Nano-level formaldehyde-free coating printing-dyeing adhesvie, and its preparing method and use

A kind of adhesive, nano-level technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of high energy consumption, hard hand feeling of dyed fabrics, etc., and achieve the effect of soft hand feeling of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

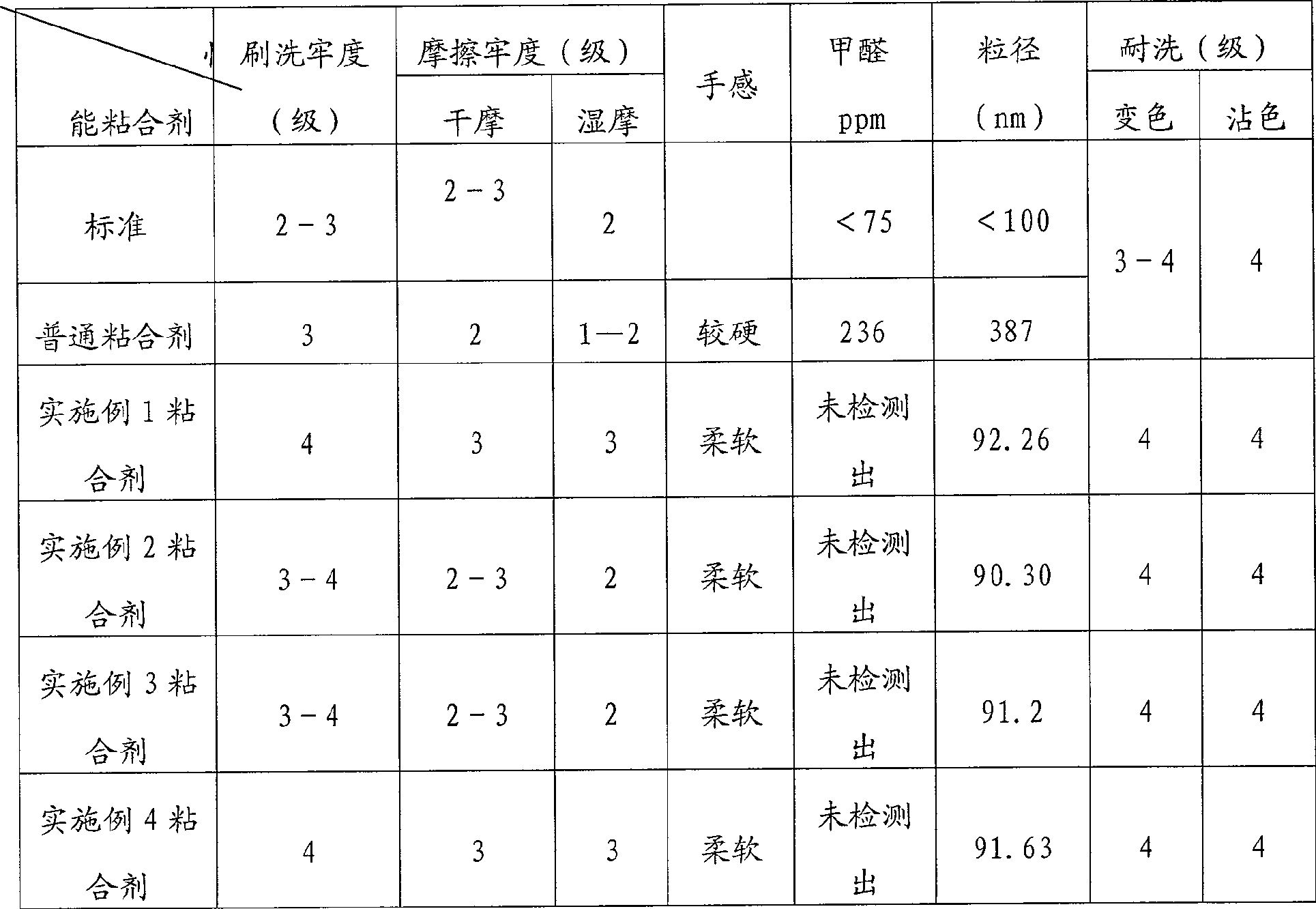

Examples

Embodiment 1

[0122] 1. Preparation of N-glycidyl acrylamide crosslinking monomer

[0123] Add epichlorohydrin 23g, acrylamide 18g, organic alcohol (such as ethanol 21g), catalyst (such as alkylbenzenesulfonic acid) 0.15g and polymerization inhibitor ( For example: 0.1g of phenol), after reacting at 60-80°C for a certain period of time (about 4 hours), distill off the organic alcohol under reduced pressure to obtain N-glycidyl acrylamide crosslinking monomer.

[0124] 2. Synthesis of nano-scale formaldehyde-free paint printing and dyeing adhesive

[0125] A. Preparation of nuclear microemulsion: Add 20g of butyl acrylate, 10g of 2-ethylhexyl acrylate, 1g of methacrylic acid, 2.5g of composite reactive emulsifier, unsaturated strong hydrophilic monomer into a 250ml three-necked flask (eg: HR 1 C=CHR 2 SO 3 Na) 1.5g, deionized water 62g, and then heated to 40-60°C for high-speed emulsification for 10-30 minutes to obtain a nuclear microemulsion;

[0126] B. Preparation of shell microemul...

Embodiment 2

[0130] The preparation of N-glycidyl acrylamide crosslinking monomer, emulsion preparation and adhesive synthesis process are the same as in Example 1, and its components are as follows:

[0131] A. Nuclear microemulsion: 15g butyl acrylate, 8g 2-ethylhexyl acrylate, 0.8g acrylic acid, 2.0g composite reactive emulsifier, unsaturated strong hydrophilic monomer, such as: HR 1 C=CHR 2 SO 3 Na) 1.2g, deionized water 66g;

[0132] B. Shell microemulsion: formaldehyde-free self-crosslinking monomer N-glycidyl acrylamide 3g, acrylic acid 1.1g, methyl methacrylate 5.4g, styrene 4.8g, acrylonitrile 3.2g, acrylamide 2.0g, Composite reactive emulsifier 1.5g, unsaturated strong hydrophilic monomer (such as: HR 1 C=CHR 2 SO 3 Na) 1.0g, deionized water 66g;

[0133] C, initiator: potassium persulfate 0.4g, water 19g;

[0134] D. During the synthesis process, 3.2 g of vinyltriethoxysilane was added.

Embodiment 3

[0136] The preparation of N-glycidyl acrylamide crosslinking monomer, emulsion preparation and adhesive synthesis process are the same as in Example 1, and its components are as follows:

[0137] A. Nuclear microemulsion: 18g butyl acrylate, 5g 2-ethylhexyl acrylate, 1.0g acrylic acid, 2.0g composite reactive emulsifier, unsaturated strong hydrophilic monomer, such as: HR 1 C=CHR 2 SO 3 Na) 1.2g, deionized water 66g;

[0138] B. Shell microemulsion: formaldehyde-free self-crosslinking monomer N-glycidyl acrylamide 4g, acrylic acid 1.1g, methyl methacrylate 8.3g, styrene 5.1g, acrylamide 2.0g, composite reactive emulsifier 1.5g, unsaturated strong hydrophilic monomer (such as: HR 1 C=CHR 2 SO 3 Na) 1.0g, deionized water 65g; C, initiator: potassium persulfate 0.32g, water 19g;

[0139] D. During the synthesis process, 4.0 g of vinyltriethoxysilane was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com