Workstation for welding mould cooling apparatus

A cooling device and workbench technology, applied in foundry equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of increased labor intensity of operators, affecting the reasonable placement of equipment, and reducing production efficiency, and meet the requirements of the use environment. The effect of reducing and reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

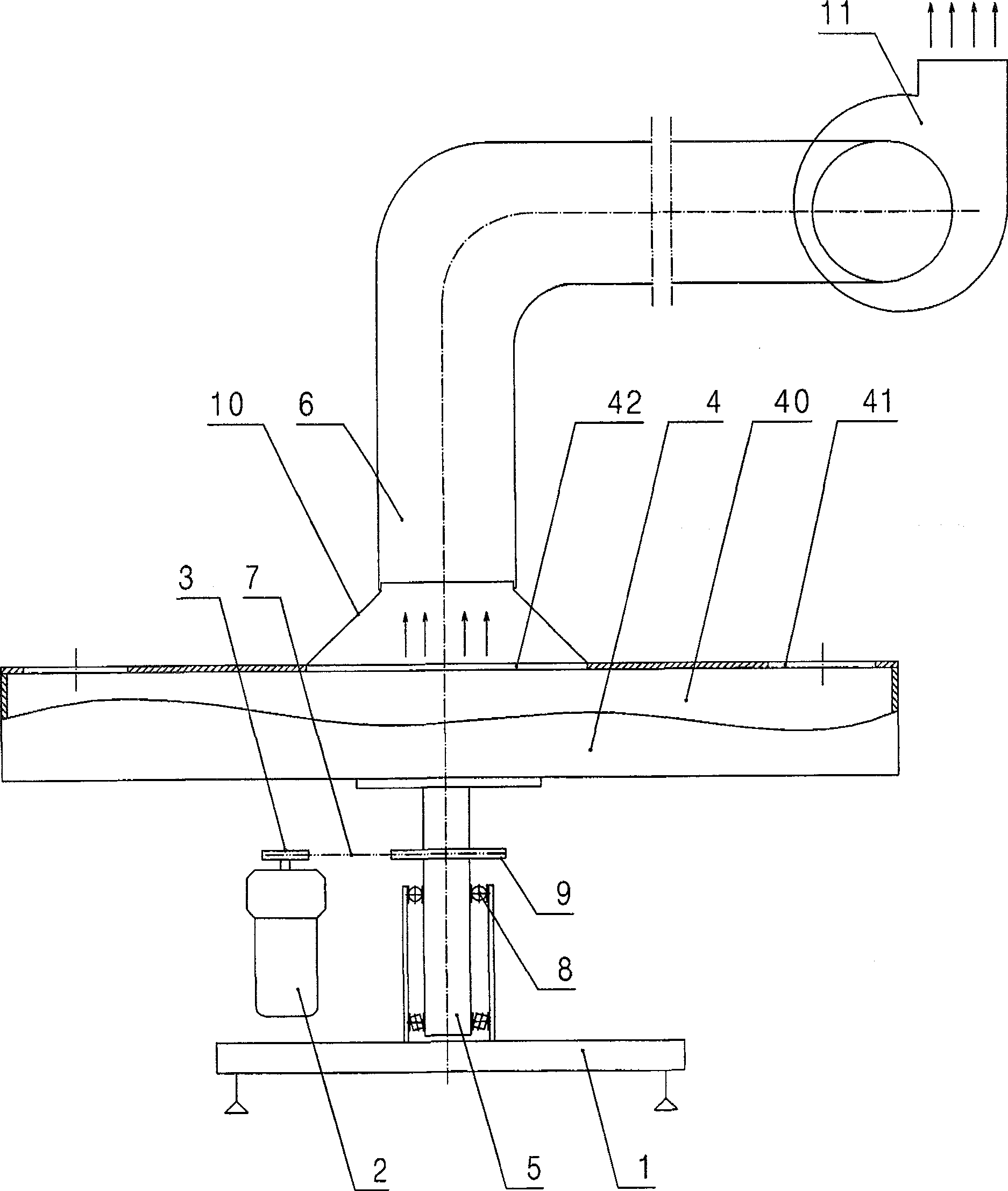

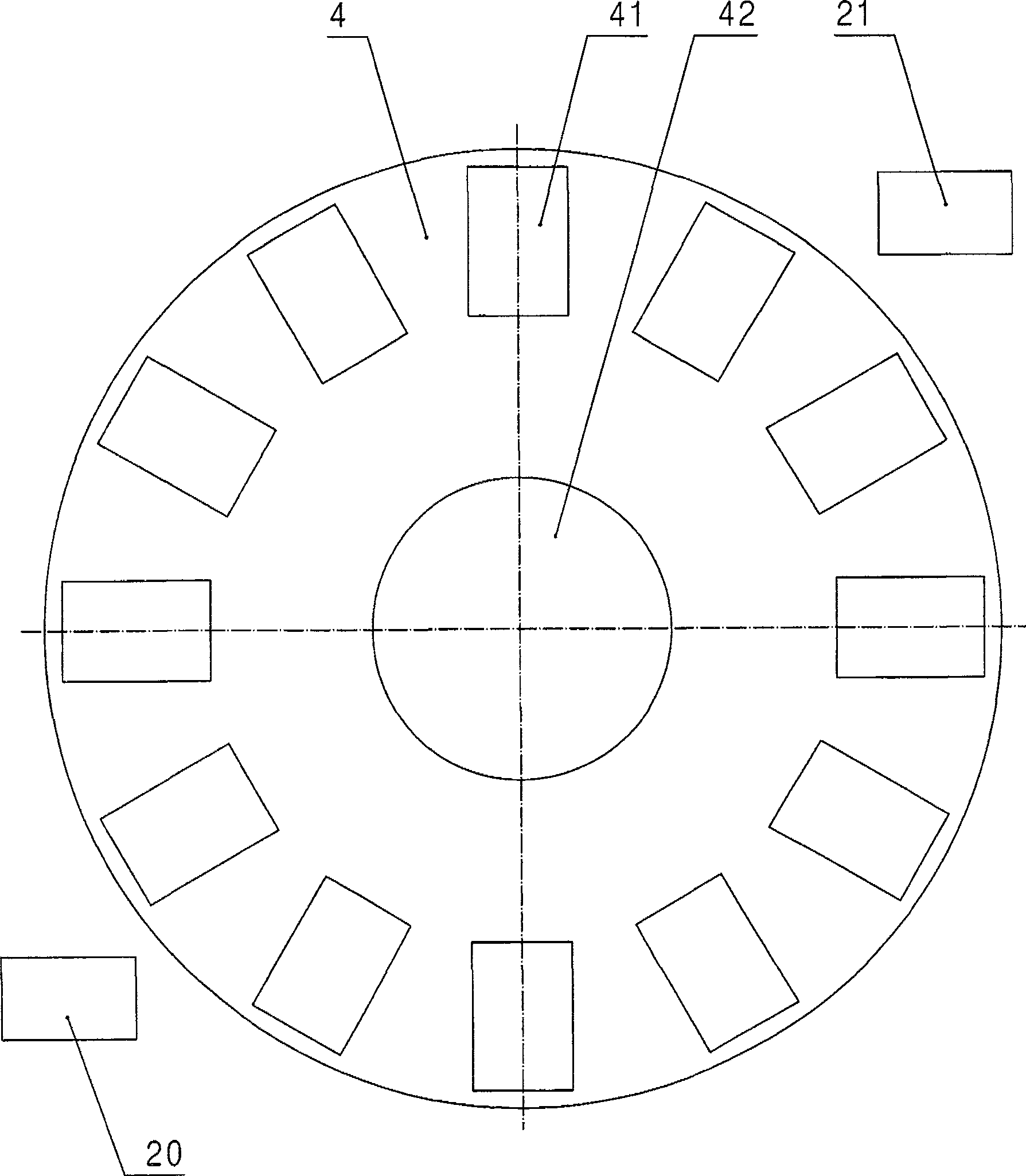

[0011] like figure 1 As shown, the workbench used in the casting and welding mold cooling device according to the present invention includes: a base 1 and a disc-shaped operation box 4, the operation box 4 is a hollow structure, and a built-in exhaust chamber 40, in the operation box 4 The top plate is provided with the exhaust port 42 that communicates with the exhaust cavity 40 and twelve vents 41 for shelving the casting and welding mold, wherein: the exhaust port 42 is located at the center of the top plate of the operation box 4, and on the top plate of the operation box 4 A fairing 10 is arranged above the air outlet 40, a main shaft 5 is arranged on the bottom plate of the operation box 4, and the main shaft 5 is movably supported on the base 1 through the bearing 8; a cycloid reducer is also arranged in the base 1 2——Consists of a motor and a reducer. The output shaft of the cycloidal reducer 2 is provided with a driving sprocket 3, and the main shaft 5 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com