Plasma fuel cell

A fuel cell and plasma technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor start-up performance and high cost of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

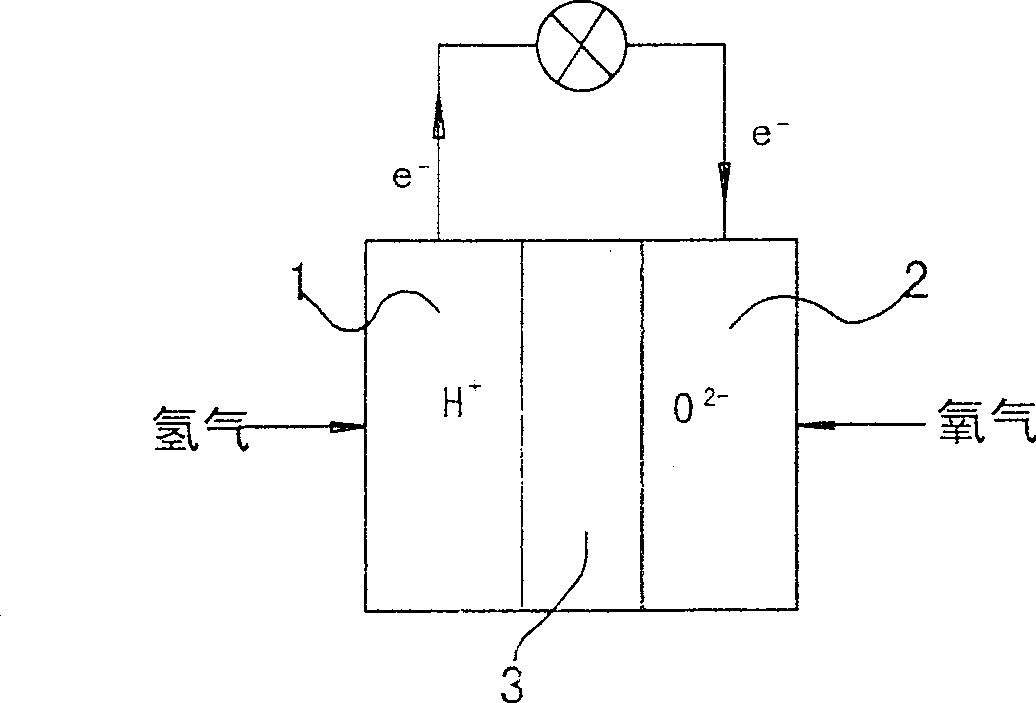

[0018] figure 1 Shown is the basic structural diagram of the existing fuel cell, the electrolyte 3 is between the left porous electrode 1 and the right porous electrode 2, and the left porous electrode 1 and the right porous electrode 2 are respectively connected as an anode and a cathode to form an output circuit; in addition, the electrodes The structure is also different, and the manufacturing process of some electrodes is very complicated. However, their basic principles are common.

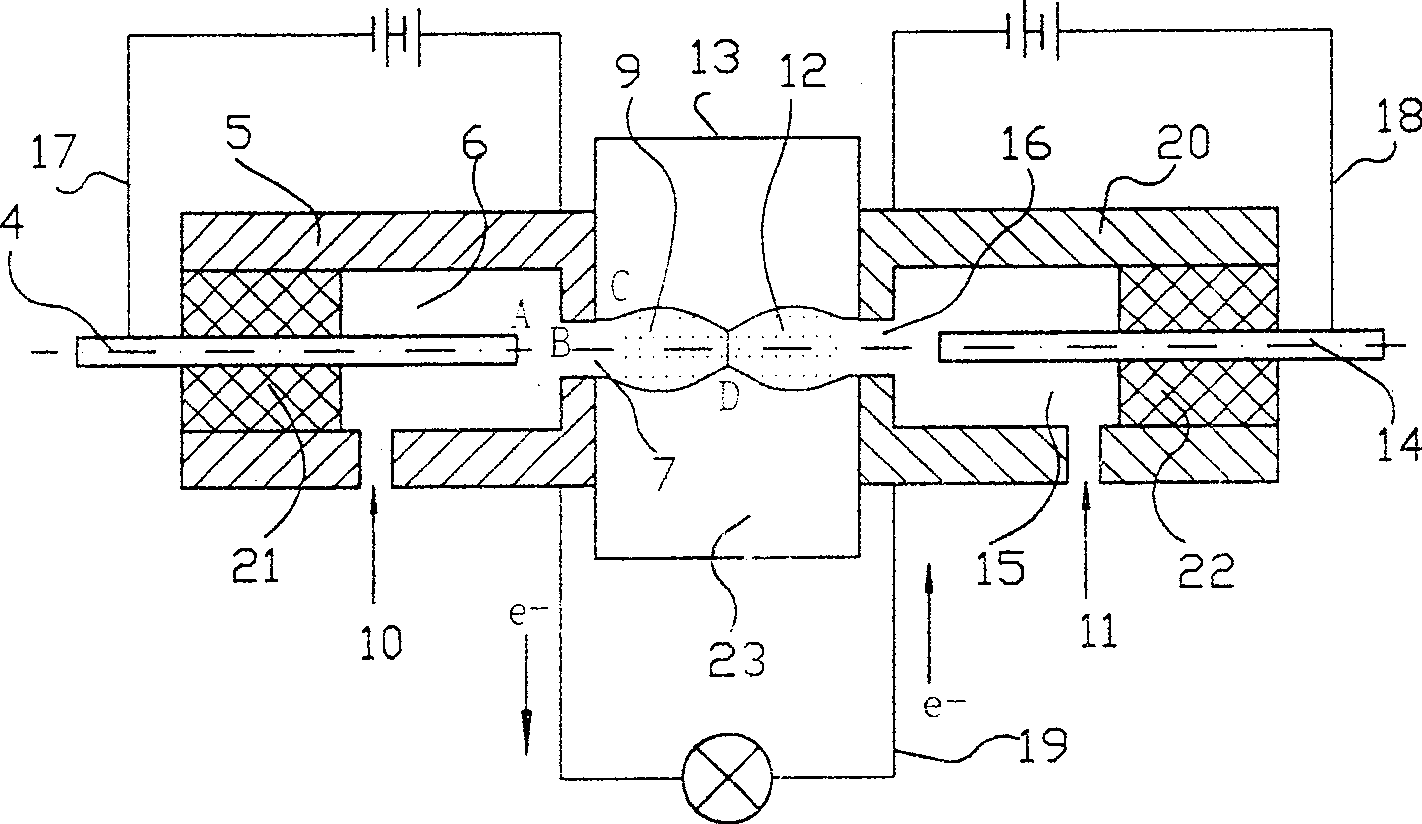

[0019] exist figure 2 Among them, the left plasma gun is composed of the left center electrode 4 and the left gun cavity wall 5. The left center electrode 4 and the left gun cavity wall 5 are separated by an insulator 21. The left gun cavity wall 5 is another electrode of the plasma gun. The left center There is also an inner cavity 6 between the electrode 4, the insulator 21 and the left gun cavity wall 5, on which a hydrogen gas inlet 10 and an injection hole 7 are arranged. The right s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap