LCD glass oven system door and apparatus for controlling the same

A technology for control devices and ovens, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., and can solve the problem of reducing the space for accommodating glass substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

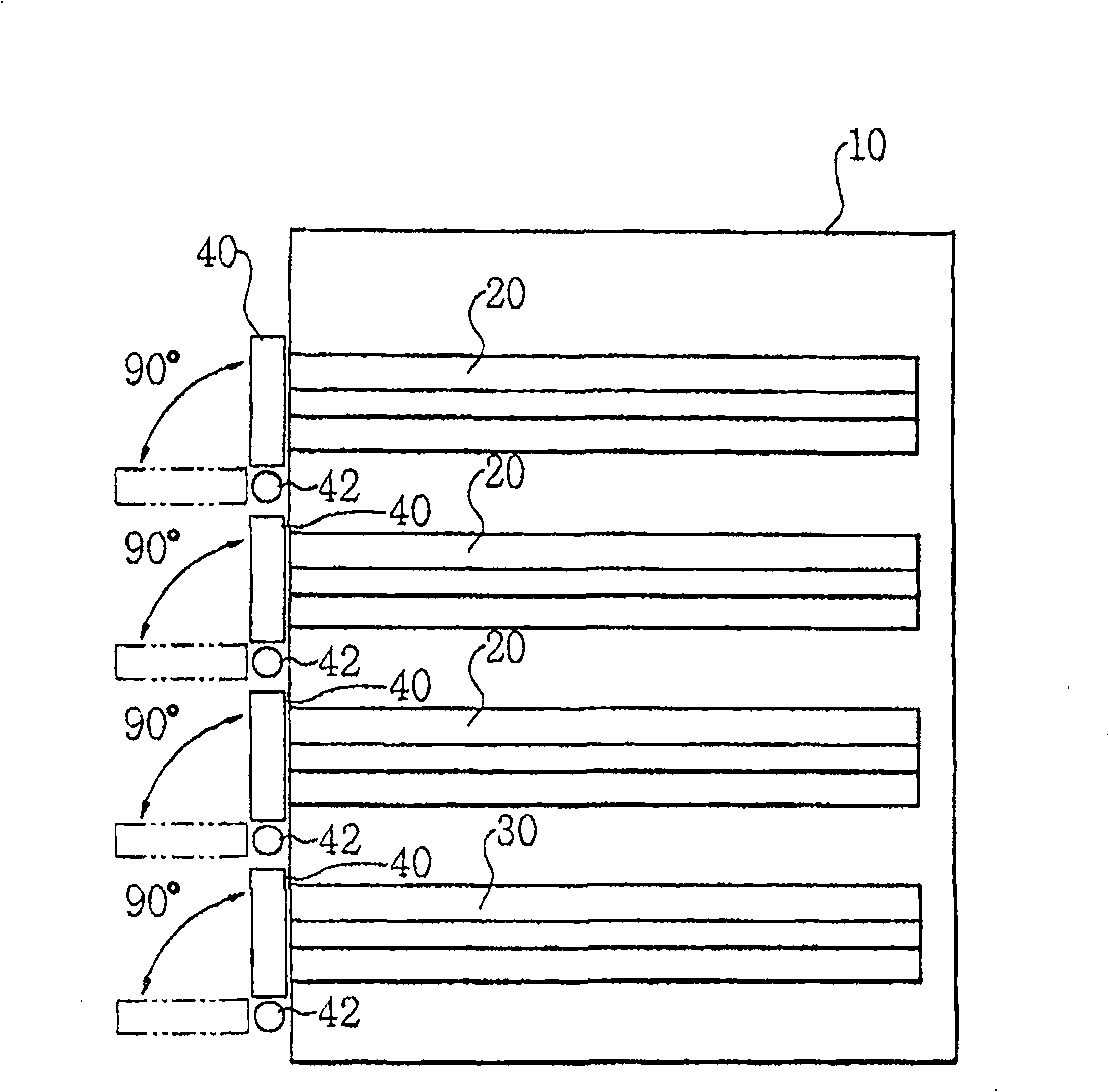

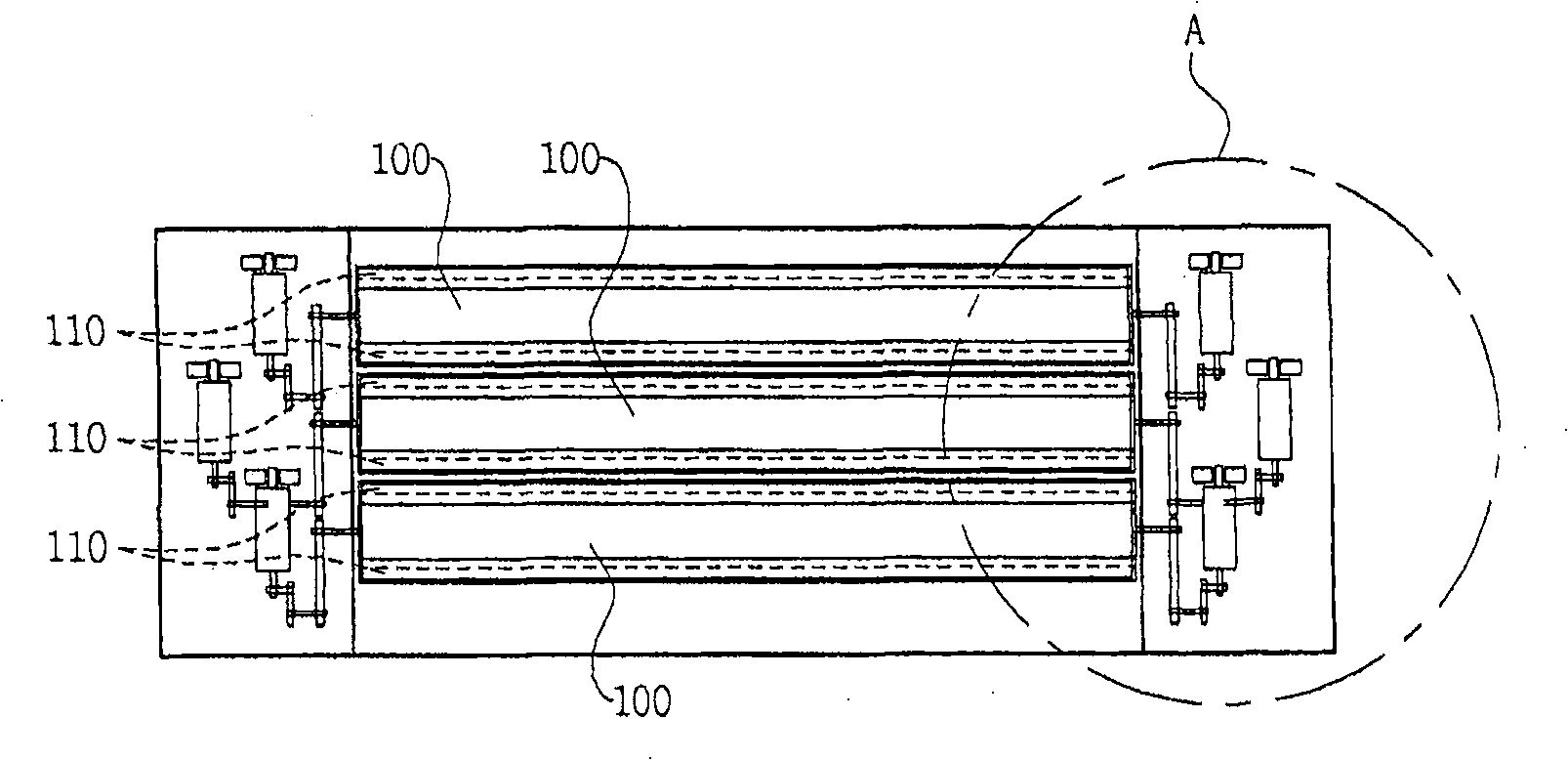

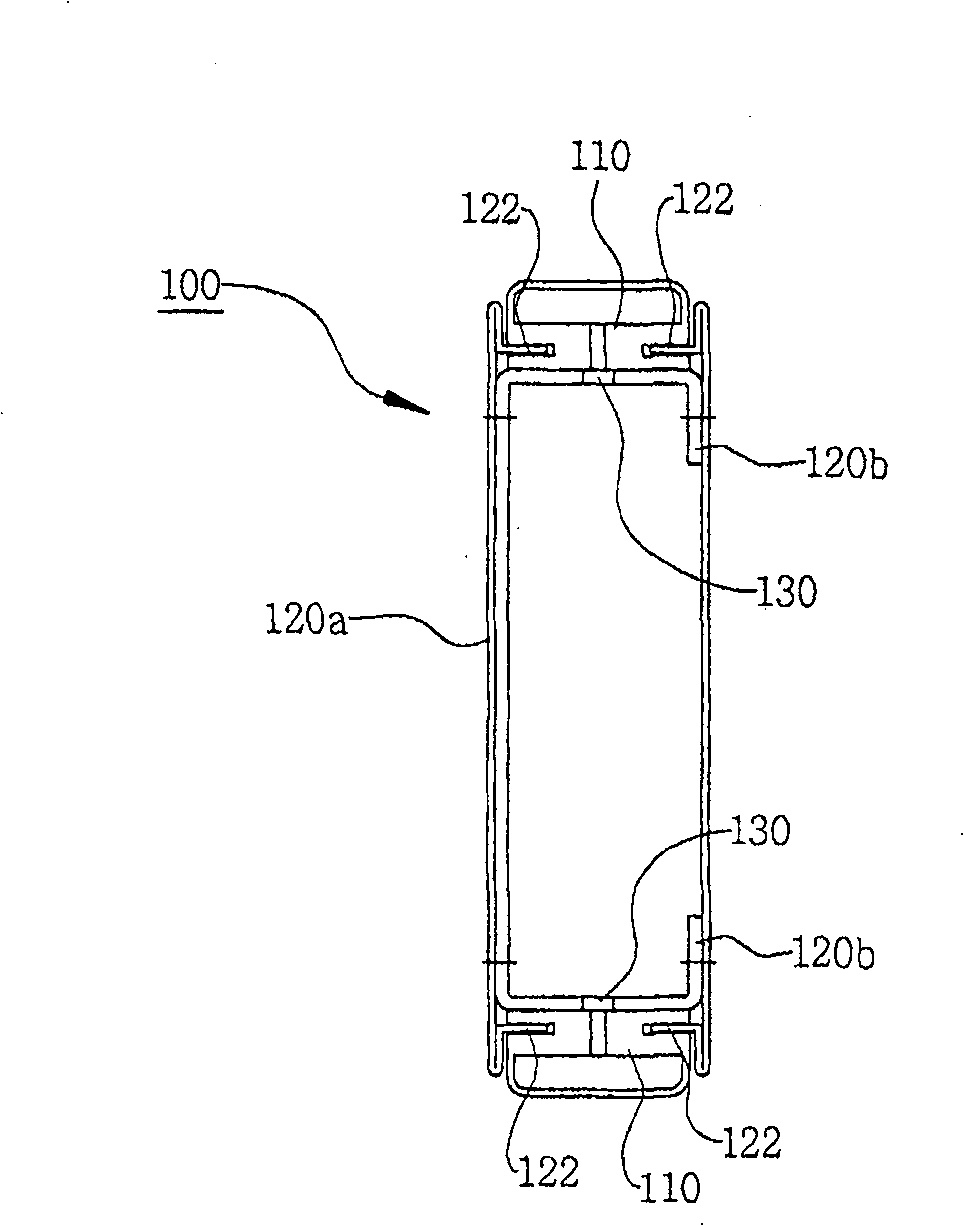

[0049] figure 2 is a front view showing an LCD glass oven system door and its control device according to an embodiment of the present invention. image 3 is an enlarged side cross-sectional view of an LCD glass oven system door in accordance with the present invention. Figure 4 It is a diagram showing the air supply and exhaust device of the LCD glass oven system door according to the present invention. Figure 5 yes figure 2 Enlarged view of circled part A in .

[0050] refer to Figures 2 to 4, the LCD glass oven system door 100 according to the embodiment of the present invention includes: door frames 120a, 120b; two air filling parts 110 respectively arranged in the upper end and the lower end of the door frames 120a and 120b; a vent 130 through which the air is ventilated. port 130 to supply air to the corresponding air filling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com