Circular pipe butt welding rapid positioning device and circular pipe butt welding method

A positioning device and butt welding technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, poor overall accuracy, and difficulty in ensuring coaxiality, and reduce the labor intensity and difficulty of workers , The size of the weld gap is accurate, and the effect of ensuring the coaxiality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

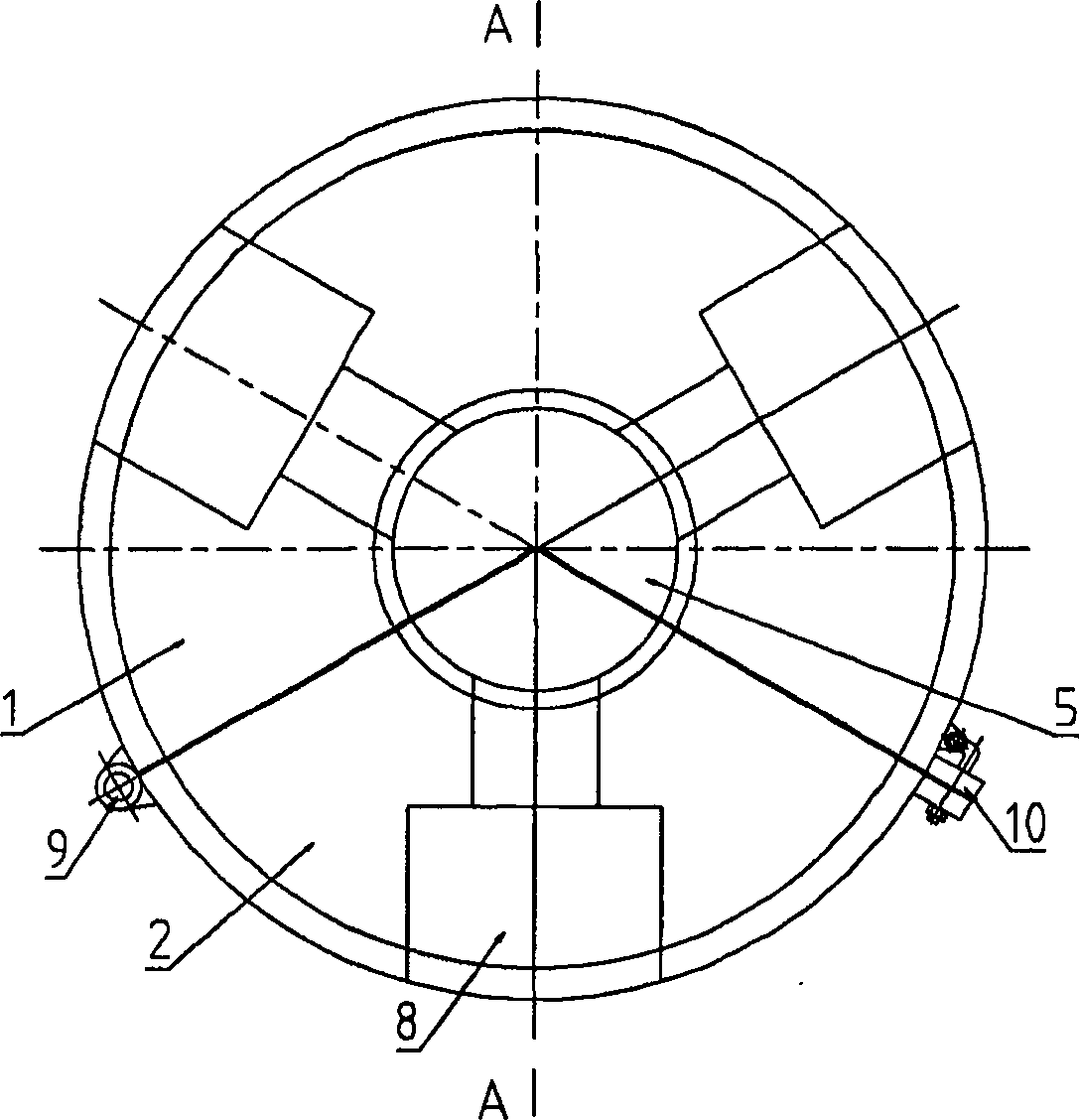

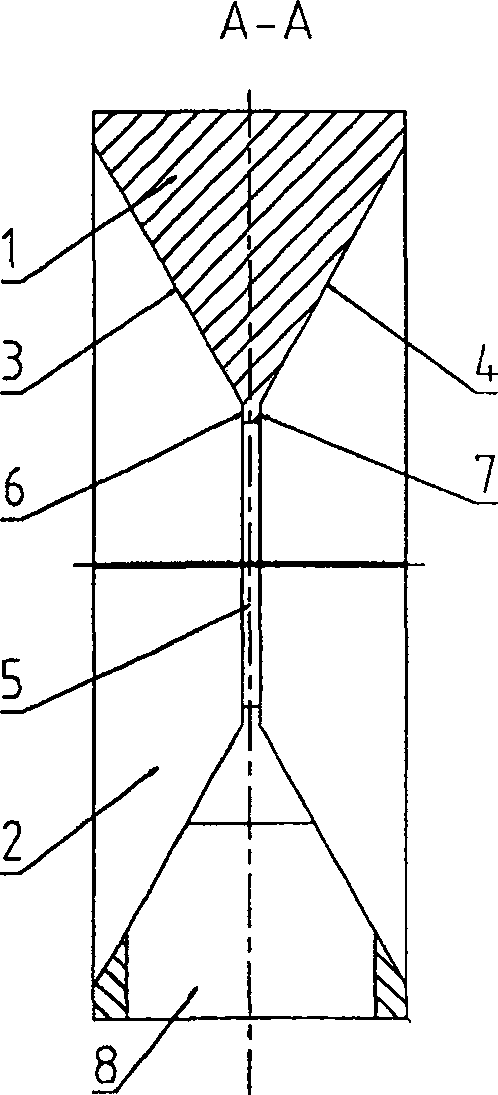

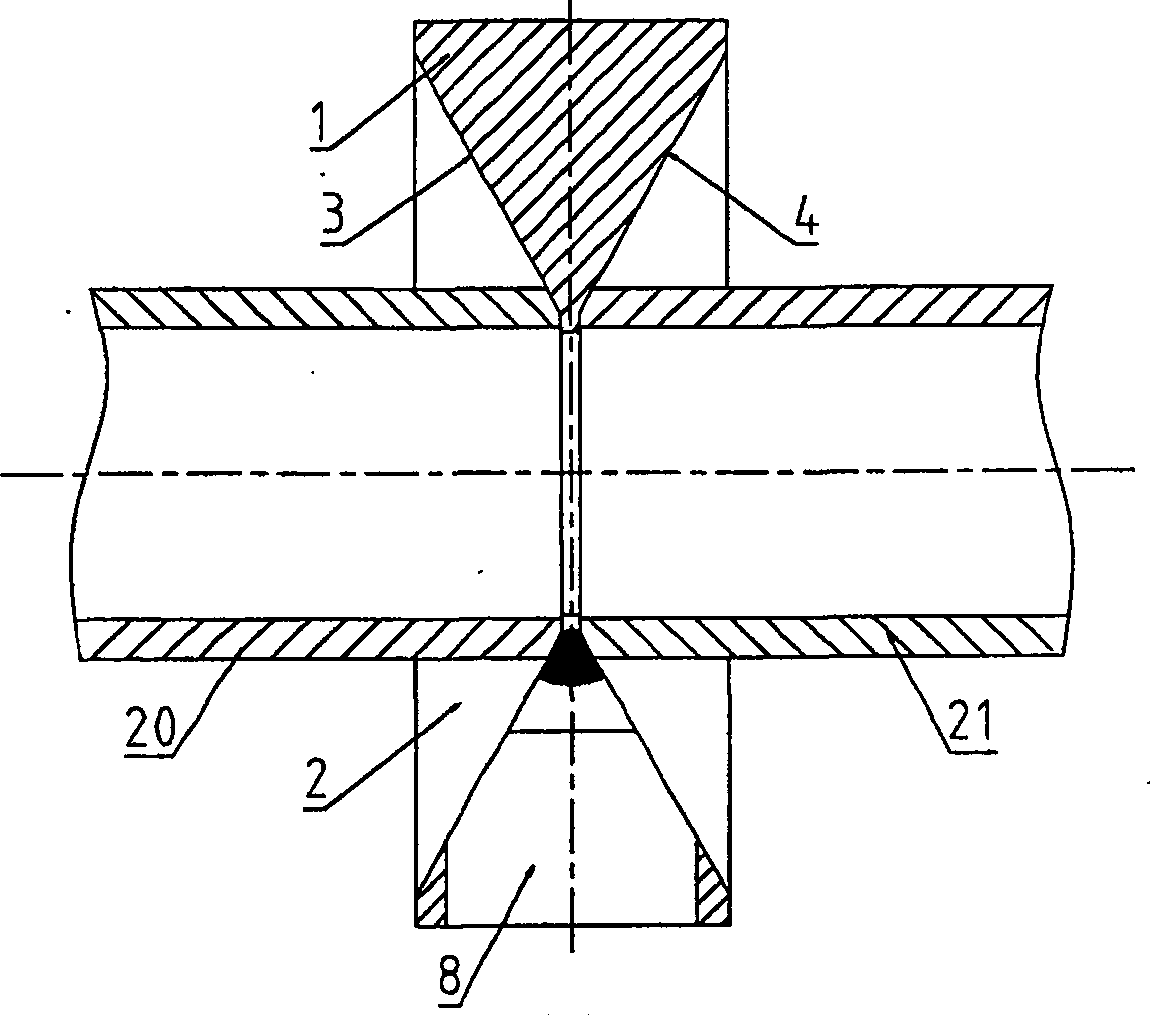

[0020] Such as figure 1 , figure 2 As shown, the positioning sleeve of the round pipe butt welding quick alignment and positioning device is a cylindrical structure composed of a half-positioning sleeve 1 of one-third part and a half-positioning sleeve 2 of two-thirds part. , the axial direction of the positioning sleeve has left and right symmetrical taper holes 3, 4, and there is a coaxial round hole 5 between the two taper holes, and the round hole 5 connects the two taper holes 3, 4 to form two left and right step seams 6, 7 , there are three evenly distributed radially stepped holes 8 intersecting with the two tapered holes 3, 4, and round holes 5 on the outer circumference of the positioning sleeve; the joints on one side of the two half positioning sleeves 1, 2 are hinged by a hinge 9 ; Clamping device 10 includes two half-positioning sleeves 1, 2 on the other junction of the ear plate and screw nut mechanism respectively provided on the ear plate.

[0021] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com