Compressor capacity control valve and control method and application thereof

A technology for compressor capacity and control valves, which is applied in pump control, mechanical equipment, machines/engines, etc., can solve problems such as the inability of four-way valves, and achieve the effects of low production cost, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

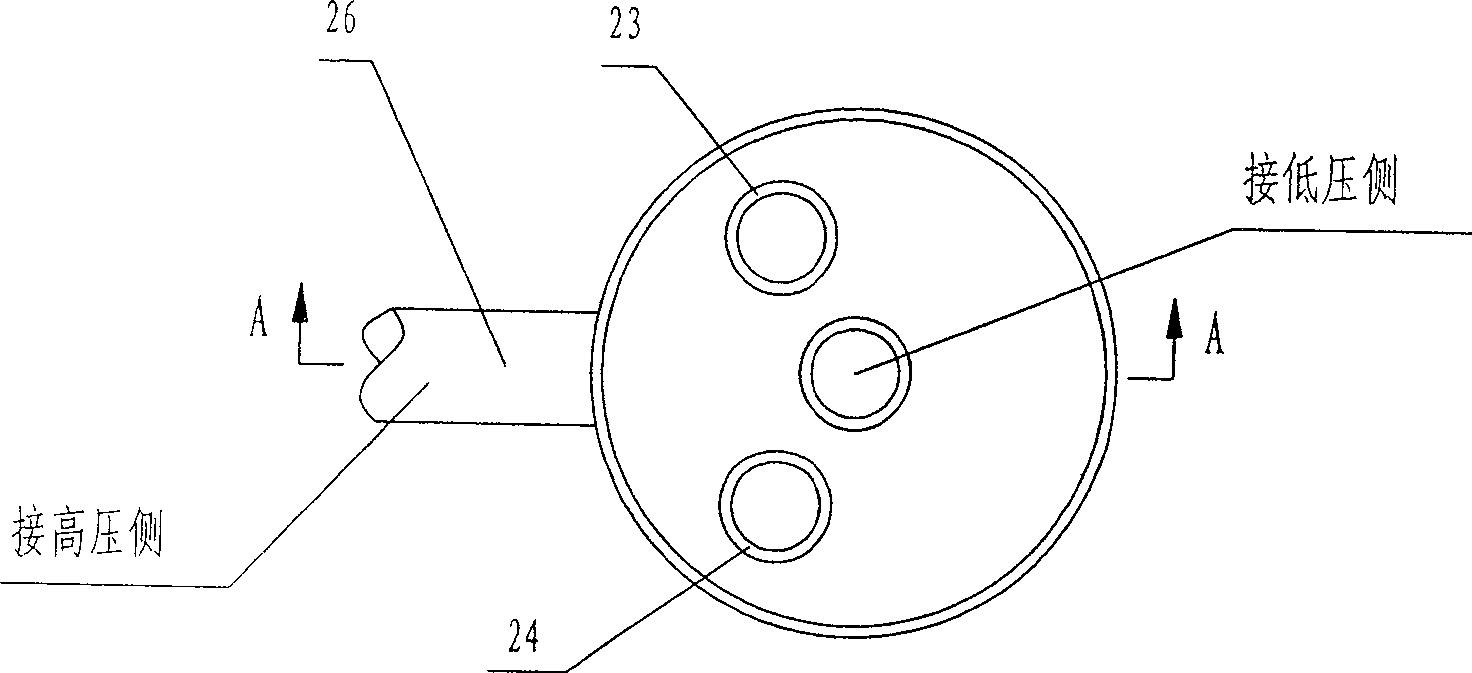

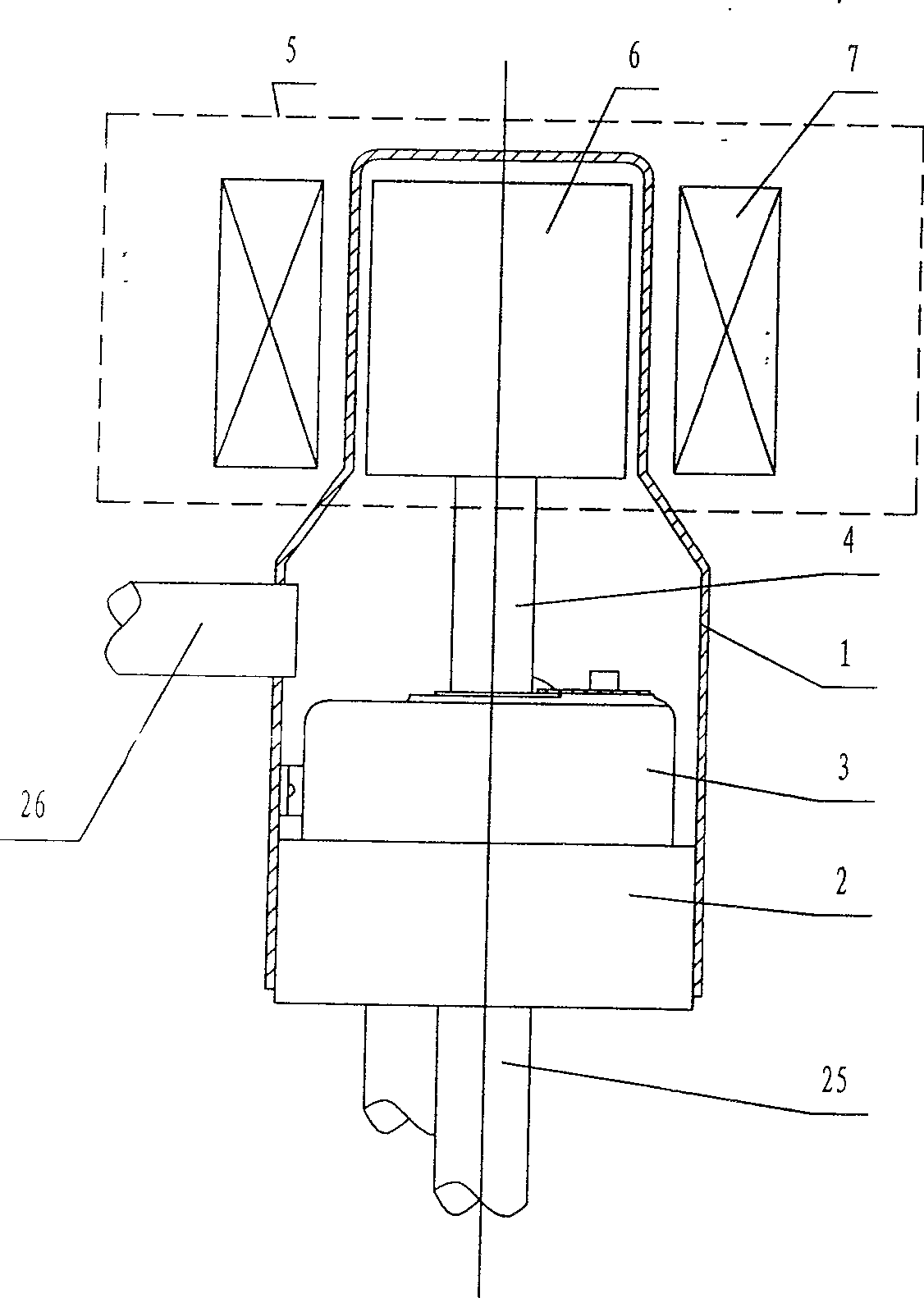

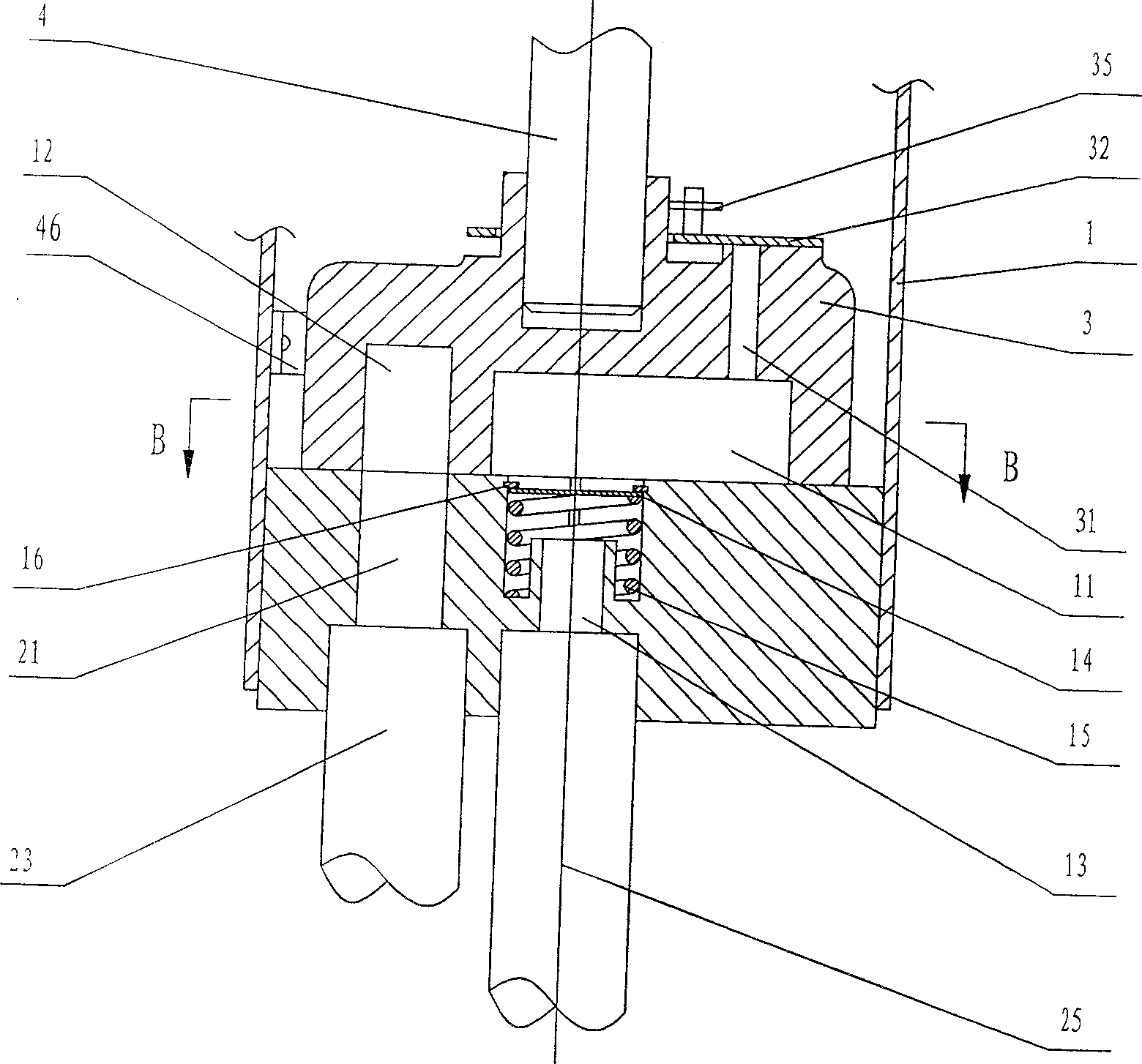

[0044] In the figure: 1 is the housing, 2 is the valve seat, 3 is the slider, 4 is the crankshaft, 5 is the stepper motor, 6 is the motor rotor, 7 is the coil, 11 is the low pressure cavity, 12 is the high pressure cavity, 13 14 is a one-way valve, 15 is a coil spring, 16 is a retaining ring, 21 is a first pressure switching hole, 22 is a second pressure switching hole, 23 is a first connecting pipe, 24 is a second connecting pipe, 25 is the third connecting pipe, 26 is the fourth connecting pipe, 31 is the balance hole, 32 is the pilot valve, 33 is the arm, 34 is the limit plate, 35 is the stop pin, 36 is the arm block, 41 is the leaf spring, 42 is a disc, 43 is a square hole, 44 is a lifting hook, 45 is a disc stopper, 46 is a slider stopper, 47 is a fixed stopper, 51 is a tapered protrusion, and 52 is a horizontal hole.

[0045] see Figure 1-Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com