Glue spreading system glass turnover mechanism

A turning mechanism and gluing technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of increased equipment cost, large work space, complex system, etc., and achieve avoidance of interference, high work efficiency, and work The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

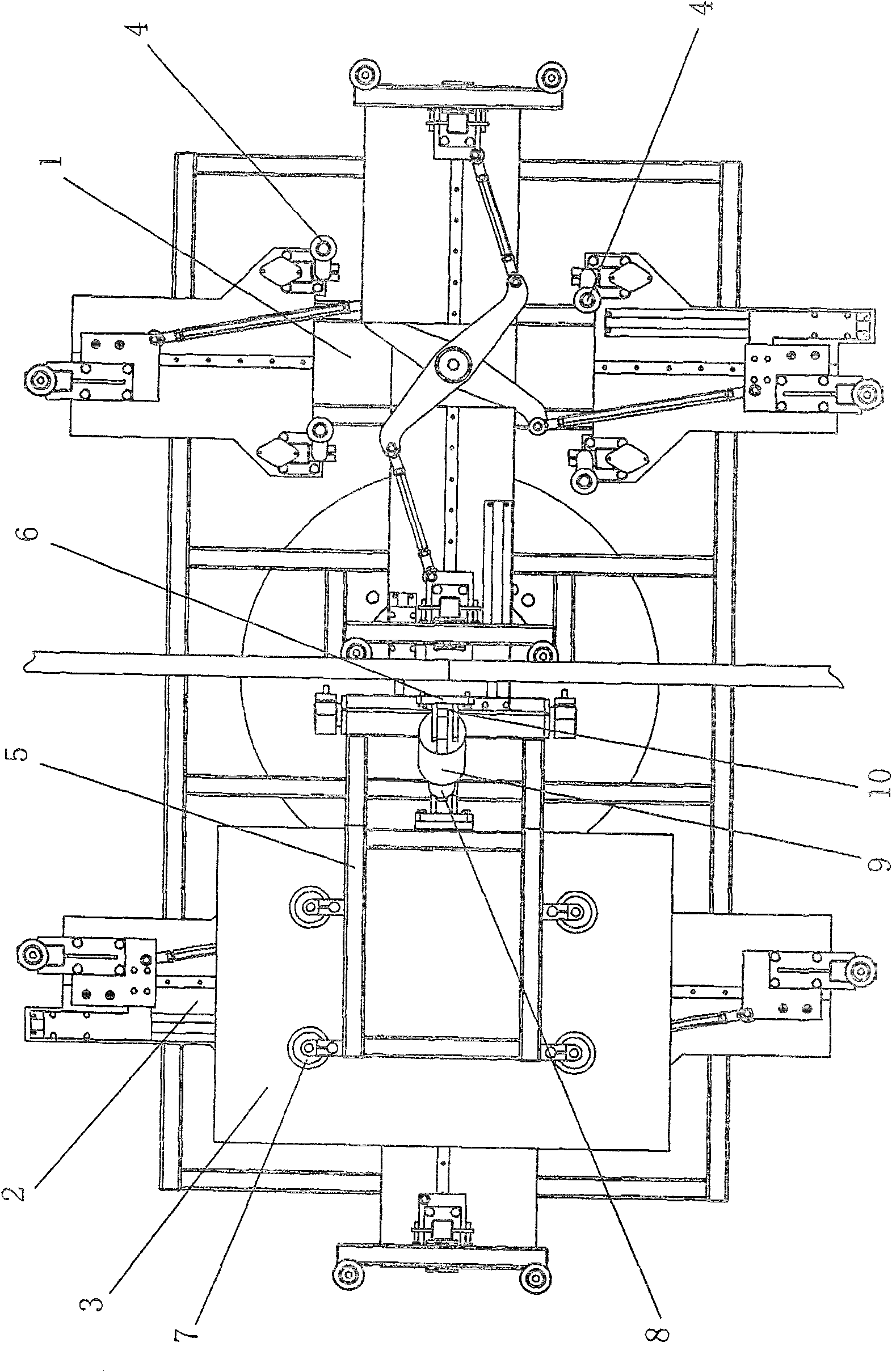

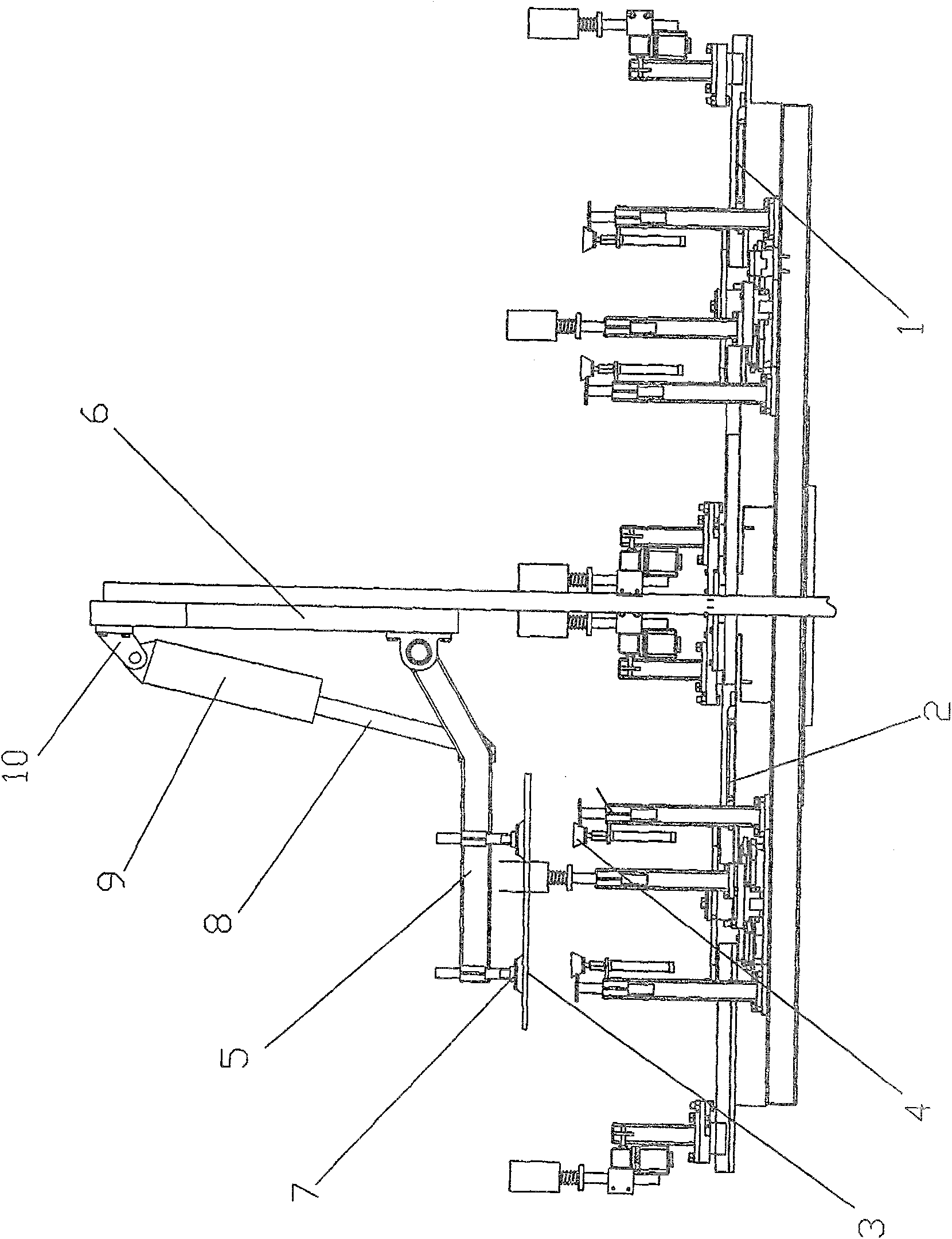

[0025] see figure 2 , according to the existing system structure, the gluing workstation has a rotary table, which is a symmetrical structure with a center of rotation. Among its symmetrically arranged two ends, one end is the measuring table 1, and the other end is the gluing table 2.

[0026] The glued glass 3 is first placed on the measuring table 1 located at the right end of the rotary table, and the measurement of the glued glass is completed on the measuring table 1, and the system completes the glued glass according to the measured characteristic values of the glued glass. The identification of the glass type, and then, the bottom vacuum suction cup 4 located under the glued glass on the measuring table 1 and positioned at the four corners of the glued glass clamps the glued glass on the measuring table 1 by vacuum suction. Then, through the 180-degree rotation of the rotary table, turn the measuring table 1 located at the right end to the left end of the rotary ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com