Frequency conversion type intellective electromotion unit for valve

A valve electric and intelligent technology, applied in valve device, valve operation/release device, AC motor control and other directions, can solve problems such as water hammer, precision distortion, pipe burst in pipe network system, etc., to improve detection and control accuracy , the effect of reducing volume and cost, and improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

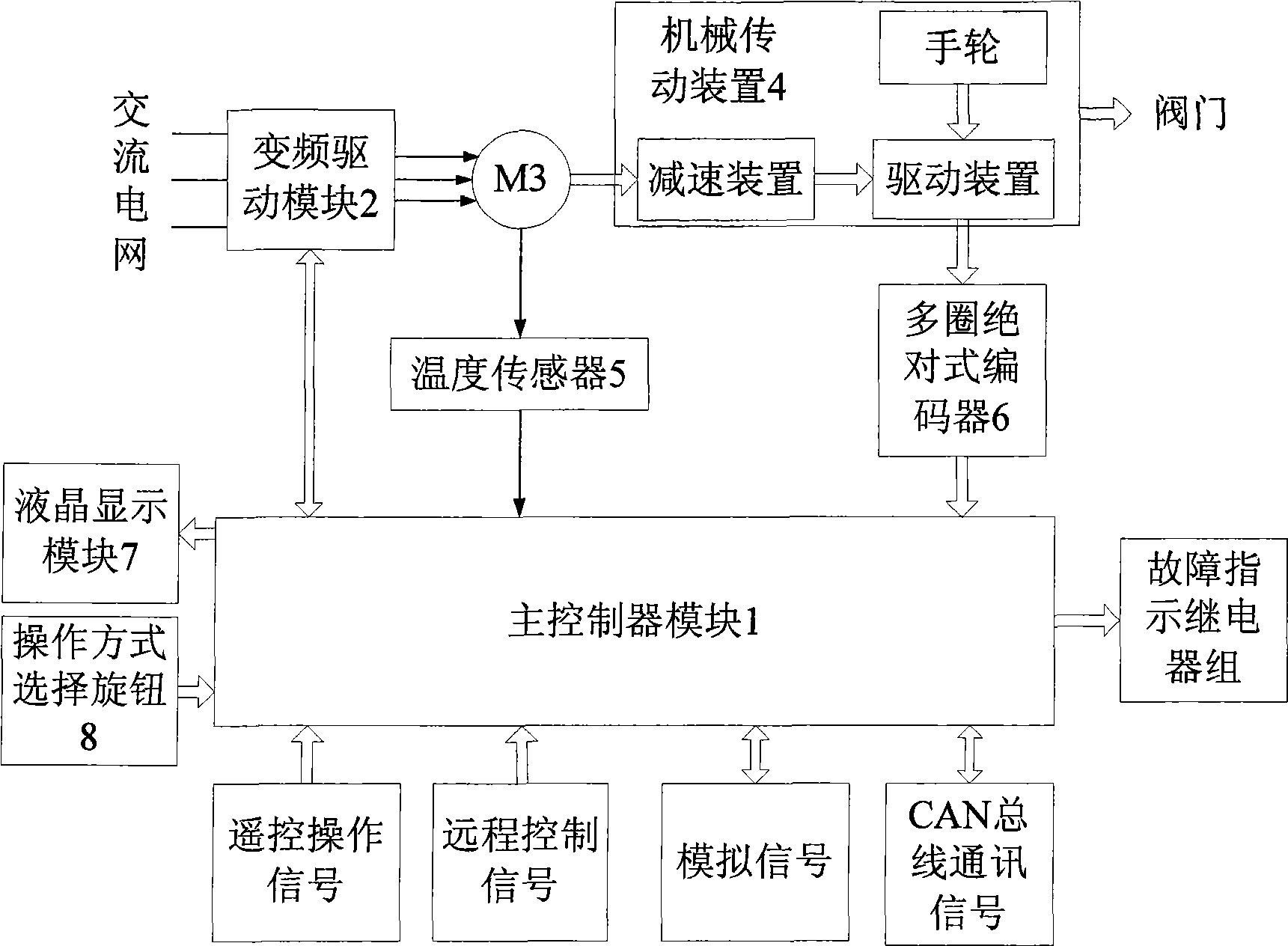

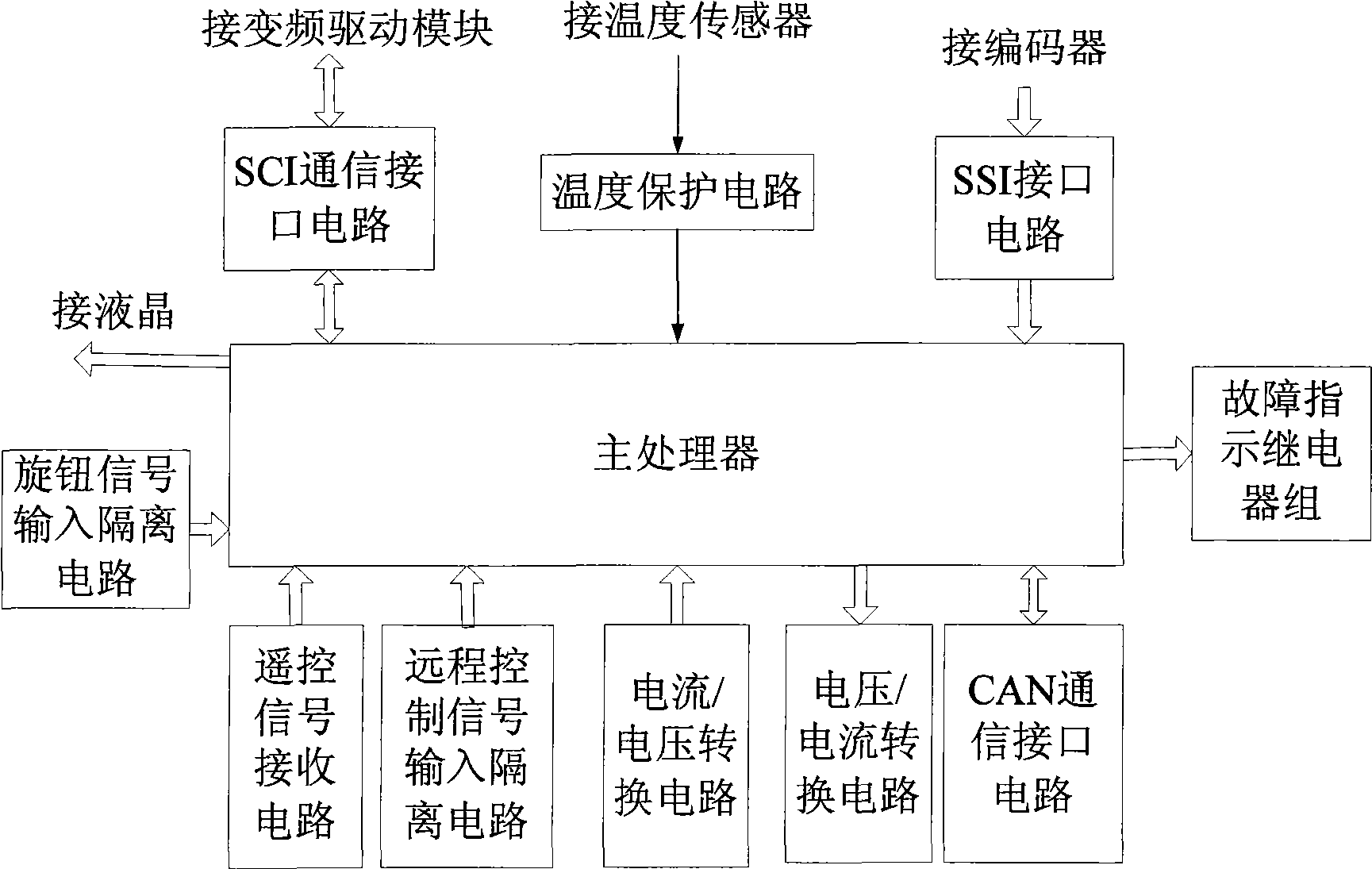

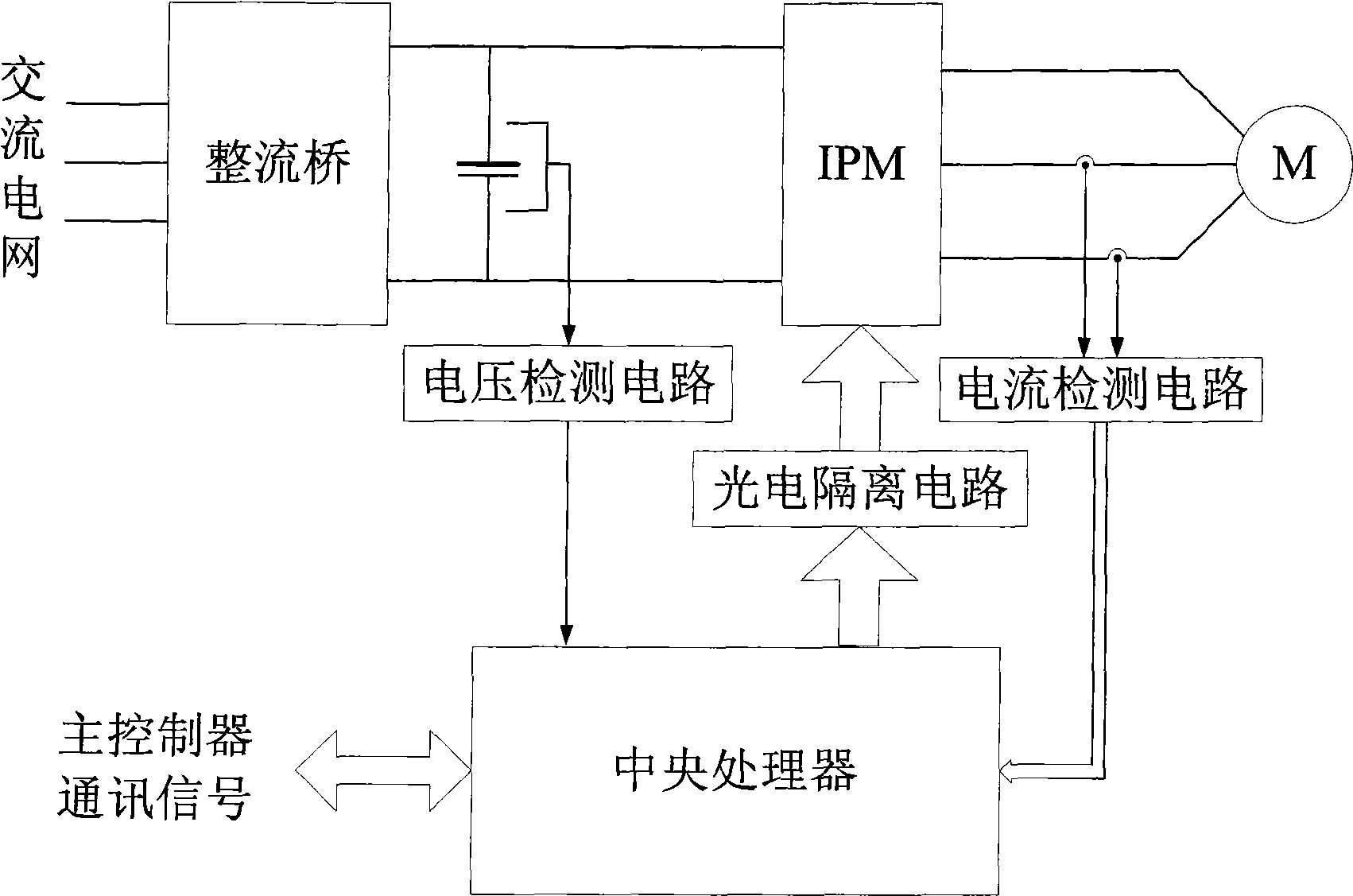

[0038] combine figure 1 , This embodiment includes a main controller module 1, a variable frequency drive module 2, an asynchronous motor 3, a mechanical transmission device 4, a temperature sensor 5, a multi-turn absolute encoder 6, a liquid crystal display 7 and an operation mode selection knob 8.

[0039] 1. The mechanical part of the frequency conversion intelligent valve electric device:

[0040] The mechanical transmission device 4 still adopts the mechanical part of the original ordinary valve electric device, the difference is that the torque detection and the valve opening detection of the original mechanical part are cancelled, and only the manual electric conversion mechanism is retained. , Reduction mechanism, and the main drive output set. In this way, the complexity of the mechanical transmission device is effectively reduced, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com