Valve and method for producing a valve

A valve seat and valve body technology, which is applied in the field of valve and valve manufacturing, can solve the problems of dirt particles polluting the valve seat, the valve seat is not sealed, and the valve seat is not sealed, and achieves the effect of reducing the risk of polluting the valve seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

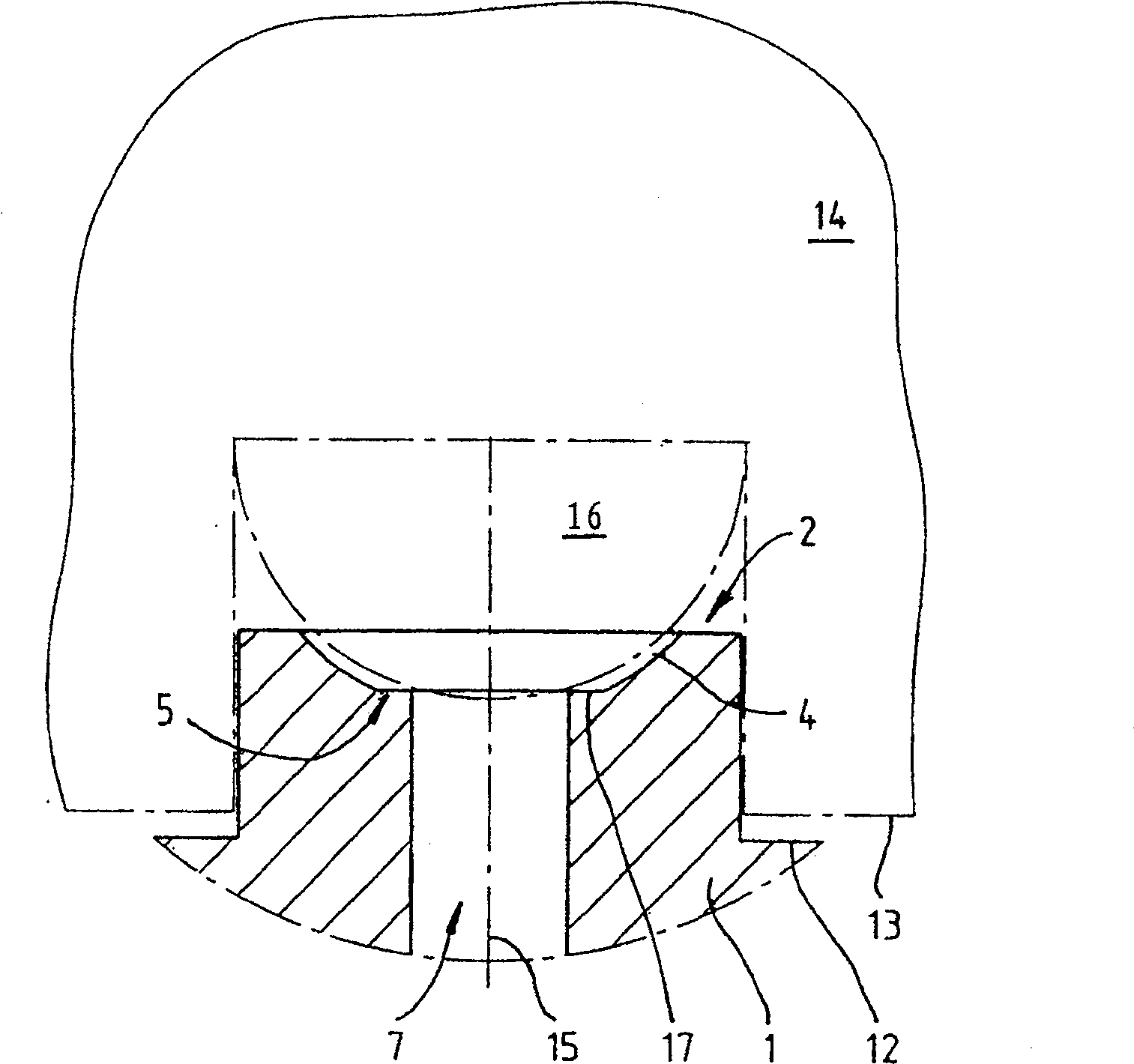

[0033] figure 1 A detail of a pole shoe 1 with a valve seat 2 and a stamping element 16 is schematically shown in . Shown here is the state of the valve seat 2 immediately before or during the stamping process. The recess 4 of a pole piece 1 or valve seat element 1 is preferably produced by turning before stamping, in which case a bead or annular plate 5 with a stamping surface 17 is formed.

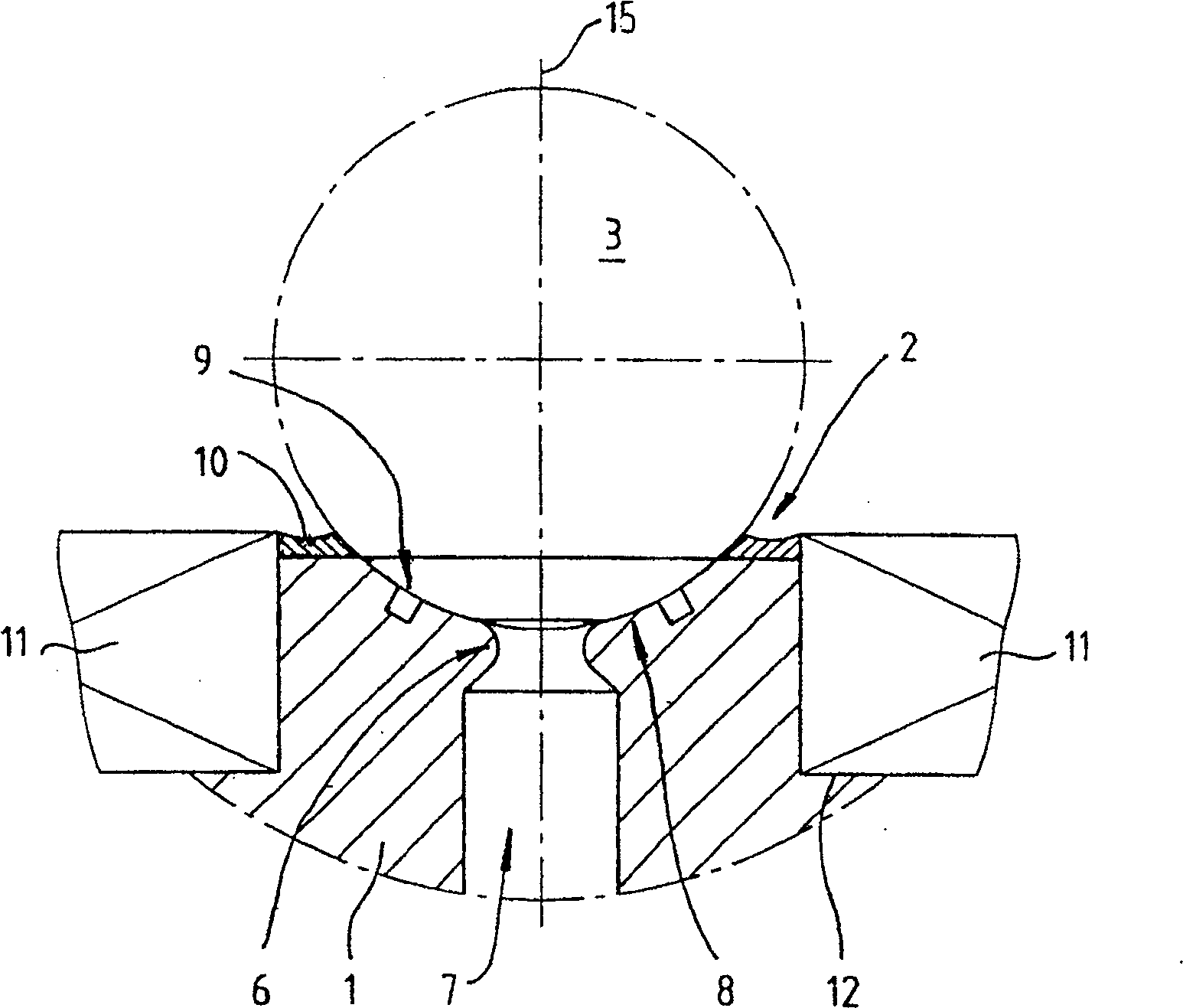

[0034] exist figure 2 The valve seat 2 after the stamping process is schematically shown in . A deformation 6 of the pole piece 1 is produced by the embossing from the projection or the annular plate 5 . It can be seen from the figure that the deformed portion 6 narrows or inflates a valve hole 7 .

[0035] Furthermore, a sealing surface 8 is formed by stamping the valve seat 2 . The sealing surface 8 forms the contact surface between the valve body 3 and the pole piece 1 . The punching is made into a spherical ring as the sealing surface 8 , and the sealing surface has high preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com