Motor vehicle with carrying goods baseboard structure

A technology for motor vehicles and base plates, which is applied to motor vehicles, vehicles used for freight, and superstructures, etc., and can solve problems such as additional design and processing costs, and unsuitability for light-duty trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

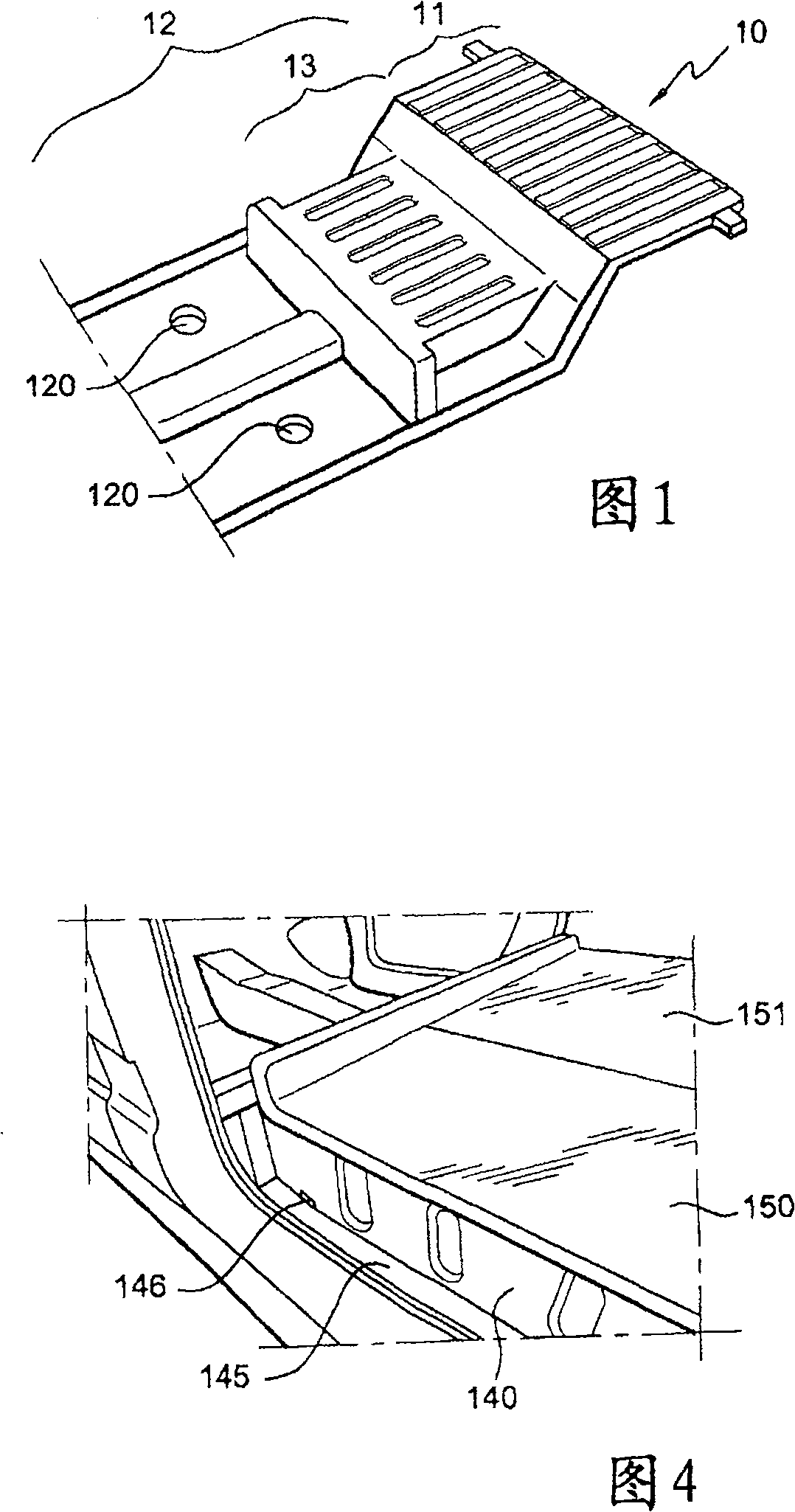

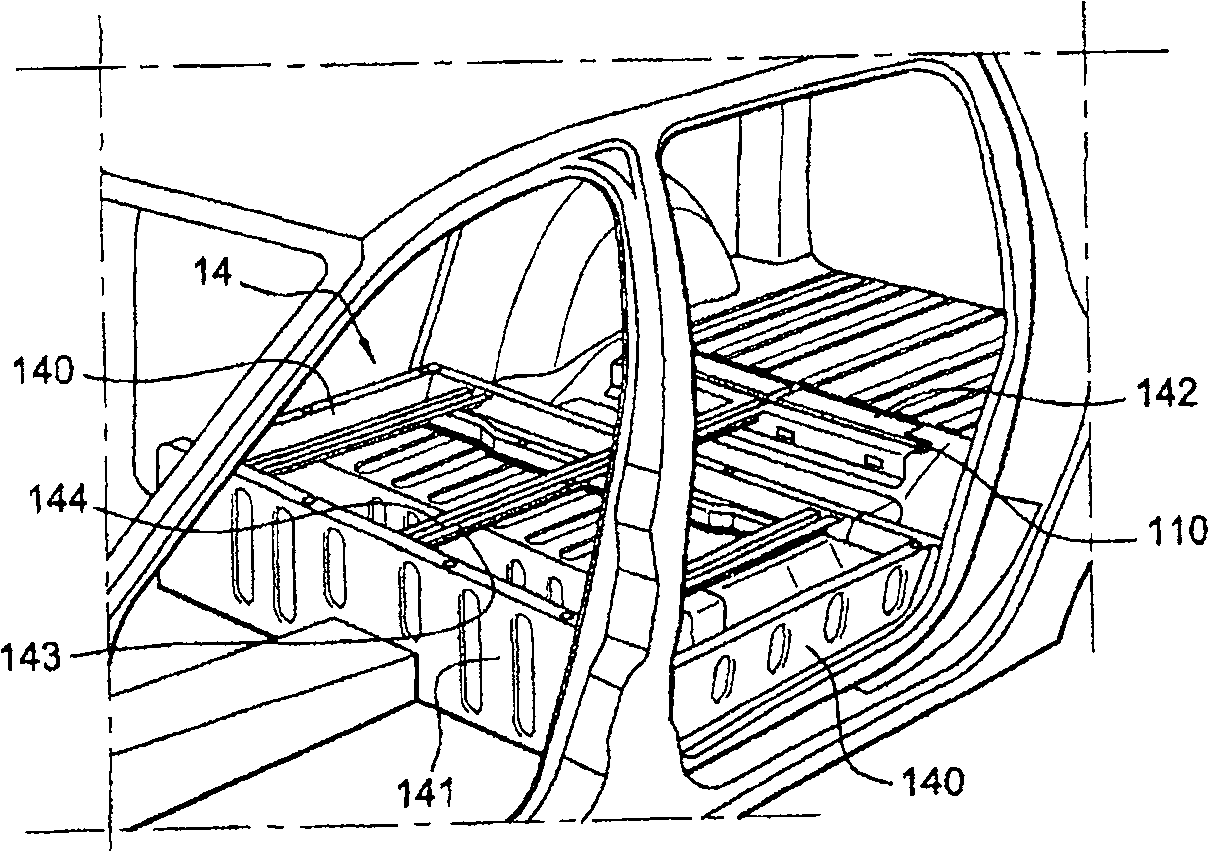

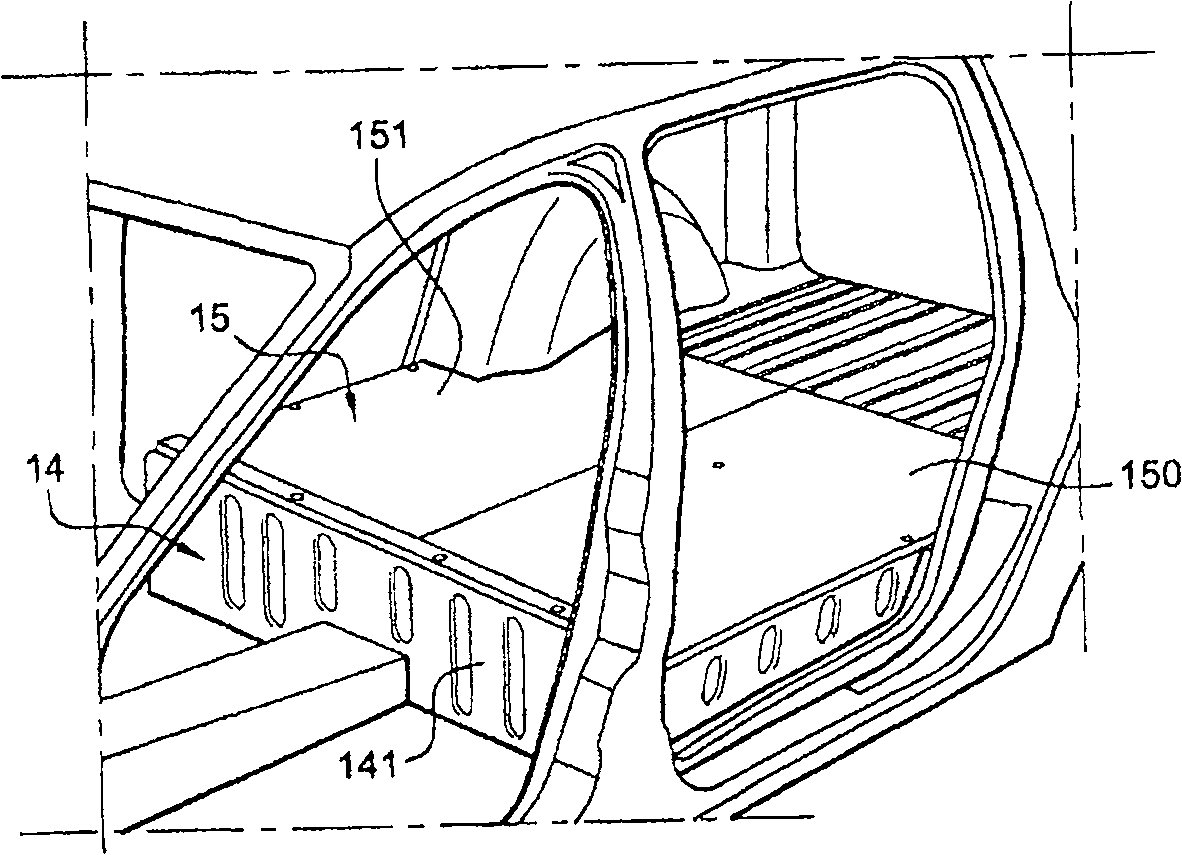

[0024] Figures 1 to 6 The structure of a motor vehicle according to the invention is shown.

[0025] The structure includes a first bottom plate 10 at the lower part, such as figure 1 shown. At the rear, the first base plate 10 comprises a first cargo area 11 having a planar shape. The first load area 11 is adjacent to a lower area 12 for passengers, which is designed to be equipped with one or more rows of seats, not shown. The lower area 12 is designed to accommodate the feet of passengers and is below the level of the first area. The lower region includes a middle region 13 adjacent to the first region 11 . When the vehicle is configured for a passenger car, the central area 13 can accommodate a row of seats.

[0026] Typically, the vehicle's structure is constructed by assembling sheet metal that is extruded and welded together. The floor generally comprises structural elements, such as longitudinal and transverse members, not shown, which support the sheet metal fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com