Vacuum load switch

A vacuum load and switch technology, applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of lowering the protection level of switch cabinets, assembly difficulties, and non-compliance with environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

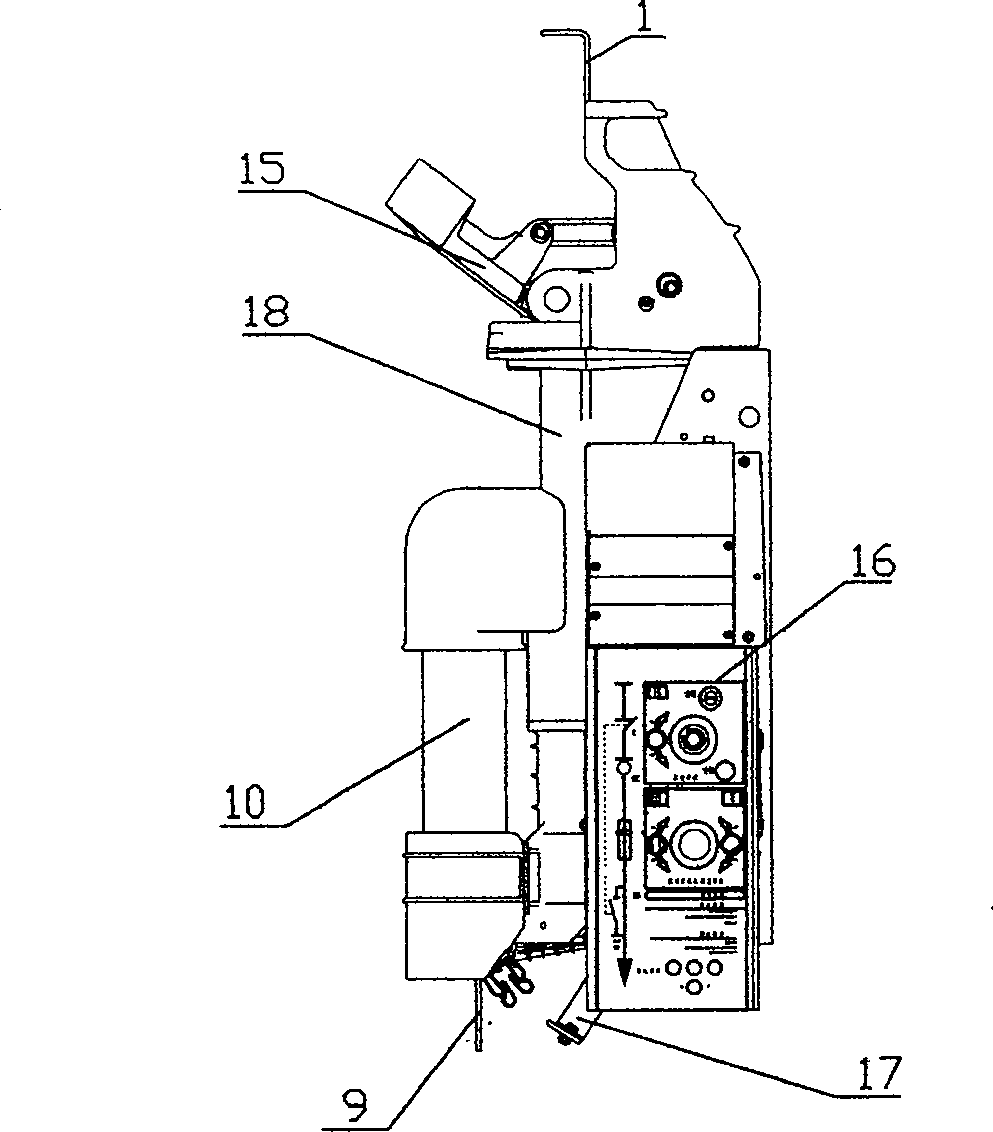

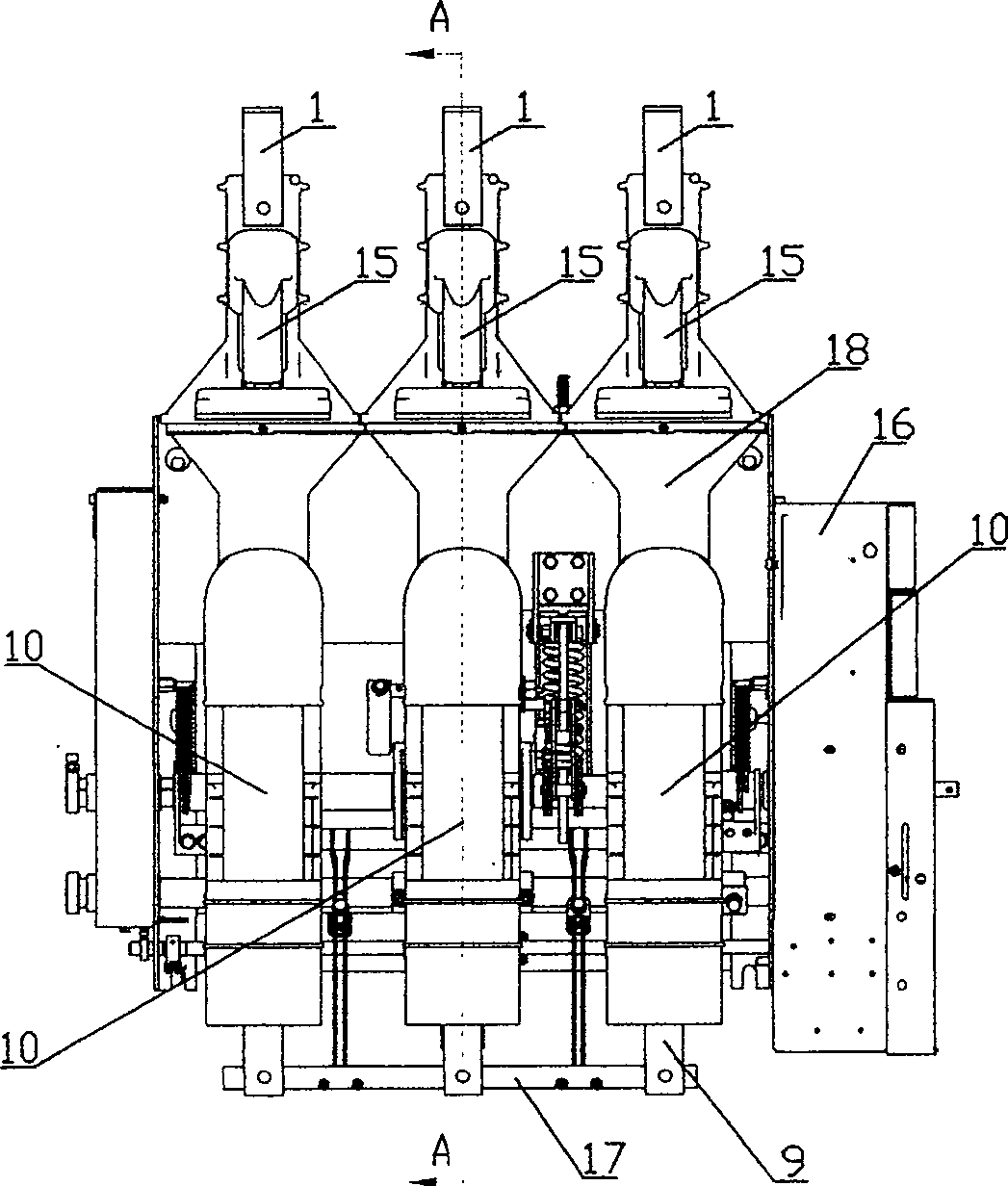

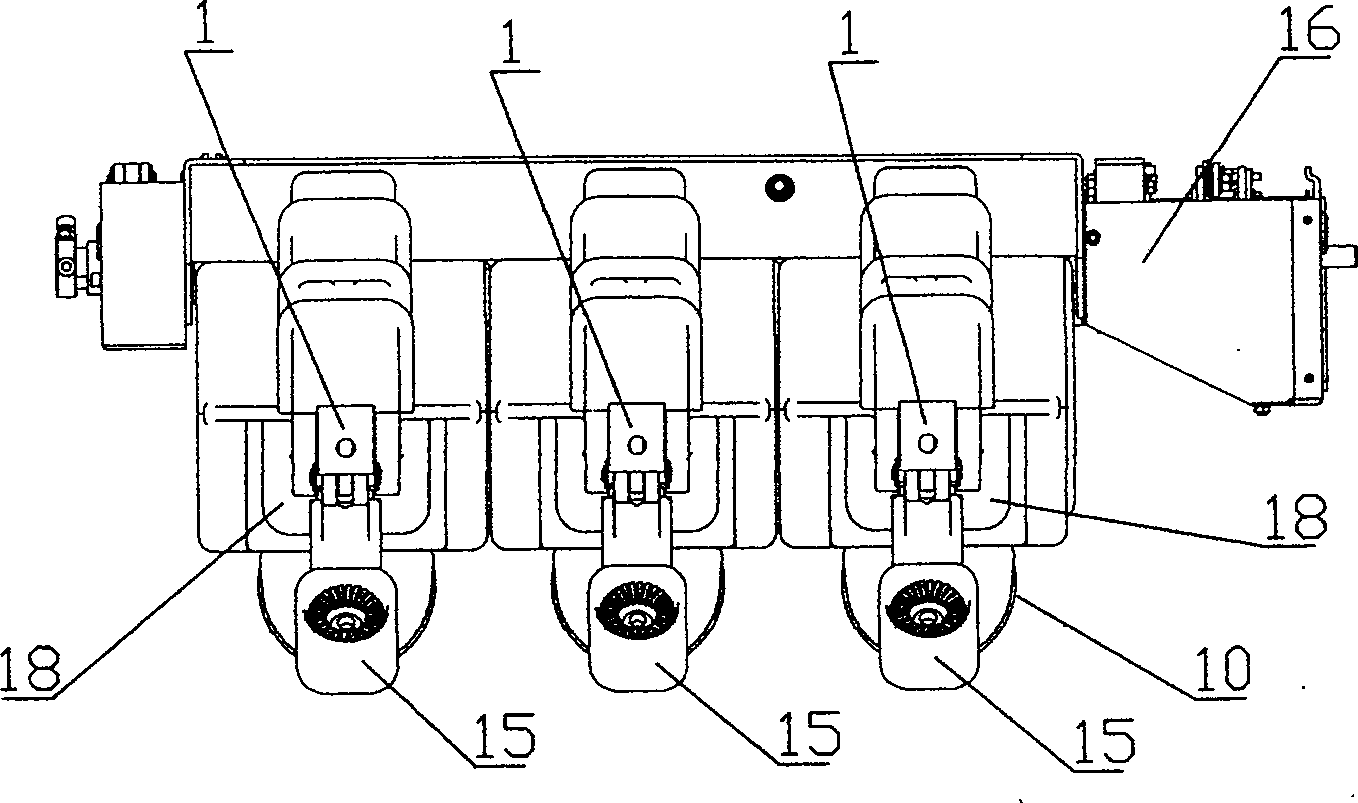

[0017] like figure 1 , 2 , 3, 4, and 5, a vacuum load switch of the present invention includes an upper outlet line 1 on a knife switch, an isolation knife switch 15, an isolation knife seat 13, a vacuum interrupter 5, a lower moving contact 11, and a lower outlet seat 12. Cable outlet plate 9, isolation knife insulation pull rod assembly 4, arc extinguishing chamber insulation pull rod assembly 8, operating mechanism 16 and grounding device 17, isolation knife switch 15 is connected in series with vacuum interrupter 5, isolation knife insulation pull rod assembly 4 and extinguishing The arc chamber insulation pull rod assembly 8 is connected to the operating mechanism 16 by transmission, the isolation knife seat 13, the vacuum interrupter 5 and the lower outlet seat 12 are solidly sealed together, and a fuse is connected in series between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com