Wet dust collection apparatus

A technology of wet dedusting and equipment, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of high equipment cost, complex flue gas composition, and large body structure, and reduce equipment size and site occupancy , save equipment investment and power consumption, and save the effect of electrical control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

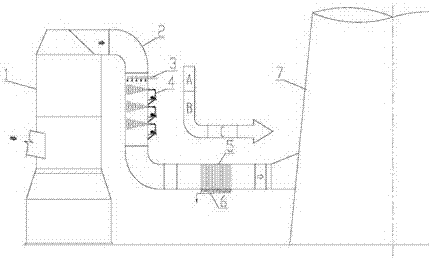

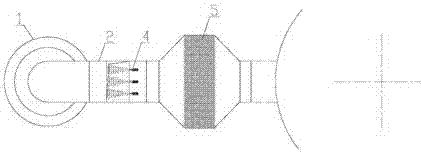

[0030] Please refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a specific embodiment of the wet dust removal equipment provided by the present invention; figure 2 for figure 1 A top view of the wet dedusting equipment shown.

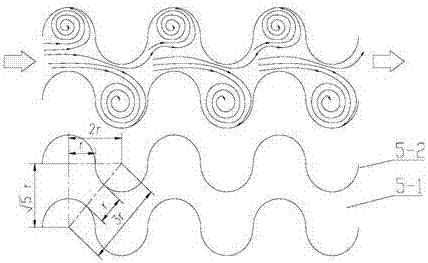

[0031] In a specific embodiment, the wet dedusting equipment provided by the present invention is arranged on the flue gas flow channel 2 behind the desulfurization absorption tower 1, and is mainly composed of an ultrasonic atomizer 3, an acoustic wave generator 4, and a droplet catcher 5. and the collection device 6, etc., the flue gas flow channel 2 includes a vertical flow channel and a horizontal flow channel, the ultrasonic atomizer 3 and the sound wave generator 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com