Semiconductor device having IGBT and diode

A diode and semiconductor technology, applied in the field of semiconductor devices, can solve the problems of device 91 damage, breakdown energy reduction, small surge withstand voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

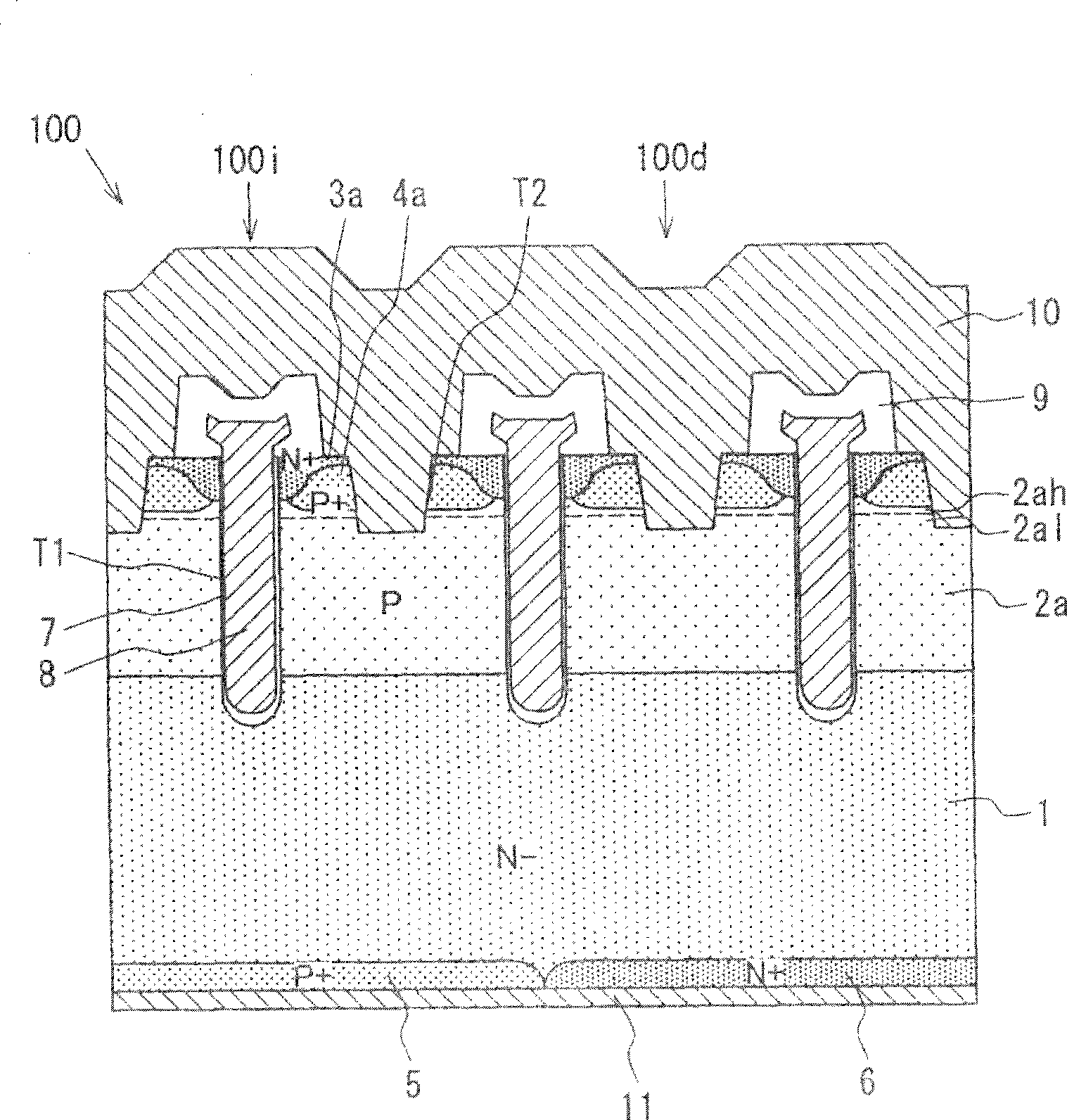

[0037] figure 1 A semiconductor device 100 according to a preferred embodiment is shown. The device 100 includes an IGBT cell 100i and a diode cell 100d formed in the same substrate 1 . Device 100 includes a N - Conductive type semiconductor substrate 1 . The P conductive type layer 2a is formed on the main surface of the substrate 1, and the impurity concentration of the P conductive type region 2a gradually decreases from the surface portion to the inner portion. N on the main surface side with high impurity concentration + Conductivity type region 3a (ie, main N region) and P on the main surface side with high impurity concentration + The conductivity type region 4a (ie, the main P region) is formed on the surface portion of the P conductivity type region 2a. The main P region 4a is formed by the diffusion method so that the main P region 4a does not reach the PN junction between the P conductive type region 2a and the main N region 3a. The main P region 4a is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com