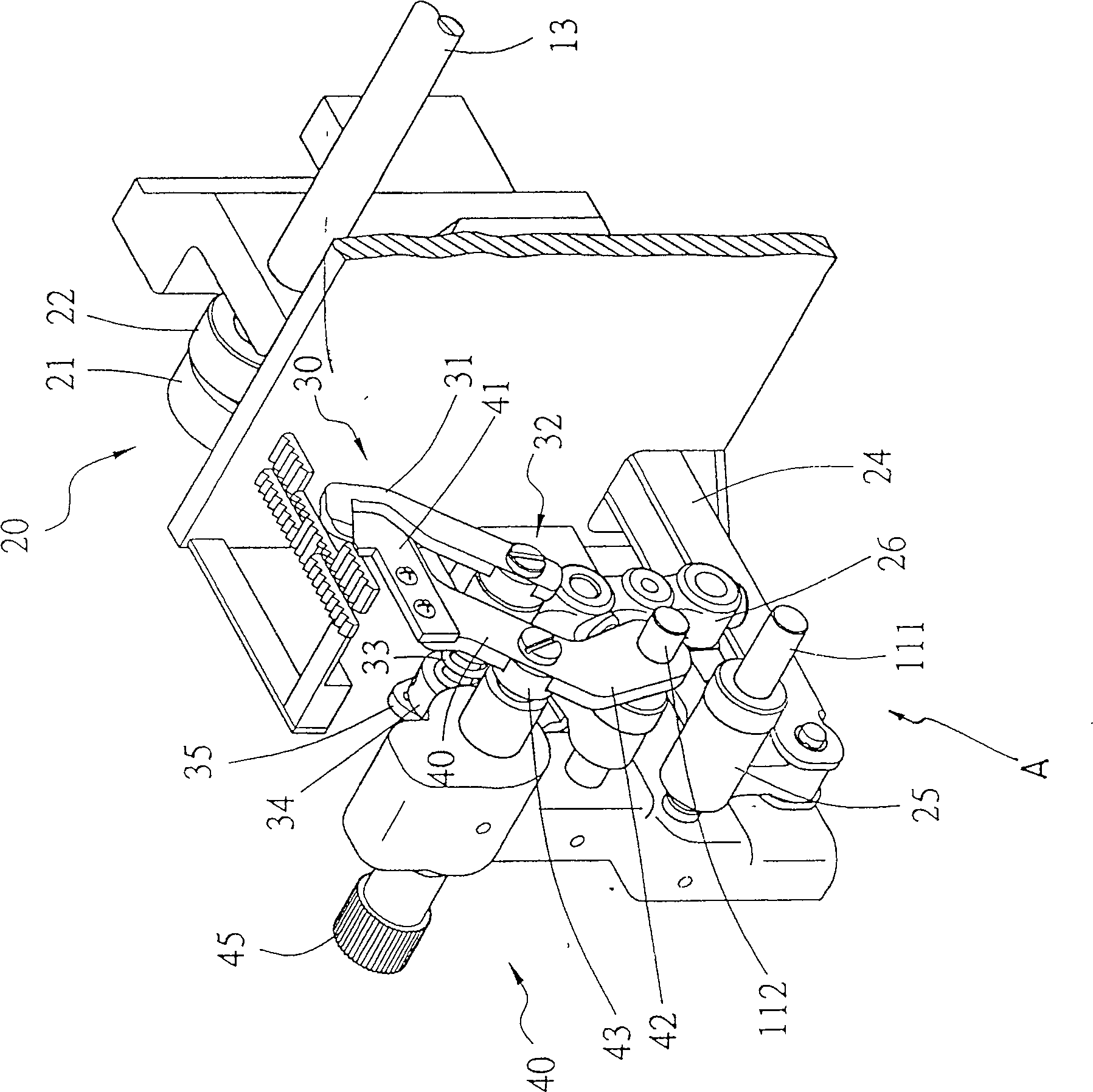

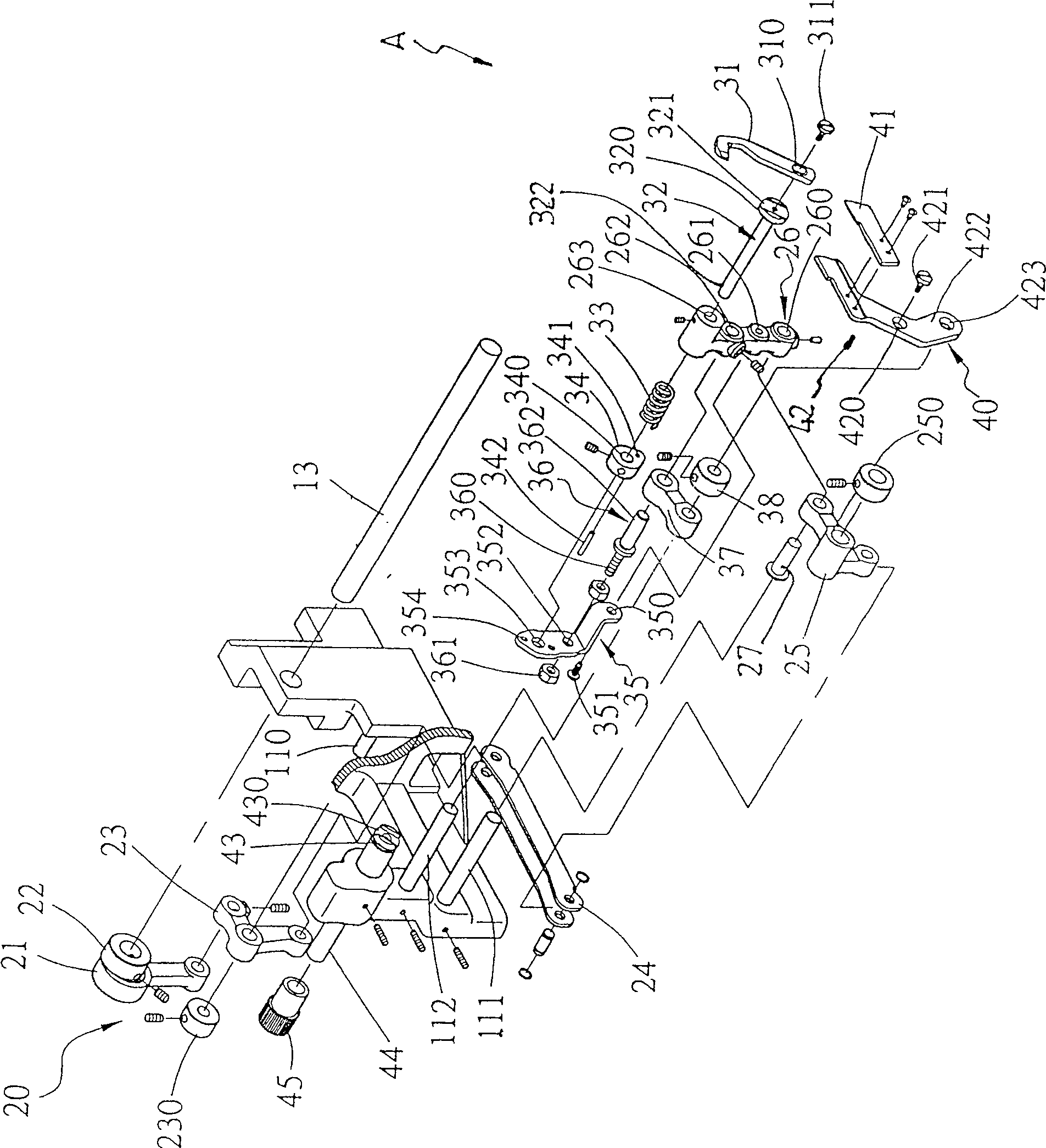

[0064] Please refer to figure 1 , 2, 3, the sewing machine 10 of the present invention, according to the embodiment shown in the accompanying drawings, has a platform-type support 11, the support 11 has a cantilever 12, and the bottom of the cantilever 12 end is provided with a bur. The cutting knife mechanism A for cutting the selvage, the frame 11 is provided with a transmission shaft 13 for power output, cooperates with the upper cutting knife transmission device 20 to drive the upper cutting knife 31 of the cutting knife mechanism A to move; and the cutting knife mechanism A is respectively provided with The upper cutting knife limiting device 30 and the lower cutting knife limiting device 40, the upper cutting knife 31 in the two devices and the lower cutting knife 41 can change their positions and ensure their changed positions; wherein, the present invention The feature is that the upper cutting knife 31 and the lower cutting knife 41 have a more stable function of mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com