Film bulk acoustic-wave resonator and method for manufacturing the same

A technology of piezoelectric resonators and manufacturing methods, applied in the direction of electrical components, impedance networks, etc., can solve the problems of longer processing time, shift of resonance frequency, deterioration of resonance, etc., and achieve the effect of easy film thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

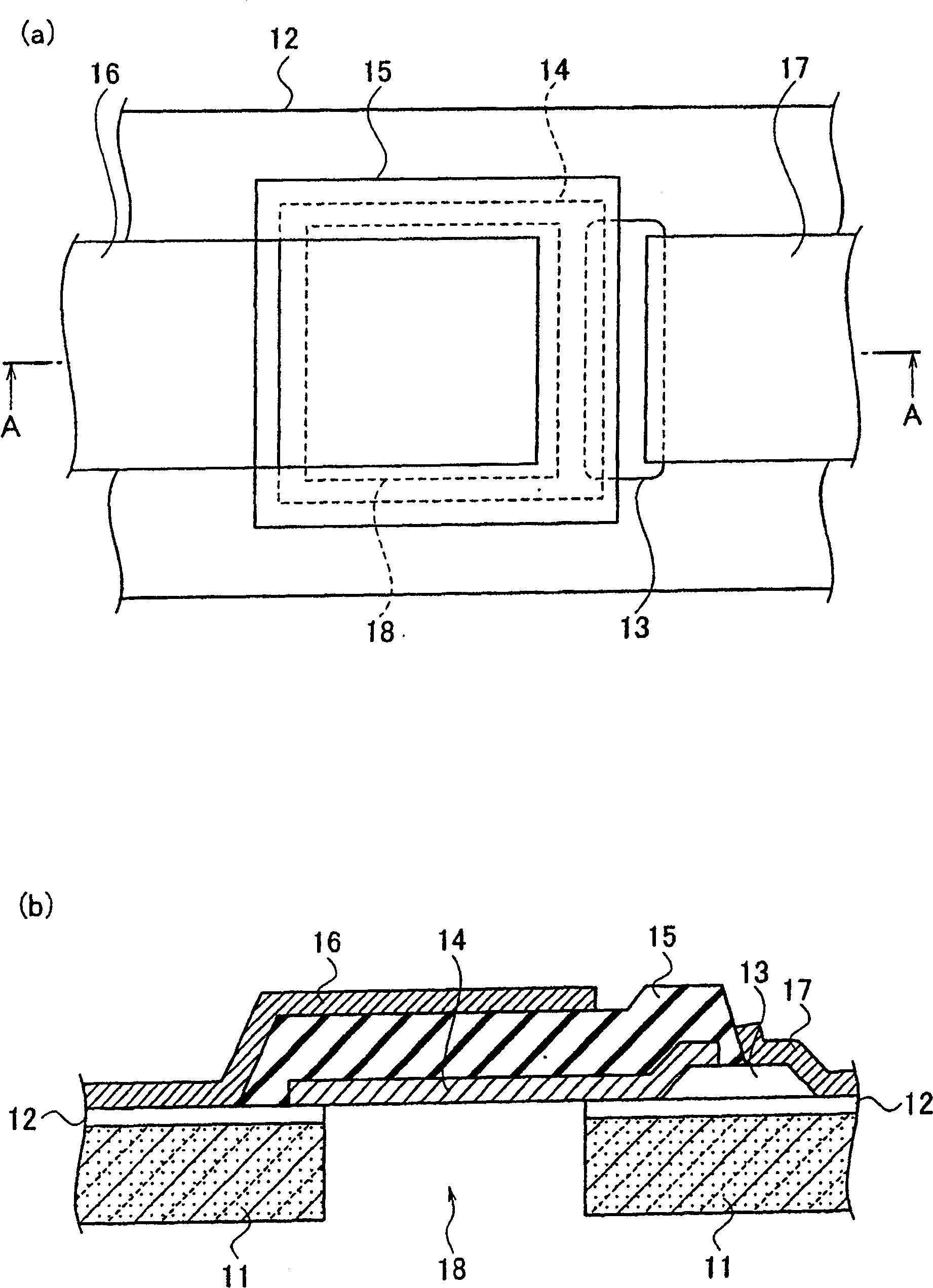

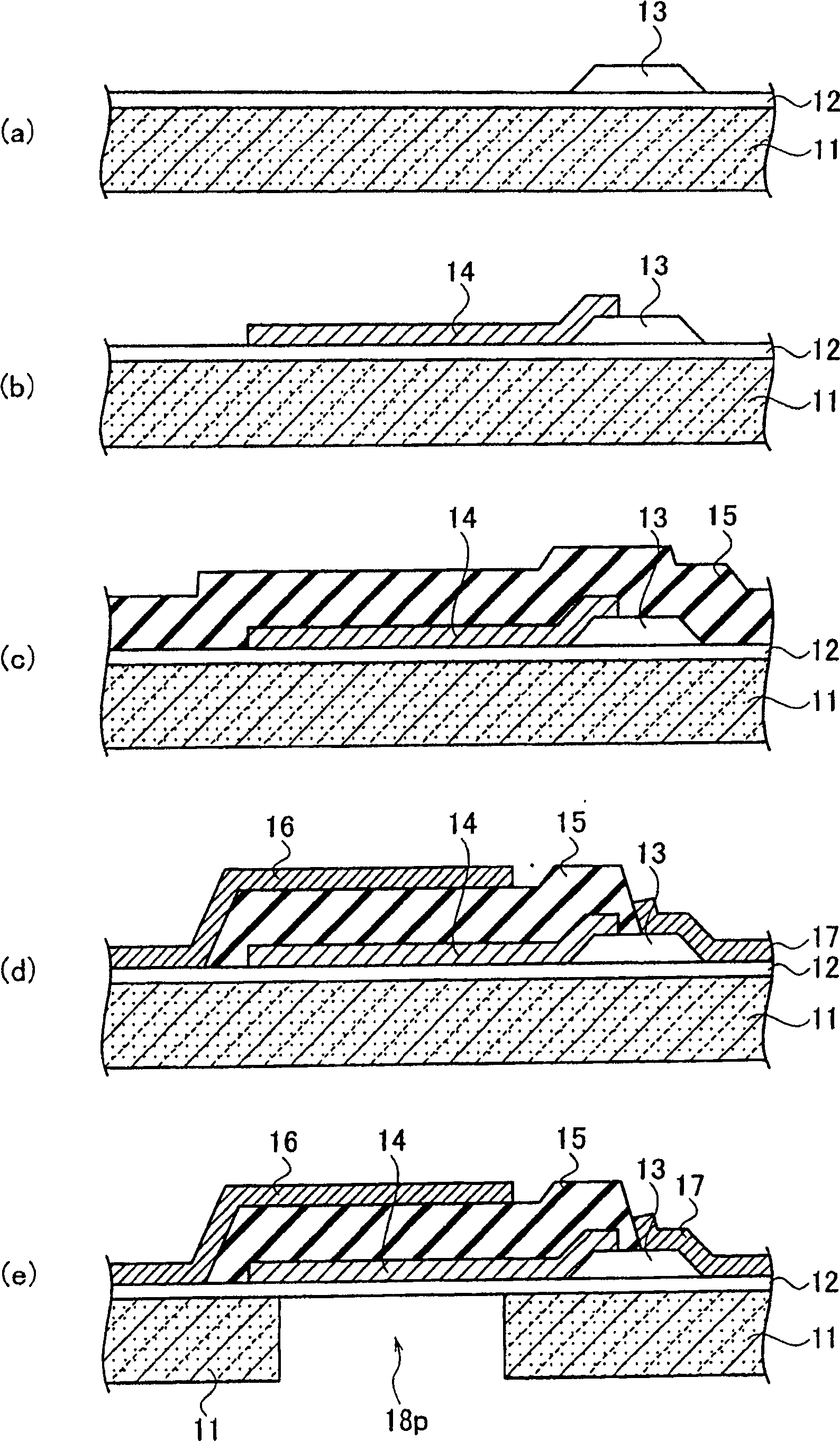

[0053] Such as figure 1 As shown, the thin film piezoelectric resonator according to the first embodiment of the present invention includes: (1) a substrate 11; (2) a lower electrode (14), a part facing the substrate 11 is hollow and mechanically held; (3) The piezoelectric body 15 is arranged on the lower electrode 14 so that it contains all the lower electrodes 14 in the area occupied by itself on a planar figure; (4) the upper electrode 16 is on the piezoelectric body 15; (5) ) The relay electrode 13, between the substrate 11 and the piezoelectric body 15, is located on the boundary of the occupied area of the piezoelectric body 15 on a planar figure, and is connected to the lower electrode 14 inside the occupied area; (6) the lower part The electrode wiring 17 extends from the boundary of the occupied area to the outside, and is connected to the relay electrode 13 . Furthermore, bulk vibration in the thickness direction of the piezoelectric body 15 is utilized.

[0054...

no. 2 Embodiment approach

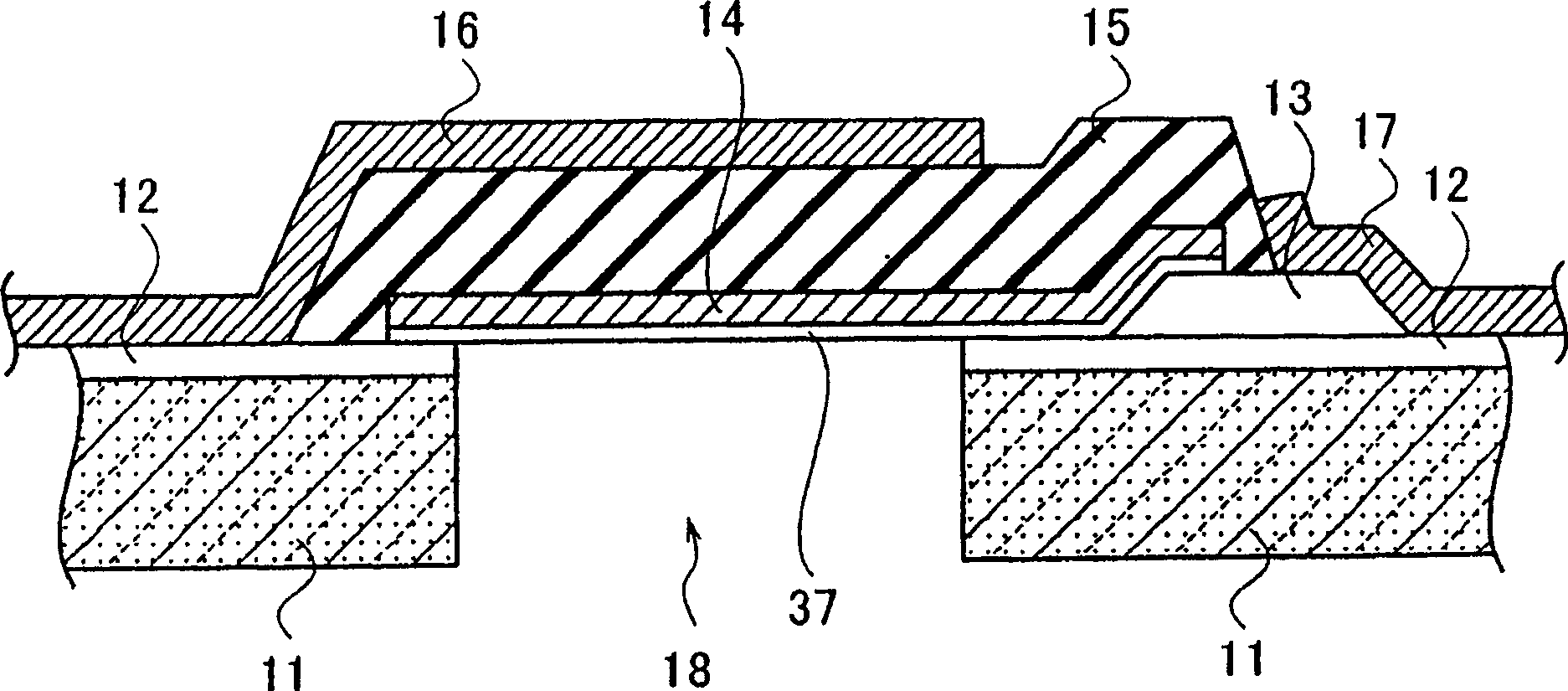

[0089] Such as Figure 10 As shown, the thin film piezoelectric resonator according to the second embodiment of the present invention includes: a substrate 11; an insulating film 12 formed on the substrate 11; a cavity (cavity) 19 passes through the insulating film 12, a part of which is hollow and Mechanically held lower electrode 14; a relay electrode 13 electrically connected to the lower electrode 14, which is partially laminated on one end of the lower electrode 14; formed between the lower electrode 14 and the relay electrode 13 The upper piezoelectric body 15 ; the upper electrode 16 formed on the piezoelectric body 15 ; and the lower electrode wiring 17 electrically connected to the relay electrode 13 . exist Figure 10 Only the sectional view is shown in the figure, and the plane figure is basically the same as figure 1 (a) is the same and the illustration is omitted. However, the piezoelectric body 15 includes all the lower electrodes 14 within the area occupied b...

no. 3 Embodiment approach

[0104] Such as Figure 12 As shown, the thin film piezoelectric resonator according to the third embodiment of the present invention includes: a substrate 11; an insulating film 12 formed on the substrate 11; The relay electrode 23 of the U-shaped groove; the lower electrode 14 formed on the insulating film 12 and the relay electrode 23; the piezoelectric body 15 formed on the lower electrode 14 and the relay electrode 23; An upper electrode 16 formed on the piezoelectric body 15 ; and a lower electrode wiring 17 electrically connected to the relay electrode 23 . exist Figure 12 Only the sectional view is shown in the figure, and the plane figure is basically the same as figure 1 (a) Similarly, illustration is omitted. However, the piezoelectric body 15 includes all the lower electrodes 14 within the area occupied by the piezoelectric body 15 in a plan view. And, with figure 1 The plane figure shown in (a) is the same, the boundary of the occupied area of the piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com