Integrally-formed vapor chamber and preparation method and application thereof

A vapor chamber and integrated technology, which is applied in the field of integrally formed vapor chamber and its preparation, can solve problems affecting the performance of the vapor chamber, poor sealing performance of the vapor chamber, and reduction of the effective condensation area, so as to improve environmental adaptability ability, reduced weight and thickness, high sealing and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] As an optional embodiment of the present invention, the fluid working medium includes any one or a combination of at least two of deionized water, ethanol or acetone.

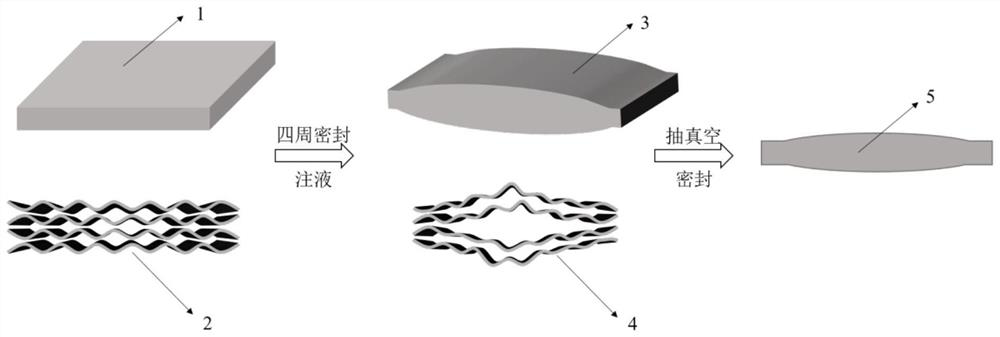

[0044] According to the second aspect of the present invention, there is also provided a method for preparing the above integrally formed vapor chamber, comprising the following steps:

[0045] (a) providing a graphene substrate sheet;

[0046] (b) sealing around the graphene matrix plate;

[0047] Inject the fluid working substance into the interior of the graphene matrix plate through the injection port, and then evacuate the interior of the graphene matrix plate to form a vacuum cavity inside to hold the fluid working substance, and then seal the injection port , forming a graphene plate, thereby obtaining an integrally formed vapor chamber.

[0048] The present invention provides a method for preparing the above-mentioned integrally formed vapor chamber, first sealing the surroundings of the graphe...

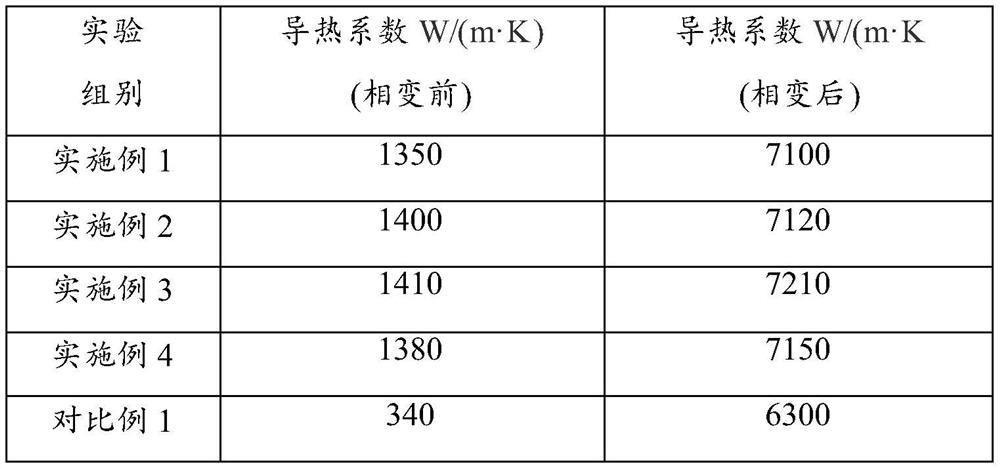

Embodiment 1

[0064] This embodiment provides an integrally formed vapor chamber, including a graphene plate;

[0065] The graphene plate is sealed around, and a vacuum cavity is set inside the graphene plate, and a fluid working medium is contained in the vacuum cavity, and the fluid working medium is deionized water;

[0066] The graphene plate is made by integral molding of the graphene substrate plate.

[0067] The preparation method of the integrally formed vapor chamber provided in this embodiment, the schematic flow chart is as follows figure 1 shown, including the following steps:

[0068] (a) providing a graphene substrate sheet;

[0069] Graphite is oxidized and stripped into graphene oxide by chemical method, and then the graphene oxide is made into a slurry form, and the graphene oxide slurry is made into a graphene oxide plate through a coating machine, and the graphene oxide plate is first carbonized at 1000 °C , and then hot-pressed and reduced at 3000°C to obtain a graphe...

Embodiment 2

[0077] This embodiment provides an integrally formed vapor chamber, the specific structure of which is the same as that of Embodiment 1.

[0078] In the preparation method of the integrally formed vapor chamber provided in this example, except that the thickness of the graphene substrate plate in step (a) is 300 μm, other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com