Multifunctional damping film for automobile and preparation method thereof

A multi-functional, damping adhesive technology, applied in adhesives, epoxy resin adhesives, natural rubber adhesives, etc., can solve problems such as increased stiffness, corrosion of body panels, and insufficient electrophoresis, achieving high damping coefficients and weight reduction , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

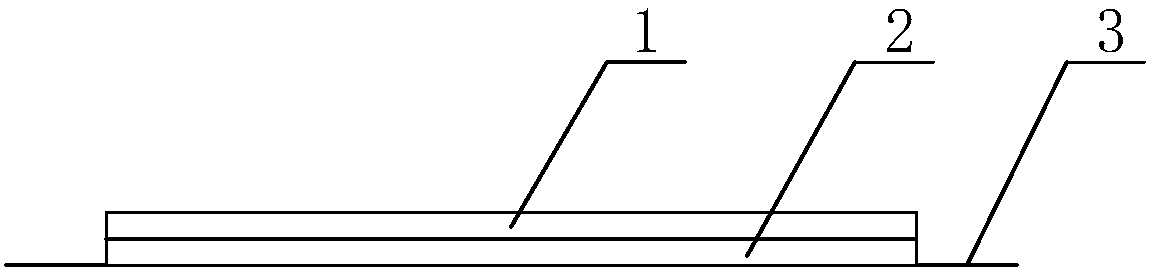

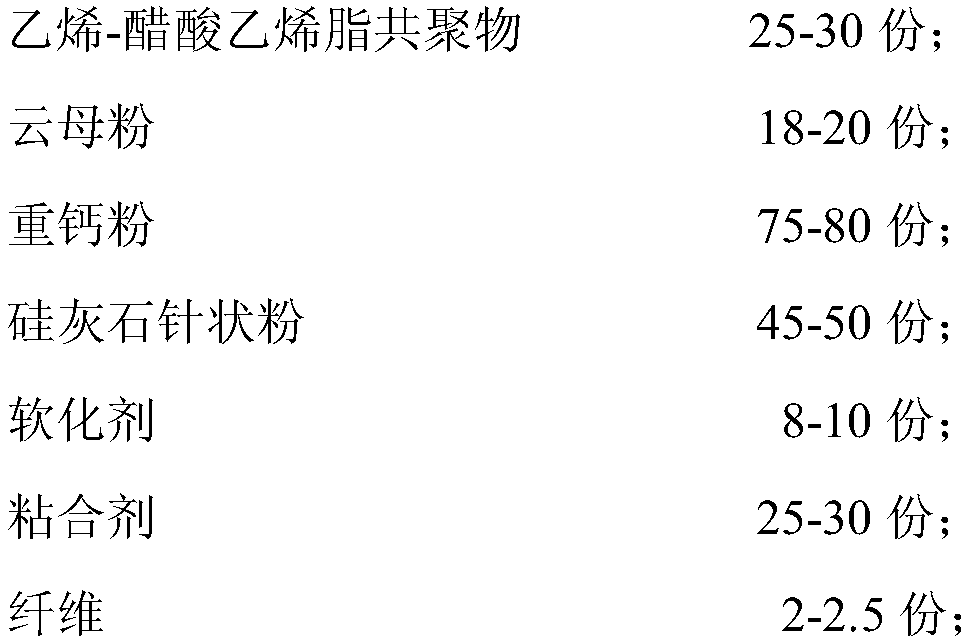

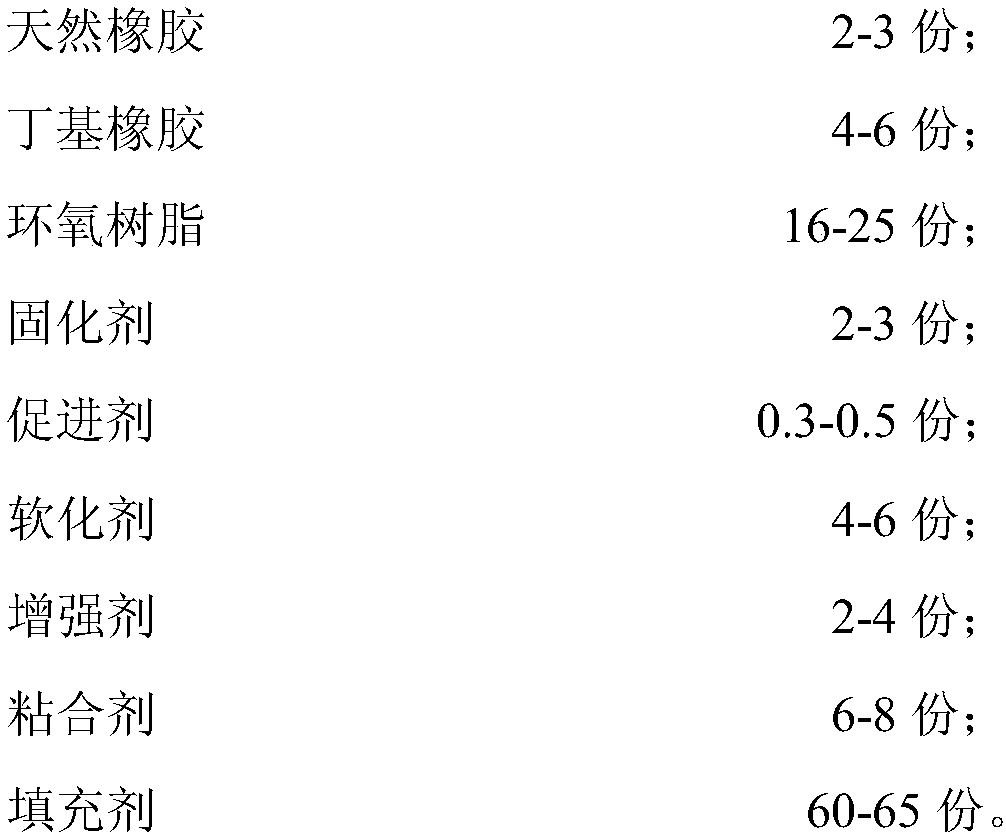

[0041] Such as figure 1 As shown, a multifunctional damping film for automobiles comprises a self-adhesive reinforcing adhesive layer 2, a damping adhesive layer 1 arranged on the upper surface of the reinforcing adhesive layer 2, and an anti-sticking adhesive layer arranged on the lower surface of the reinforcing adhesive layer 2. Layer 3, the raw material components and parts by weight of the damping rubber layer 1 are: 25 parts of ethylene-vinyl acetate copolymer, 18 parts of mica powder, 77 parts of heavy calcium powder, 45 parts of wollastonite needle powder, naphthene oil 8 parts, 25 parts of C5 petroleum resin, 2.2 parts of polyester fiber; the raw material components and weight parts of reinforcing adhesive layer 2: 2.5 parts of natural rubber, 5 parts of butyl rubber, 16 parts of epoxy resin, 2 parts of dicyandiamide , 0.3 parts of 3-phenyl-1,1-dimethylurea, 4 parts of naphthenic oil, 2 parts of carbon black, 6 parts of C5 petroleum resin, 60 parts of heavy calcium po...

Embodiment 2

[0043] Such as figure 1 As shown, a multifunctional damping film for automobiles comprises a self-adhesive reinforcing adhesive layer 2, a damping adhesive layer 1 arranged on the upper surface of the reinforcing adhesive layer 2, and an anti-sticking adhesive layer arranged on the lower surface of the reinforcing adhesive layer 2. Layer 3, the raw material components and parts by weight of the damping rubber layer 1 are: 28 parts of ethylene-vinyl acetate copolymer, 19 parts of mica powder, 80 parts of heavy calcium powder, 47 parts of wollastonite needle powder, naphthenic oil 9 parts, 28 parts of C5 petroleum resin, 2.5 parts of high-strength polypropylene fiber; raw material components and parts by weight of reinforcing adhesive layer 2: 3 parts of natural rubber, 6 parts of butyl rubber, 18 parts of epoxy resin, dicyandiamide 2.5 parts, 0.4 parts of 3-(4-chlorophenyl)-1,1-dimethylurea, 5 parts of naphthenic oil, 3 parts of carbon black, 7 parts of C5 petroleum resin, 62 p...

Embodiment 3

[0045] Such as figure 1 As shown, a multifunctional damping film for automobiles comprises a self-adhesive reinforcing adhesive layer 2, a damping adhesive layer 1 arranged on the upper surface of the reinforcing adhesive layer 2, and an anti-sticking adhesive layer arranged on the lower surface of the reinforcing adhesive layer 2. Layer 3, the raw material components and parts by weight of the damping rubber layer 1 are: 30 parts of ethylene-vinyl acetate copolymer, 20 parts of mica powder, 75 parts of heavy calcium powder, 50 parts of wollastonite needle powder, naphthene oil 10 parts, 30 parts of C5 petroleum resin, 2 parts of polyacrylonitrile fiber; The raw material components and parts by weight of reinforcing adhesive layer 2: 2 parts of natural rubber, 4 parts of butyl rubber, 25 parts of epoxy resin, 3 parts of dicyandiamide 0.5 parts of 3-p-anisyl-1,1-dimethylurea, 6 parts of naphthenic oil, 4 parts of carbon black, 8 parts of C5 petroleum resin, and 65 parts of calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com