Method for producing a motor vehicle fixed roof element and fixed roof element

A technology for motor vehicles and components, which is applied to vehicle components, superstructure, and sub-assembly of the superstructure, etc., can solve the problems of the antenna board affecting the appearance, scrap parts, and damage to the antenna board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

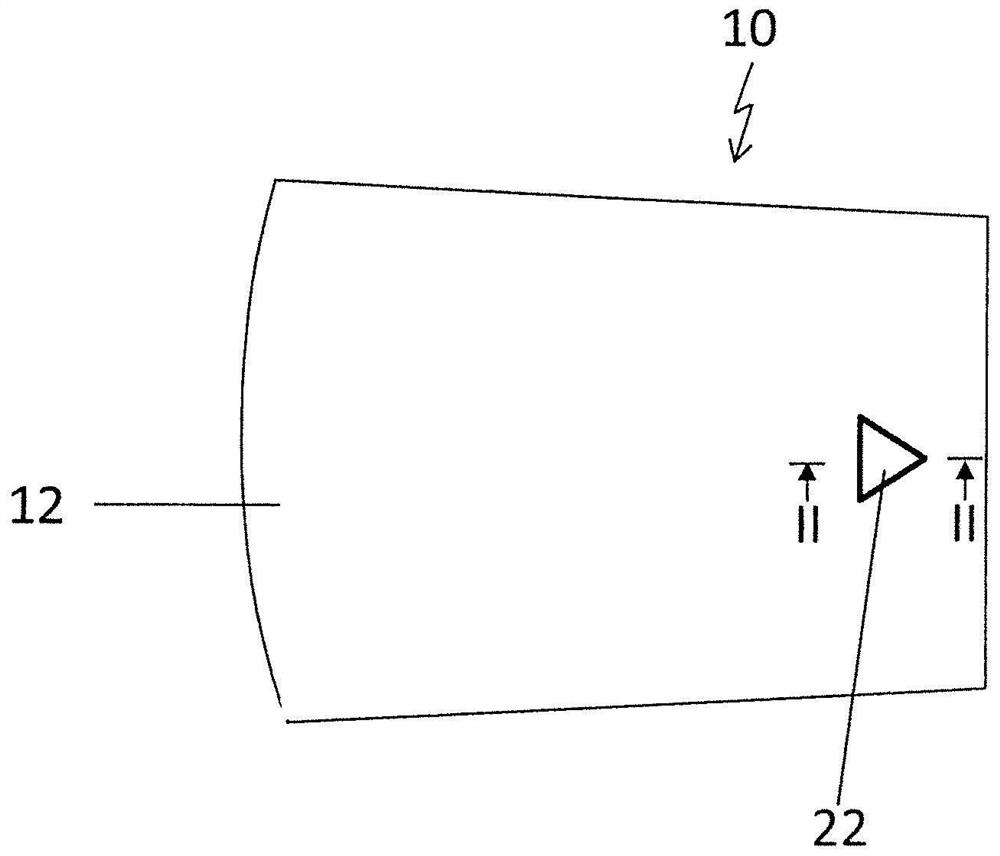

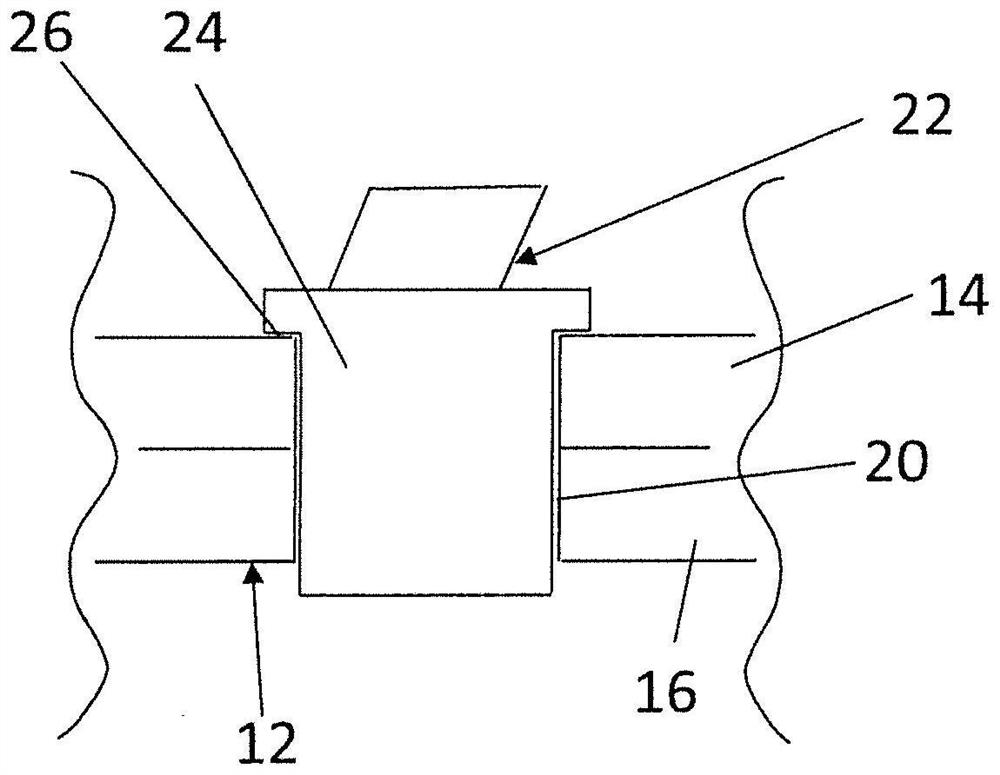

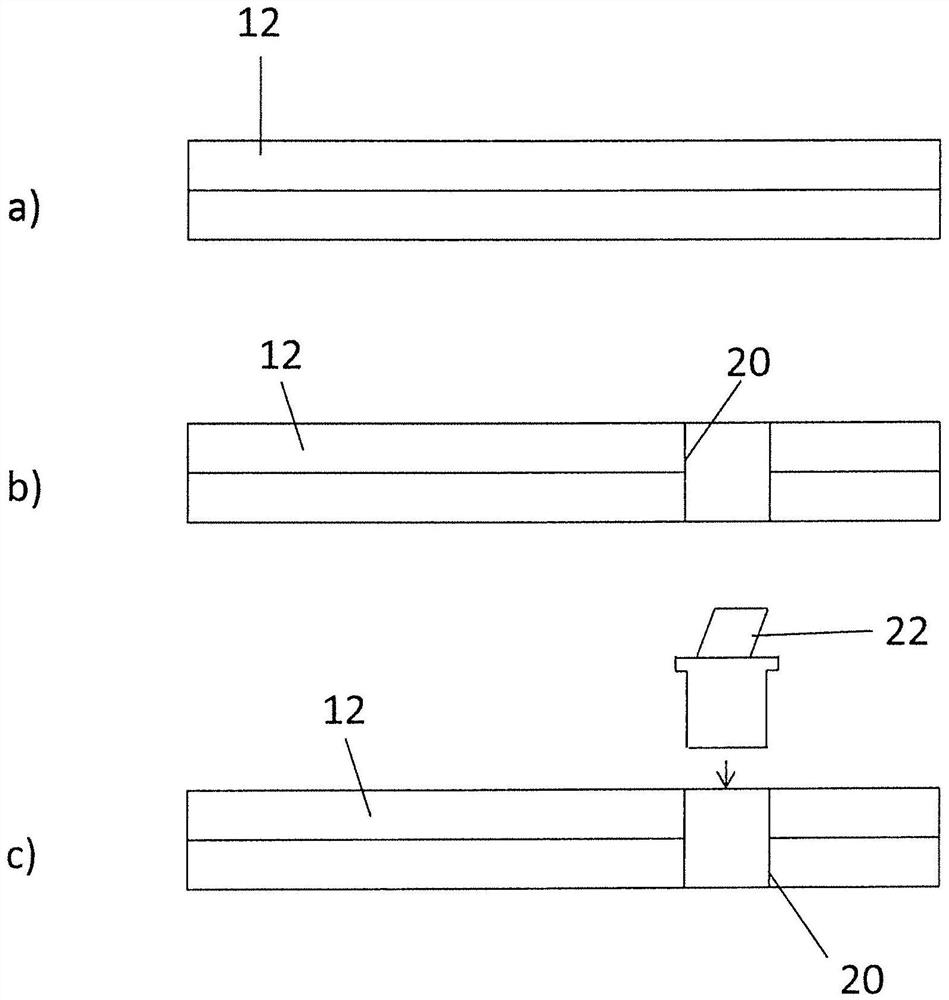

[0025] exist figure 1 with figure 2 10 shows a fixed roof element 10 of a motor vehicle designed as a passenger car, which can be inserted into a roof recess of a motor vehicle body (not shown in detail). The fixed roof element 10 has a contour corresponding to the roof recess with two straight side edges, a straight rear edge and a curved front edge. The mounting of the fixed roof element 10 in the roof recess takes place, for example, by means of an adhesive tape.

[0026] The fixed roof element 10 comprises a glass compound 12 which is laminated safety glass (VSG) and which is curved both in the longitudinal direction of the roof and also in the transverse direction of the roof. The curvature can vary over the extent of the glass composite 12 in both directions.

[0027] The glass composite 12 comprises two curved plate-shaped glass bodies 14 and 16 , between which a functional film 18 is arranged, which may be a heat protection film. The two glass bodies 14 and 16 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com