Single-stage planetary gear backflow type hydraulic mechanical stepless transmission system

A planetary gear and hydraulic machinery technology, applied in the field of mechanical transmission, can solve problems such as unsatisfactory work and low overall efficiency, and achieve the effects of wide variation range, reduced efficiency, and large torque ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

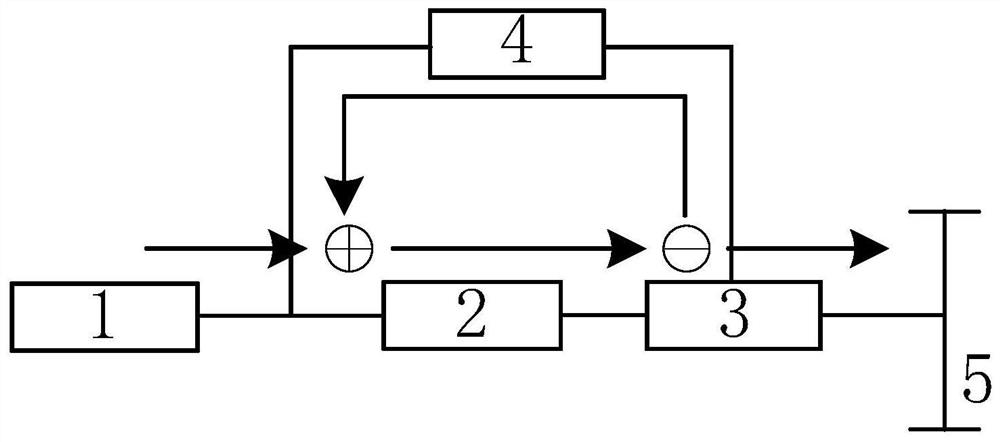

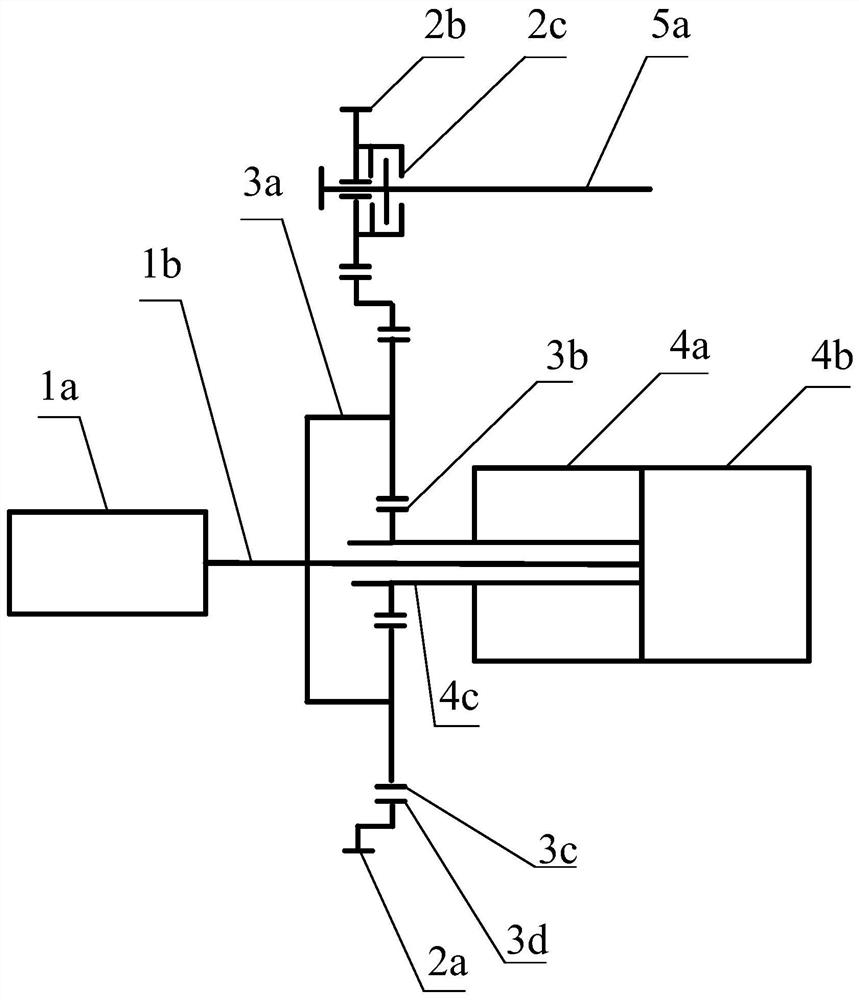

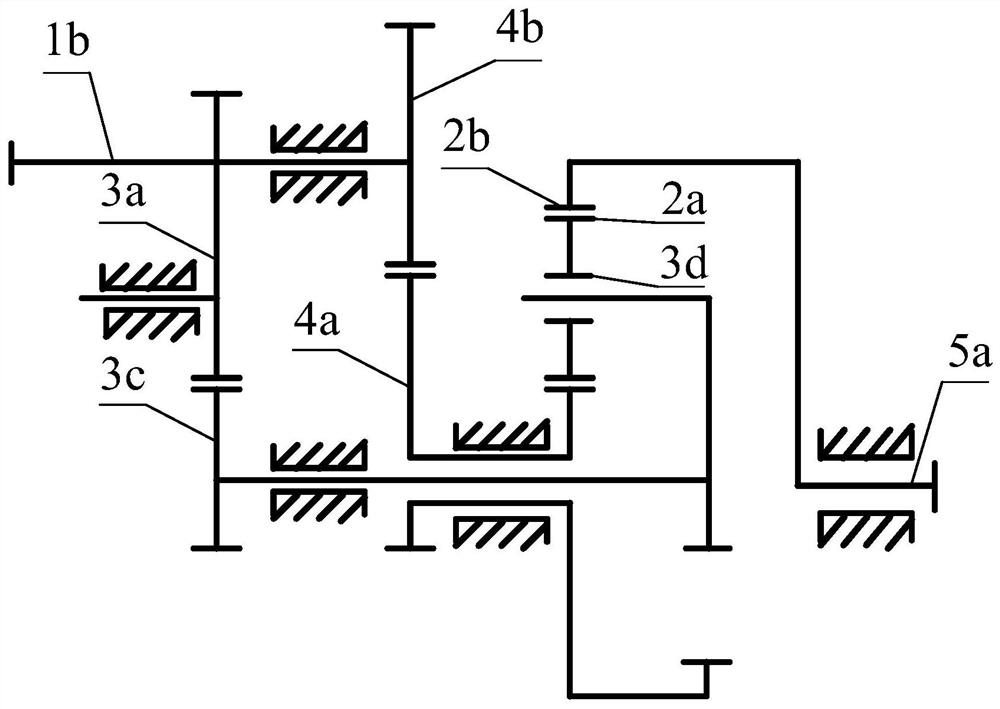

[0030] like figure 1 and figure 2 As shown, a single-stage planetary gear return type hydraulic mechanical stepless transmission system mainly includes a power input device 1, a planetary row 3, a hydraulic return device 4 and a power output device 5. The power input device 1 includes a power input device driven by an engine 1a. The input shaft 1b, the hydraulic return device 4 includes a variable displacement pump 4a and a hydraulic quantitative motor 4b, and the planetary row 3 includes a planetary carrier 3a, a sun gear 3b, a planetary gear 3c and a ring gear 3d which are adapted to each other.

[0031] The output power of the input shaft 1b is transmitted to the planetary gear 3c through the planet carrier 3a, and the planetary gear 3c transmits part of the power to the power output device 5 through the ring gear 3d, which is output from the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com