High-precision quick level adjusting device

A leveling device and high-precision technology, applied in the directions of instruments, electrical components, instrument parts, etc., can solve the problems of insufficient stability of the leveling mechanism and low leveling accuracy, and achieve the effect of eliminating gaps and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The high-precision fast leveling device of the present invention will be described in further detail below in conjunction with a preferred embodiment.

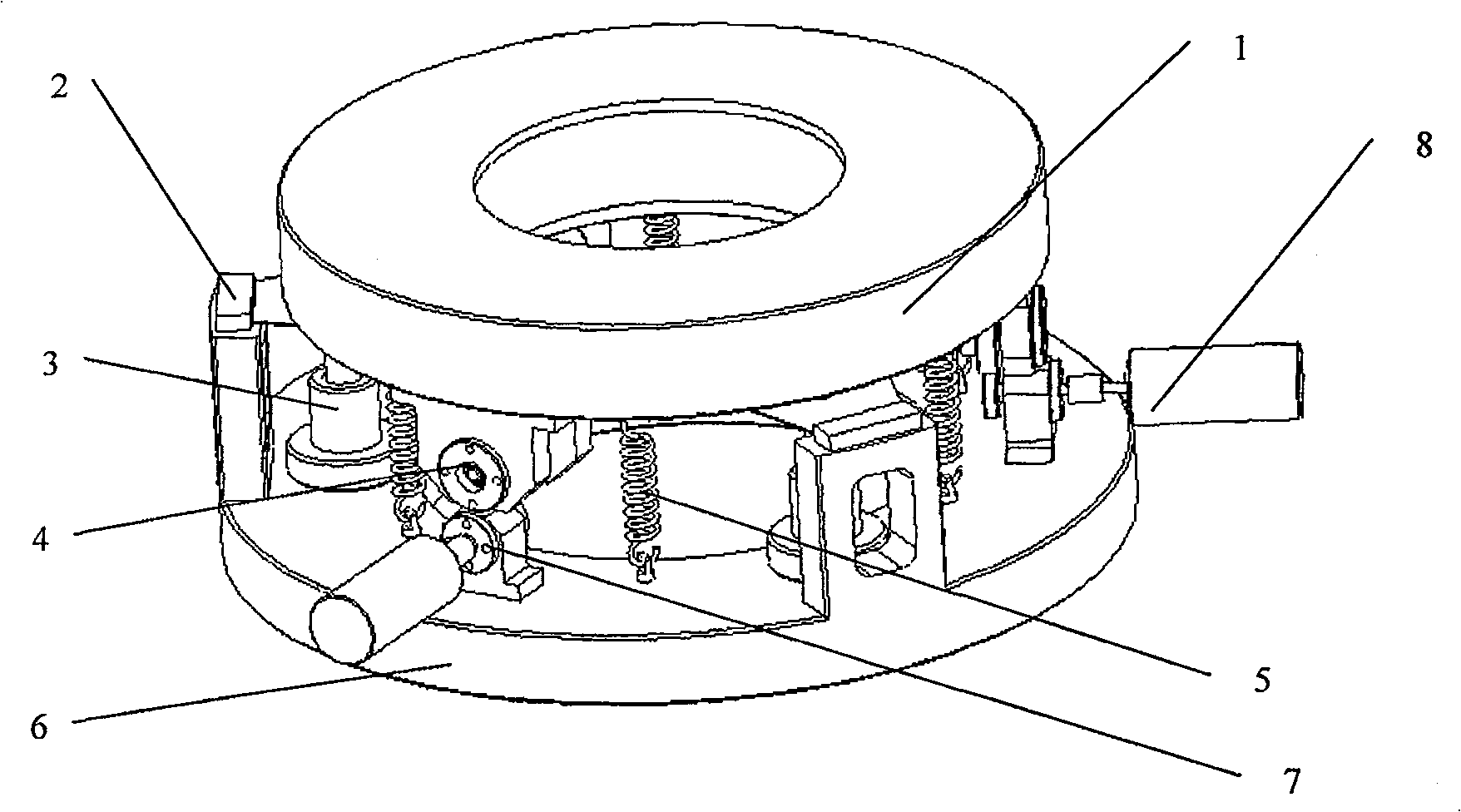

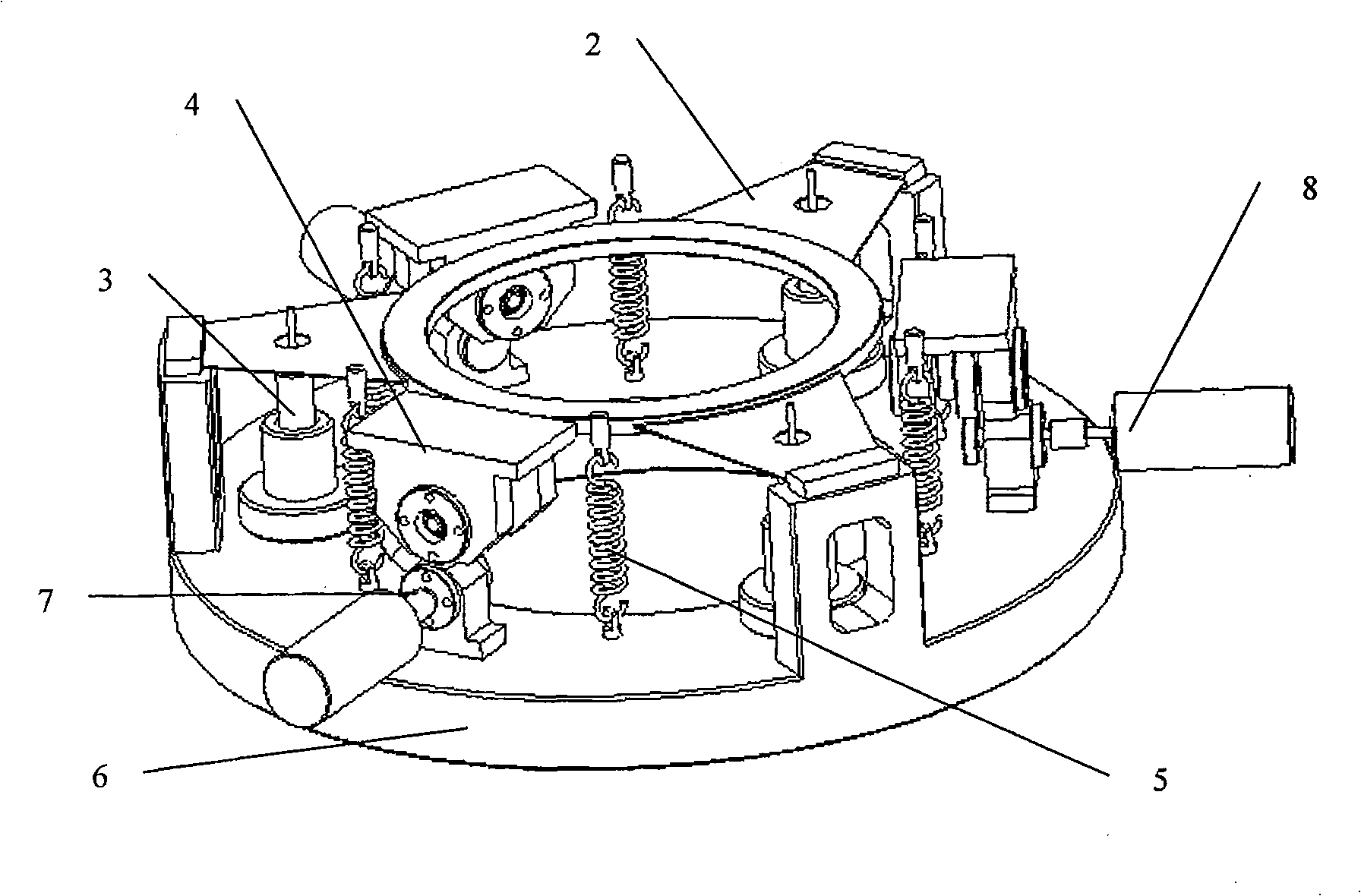

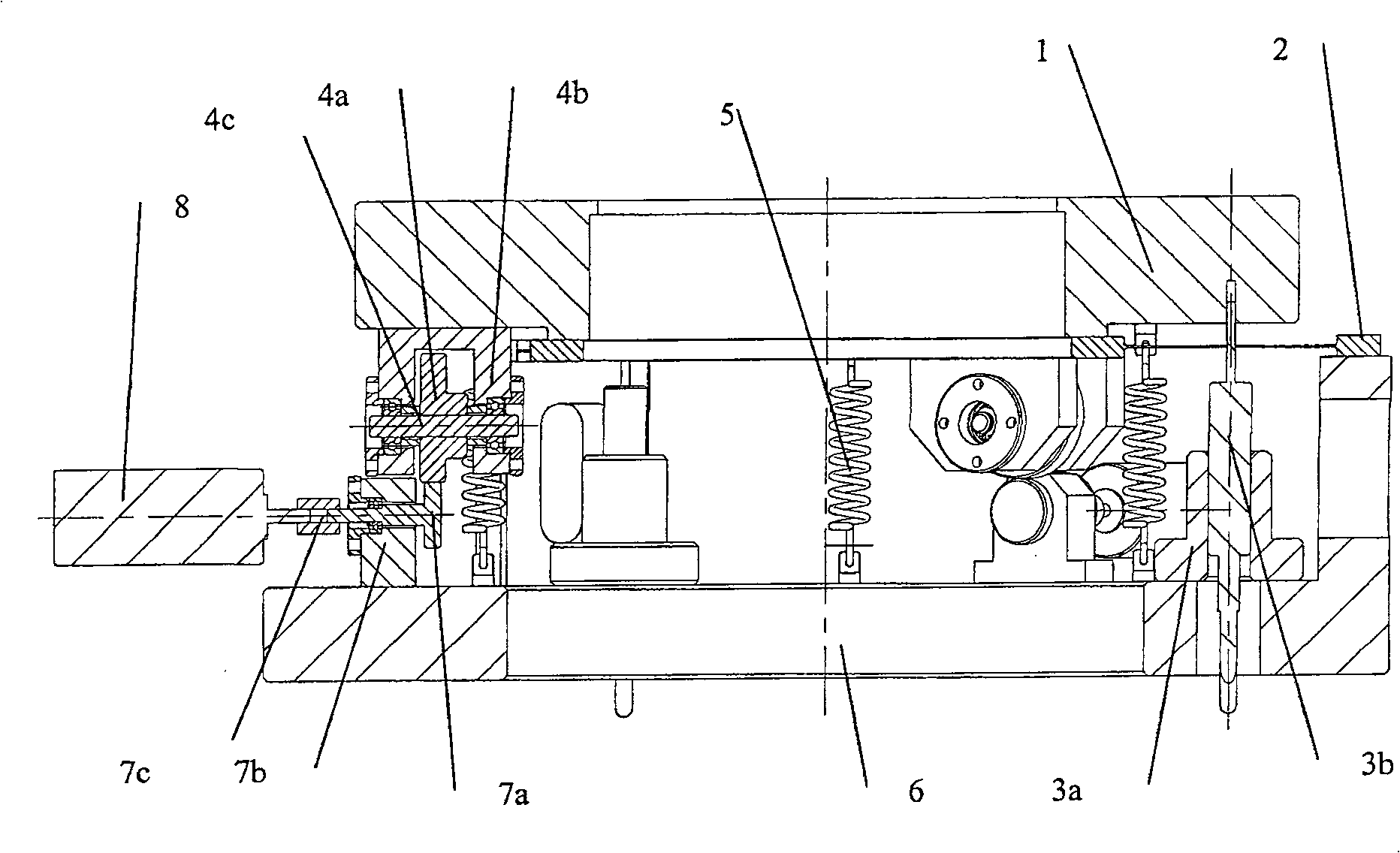

[0021] Please combine Figure 1 to Figure 3 As shown, the high-precision fast leveling device of the present invention includes an adjustment platform 1, an installation base 6, and multiple sets of parallel reeds 2 installed between the adjustment platform 1 and the installation base 6, an online position measurement sensor assembly 3, an eccentric wheel / Cam assembly 4 , pretension tension spring 5 , executive wheel assembly 7 and drive motor 8 .

[0022] In this embodiment, both the adjustment platform 1 and the installation base 6 are circular, and three sets of parallel reeds 2 are used for connection. between 6. Correspondingly, the leveling device also includes three sets of on-line position measurement sensor assemblies 3, eccentric wheel / cam assembly 4 and executive wheel assembly 7, the on-line position meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com