Electrical machinery planetary mechanism stepless gear system

A planetary mechanism, continuously variable speed technology, applied in the field of vehicle transmission, can solve the problems of complex coupling effect of clamping force and speed ratio control, low ability to transmit power and torque, complex structure of hydraulic system, etc. The effect of high transmission power and torque, stable and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

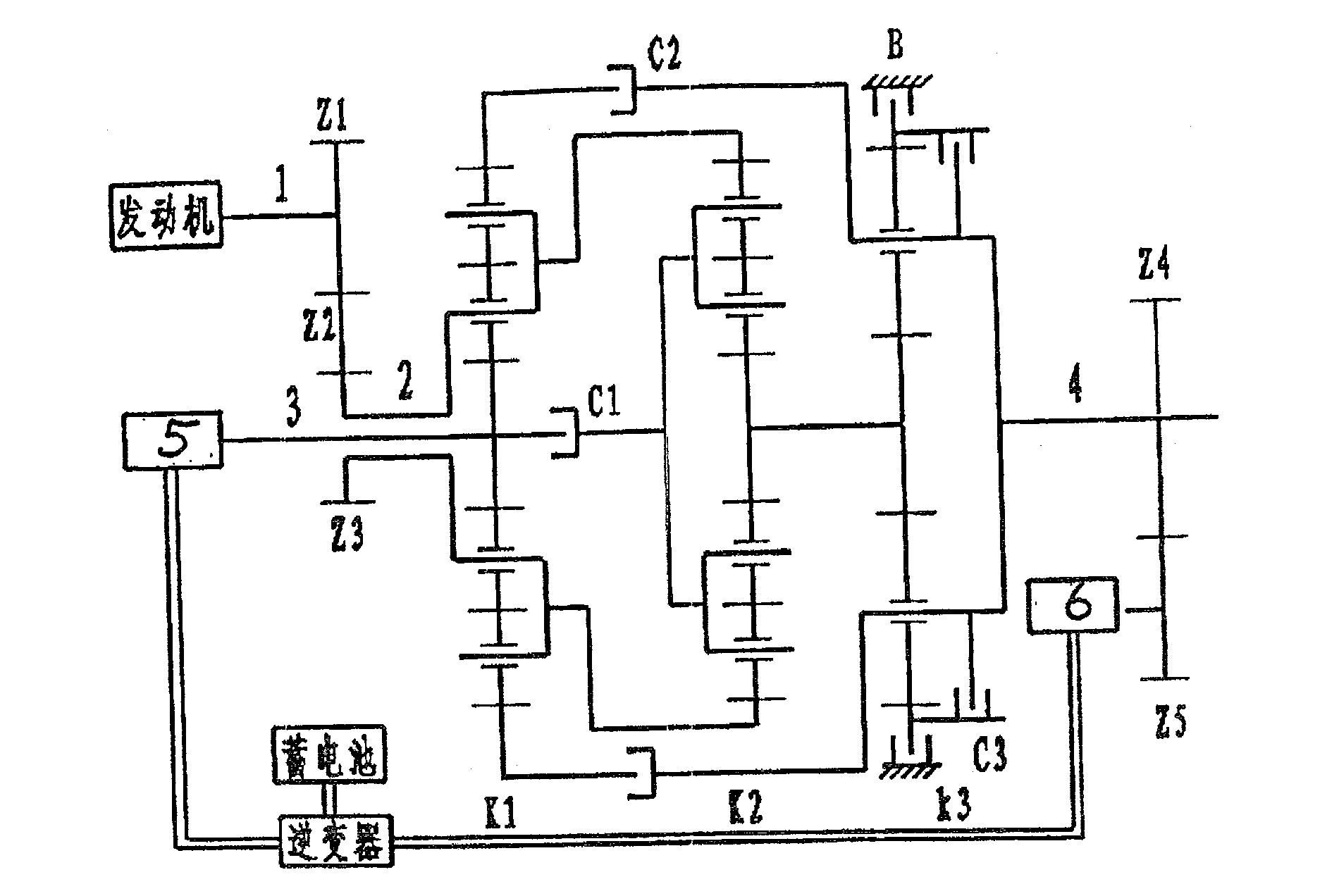

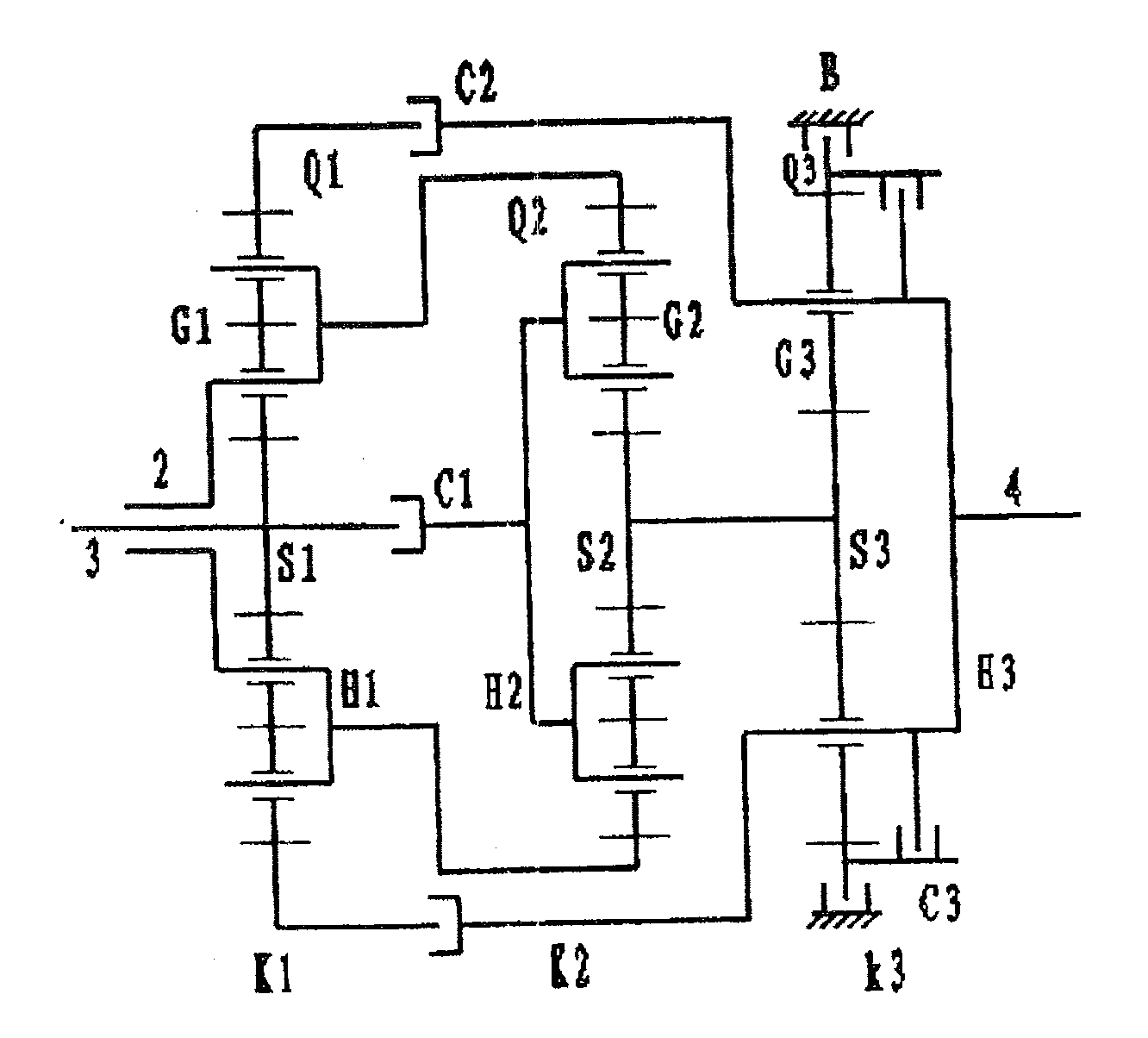

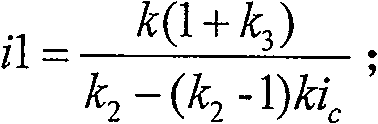

[0026] as attached figure 1 As shown, the electromechanical planetary mechanism continuously variable transmission system consists of the first gear Z1, the idler gear Z2 and the second gear Z3, the planetary mechanism, the first input shaft 1, the sleeve shaft 2, the second input shaft 3, the output The shaft 4, the third gear Z4 and the fourth gear Z5 meshing with each other, the first motor 5, the second motor 6 (which also has the function of generating electricity), an inverter and a storage battery are composed. Wherein, the sleeve shaft 2 and the second input shaft 3 are concentric, and the first input shaft 1 and the second input shaft 3 are respectively connected to the output shaft of the engine and the output shaft of the first electric motor 5 . as attached figure 2As shown, the planetary mechanism is composed of a first clutch C1, a second clutch C2, a third clutch C3, a brake B, a first double planetary gear train K1, a second double planetary gear train K2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com